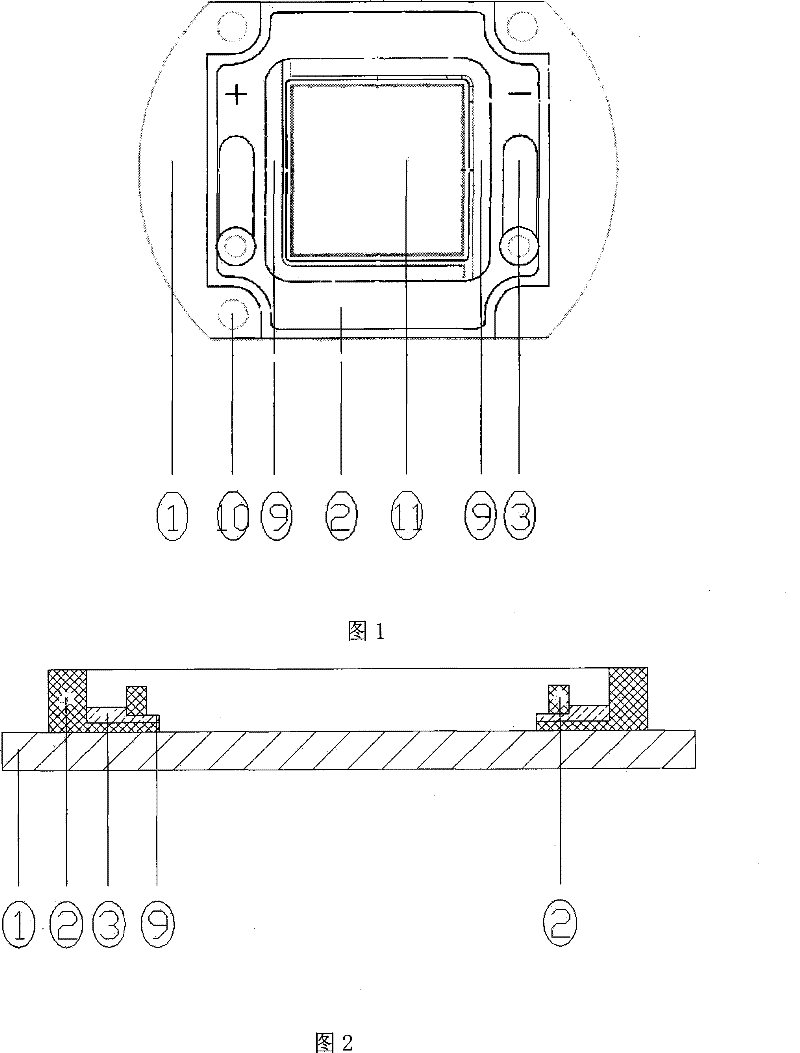

Ultra-high-power LED die set light source structure

A technology of LED modules and ultra-high power, applied in the direction of semiconductor devices, electrical components, circuits, etc., can solve the problems of difficult chip size, low LED chip power, difficult LED lighting, etc., to meet psychological needs, structure Simple, highly marketable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

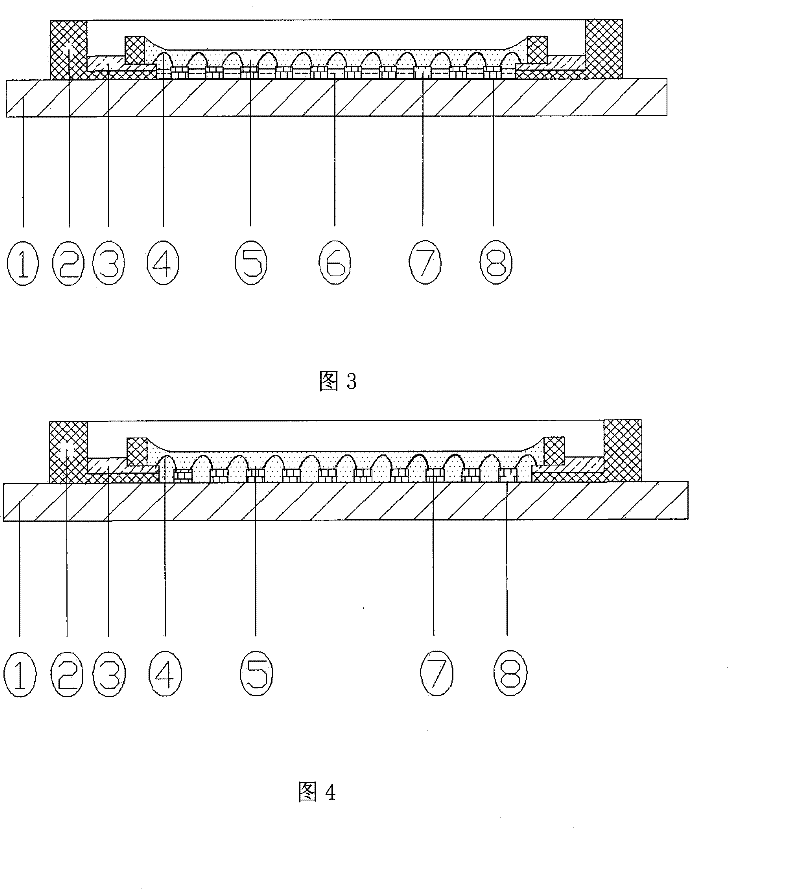

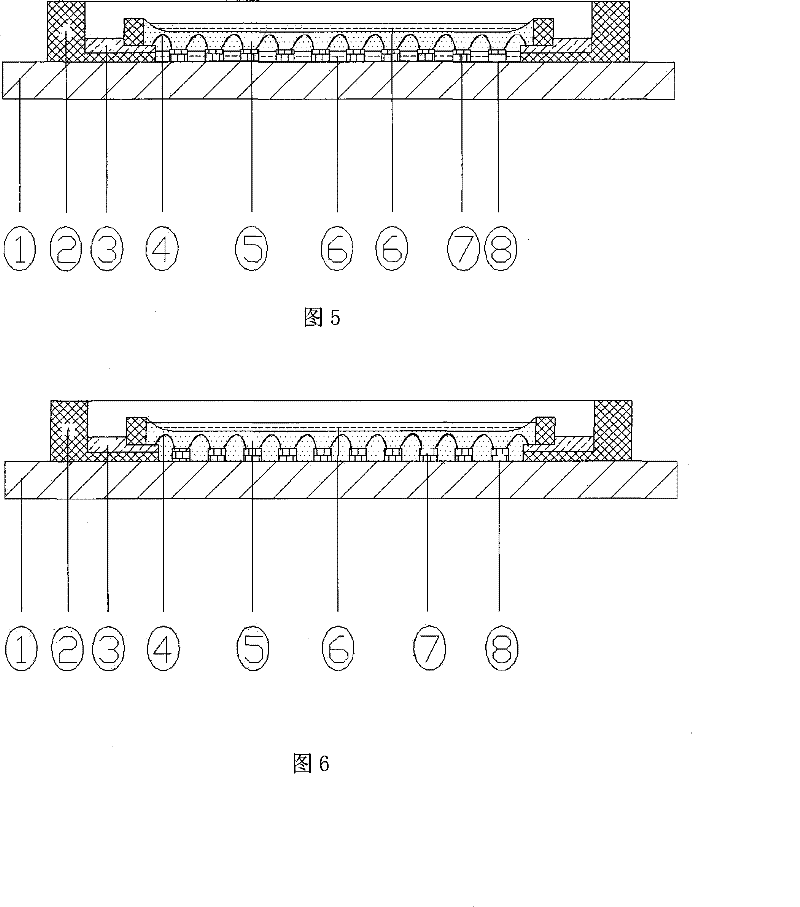

Method used

Image

Examples

Embodiment Construction

[0023] In the ultra-high-power LED module light source of the present invention, the connection between the LED chip and the bracket can be done by artificial or automatic die-bonding, and the wire can be bonded by a semi-automatic wire bonding machine or a fully automatic wire bonding machine. The production of the phosphor layer and its silica gel layer can be realized by an automatic dispensing machine in the existing high-power operation mode.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com