Modularized factory building structure

A modular, workshop technology, applied in industrial buildings and other directions, to achieve the effect of increasing comfort, convenient transportation, and reducing walking distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

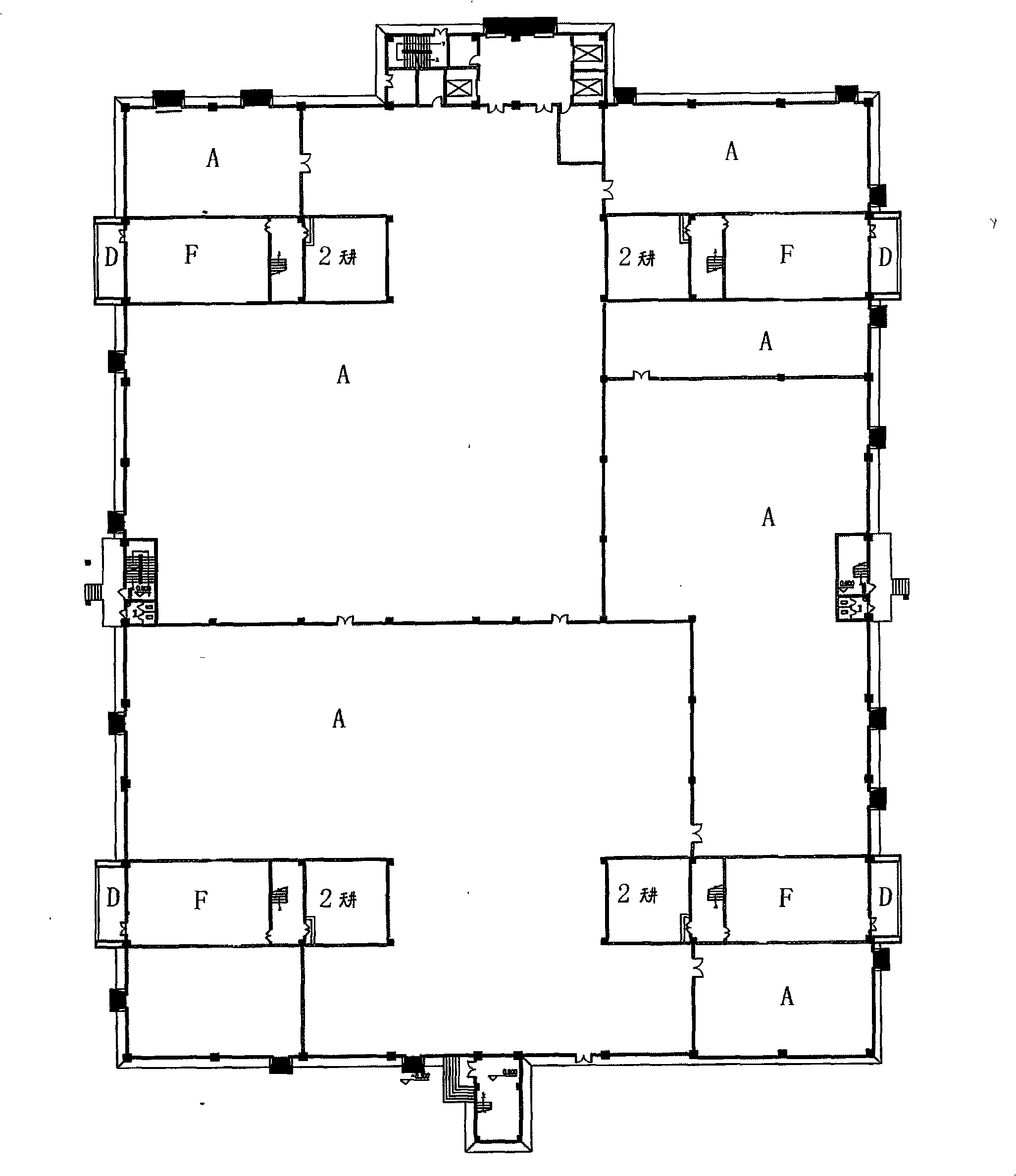

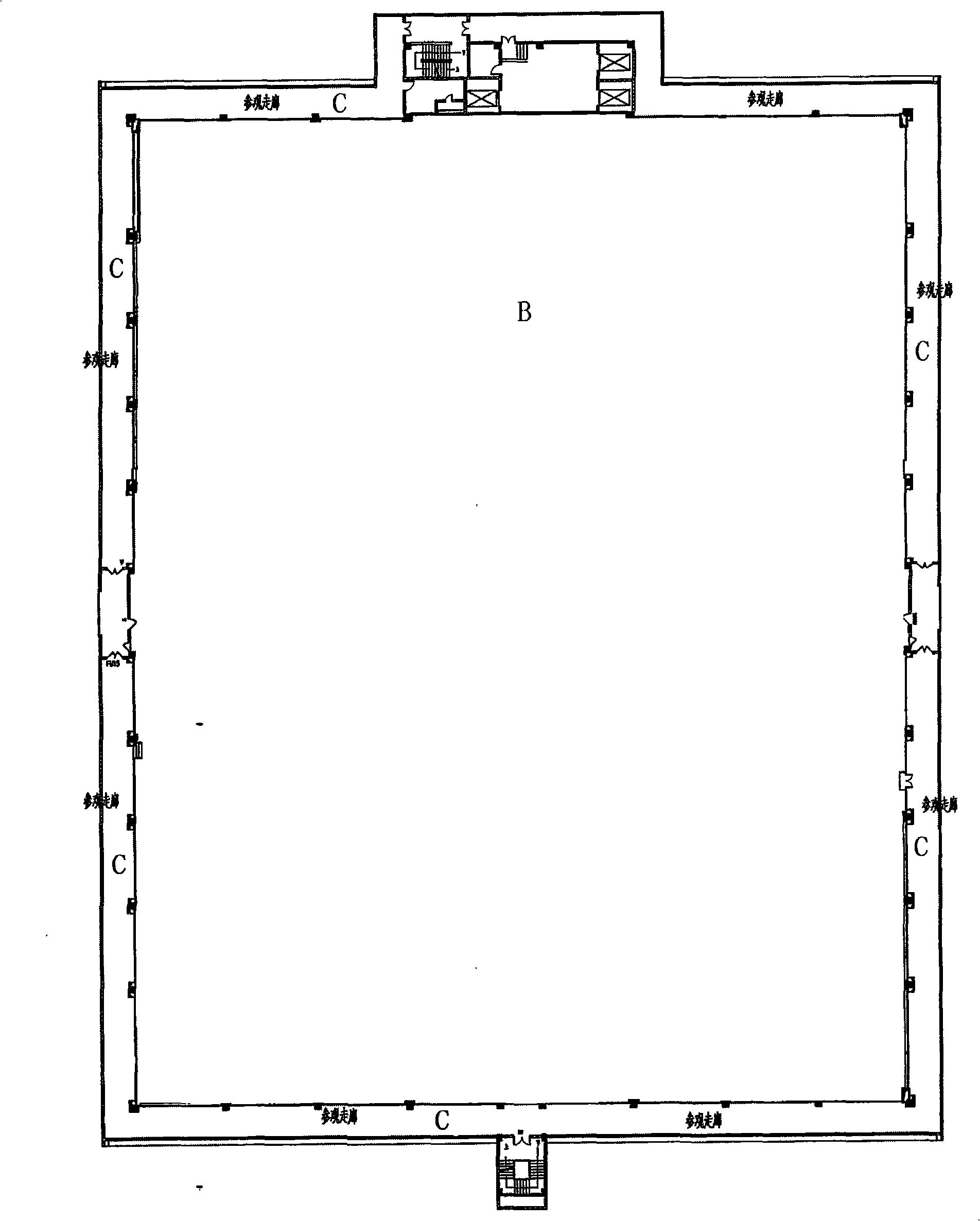

[0025] A modular factory building structure, the factory building is composed of 2 floors, the height of each floor is 5 meters, the first floor is the comprehensive area A, the second floor is the production operation area B and the viewing corridor C around the production operation area B , the production operation area B is composed of a modular production area 3, there is no direct connecting channel between the modular production area 3 and the visiting corridor C surrounding the production operating area, and they are independent of each other, the ground of the visiting corridor C is higher than that of the production operating area The ground is 0.4 meters. A patio 2 is set in the modular production area 3, the entrance D of the modular production area 3 is located in the comprehensive area A on the first floor, and the changing room and shower room are located in the mezzanine F on the first floor of the first floor, and the mezzanine F is in the modular production are...

Embodiment 2

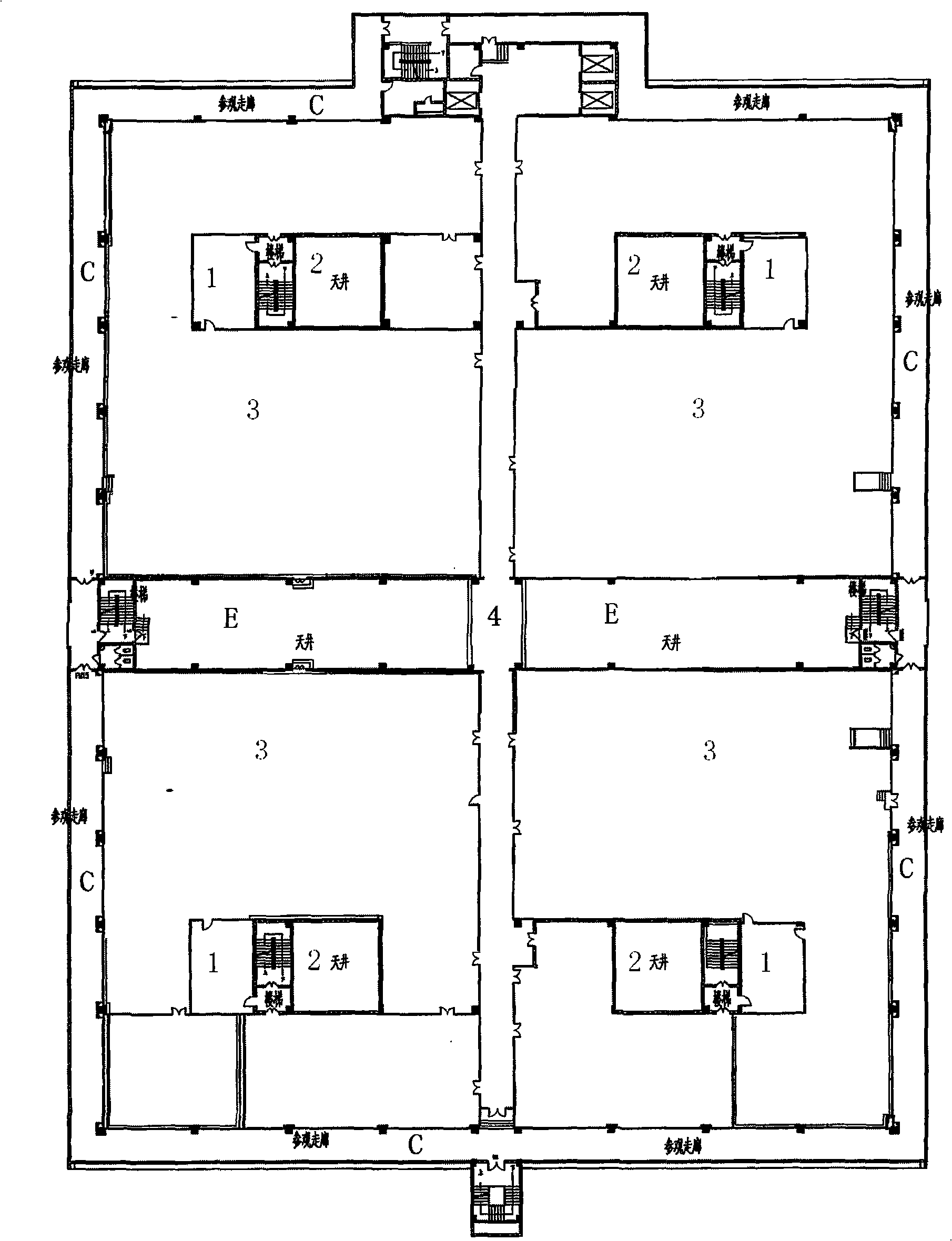

[0027] A modular factory building structure, the factory building is composed of 3 floors, the height of each floor is 6 meters, the first floor is the comprehensive area A, the second and third floors are the production operation area B and the visiting corridor C around the production operation area B The production operation area B is composed of three modular production areas 3. There is no direct connecting passage between the modular production area 3 and the viewing corridor C surrounding the production operation area, and they are independent of each other. The ground of the viewing corridor C is higher than the production area. The ground of the operating area is 0.5 meters, and the first floor mezzanine F is located at a structural mezzanine between the height of 3 meters from the ground to the top of the first floor, and all the other are the same as embodiment 1.

Embodiment 3

[0029] In the modular factory building structure of the present invention, the factory building is made of 10 floors, and the floor height of each floor is 7 meters. A patio E is arranged in the middle of the production operation area B on each floor, and the modular production area 3 is separated on two sides of the patio E. On the side, a connecting channel 4 is set in the middle of the patio E, and stairs are respectively set at both ends of the patio. All the other are with embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com