Cable wire connector

A technology for wires and cables and connectors, which is applied in the field of wire and cable connectors, and can solve problems such as loose connections between molded terminals and wires and cables

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

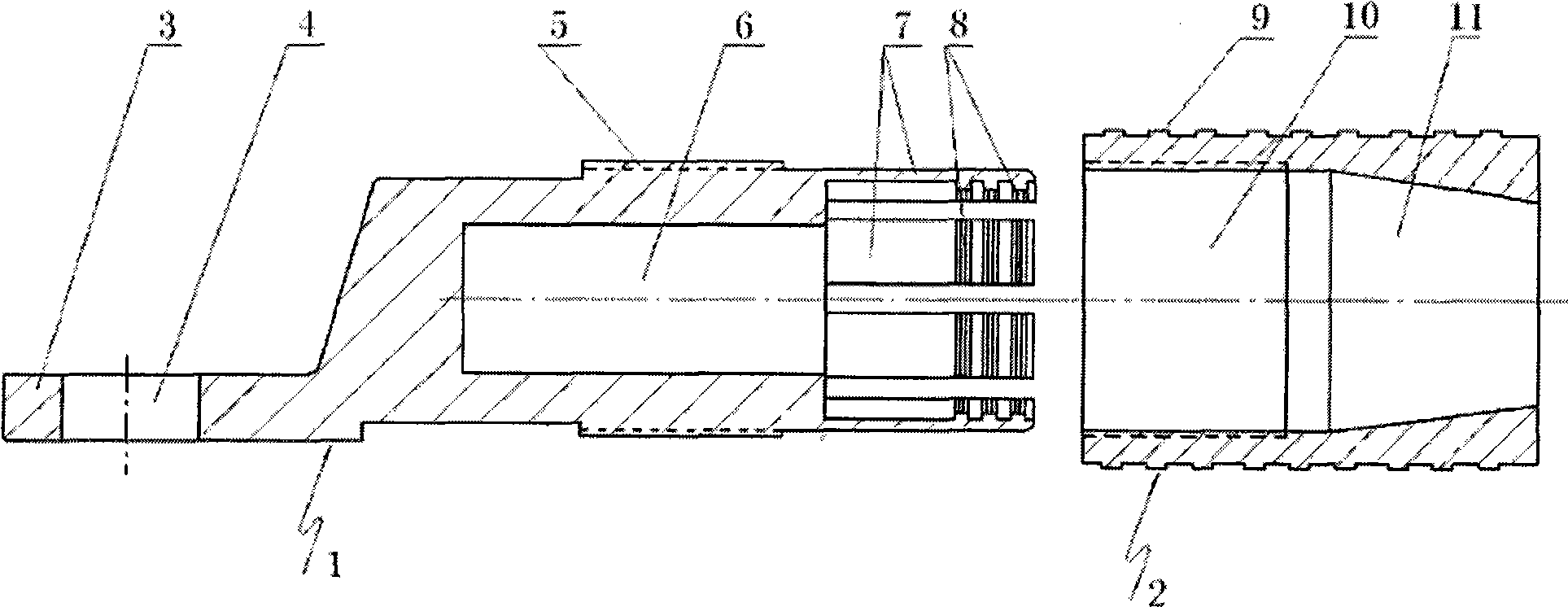

[0012] like figure 1 As shown, the wire and cable connector is composed of a connecting body 1 and a fastening cap 2. One end of the connecting body 1 is a flat end 3 with a connecting hole 4 on it. The other end of the connecting body 1 has six deformed strips 7 with gaps between each deformed strip 7, the inner wall of each deformed strip 7 has three parallel snapping blocks 8, and the middle section of the connecting body 1 has external threads 5. The connecting body has a wire and cable insertion hole 6. The fastening cap 2 has an internal thread 10 that cooperates with the external thread 5 of the connecting body 1 and an inner tapered surface 11 on the outer surface of the compression deformation strip 7, and the outer peripheral surface of the fastening cap 2 has a plurality of protruding rings 9 that increase friction .

[0013] When in use, insert the wire and cable into the wire and cable insertion hole 6 of the connecting body 1, then put the fastening cap 2 on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com