Door handle

A door handle and operating handle technology, applied in the field of door handles, can solve the problems of poor appearance, difficult operability, easy to be stained with dust, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

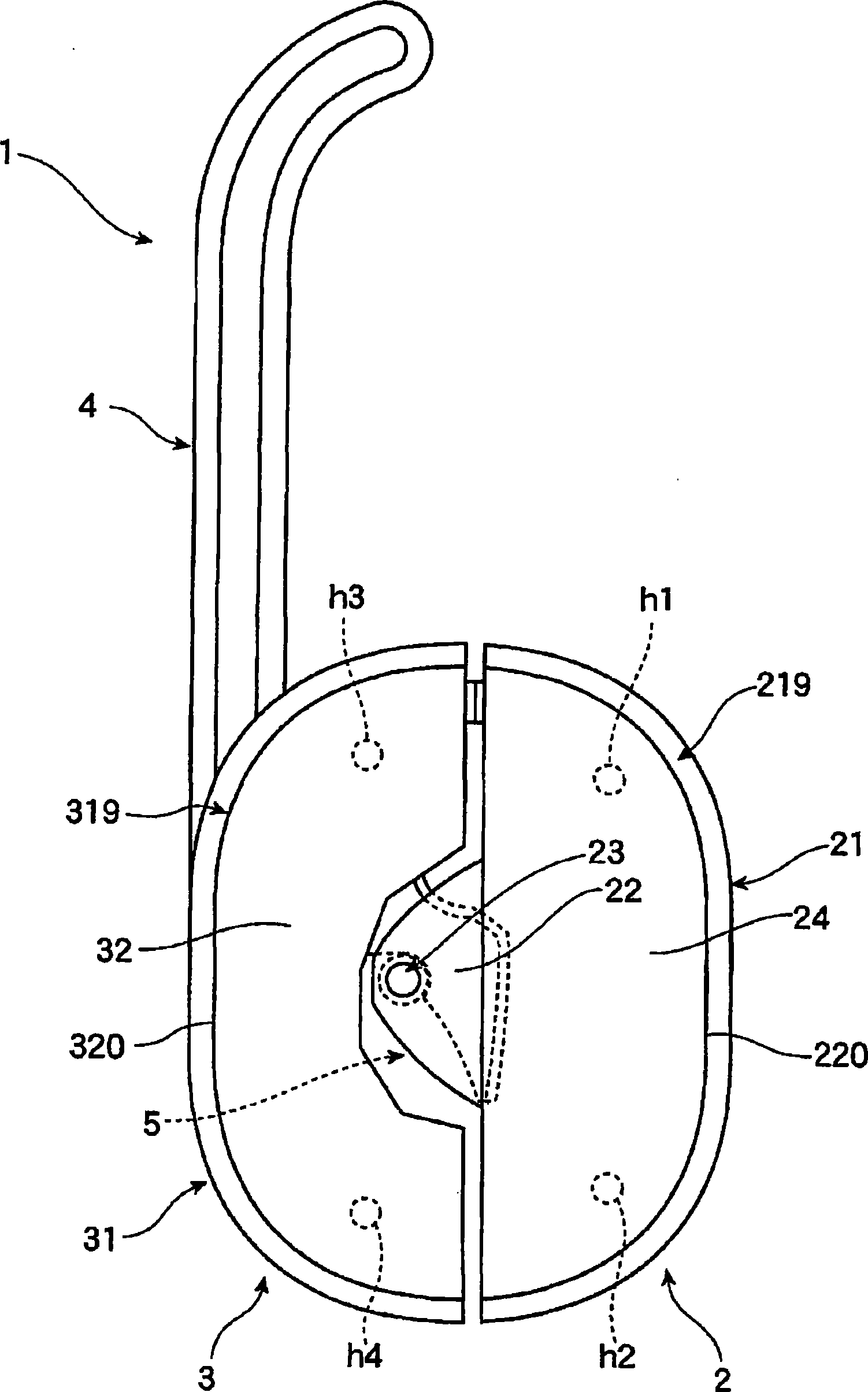

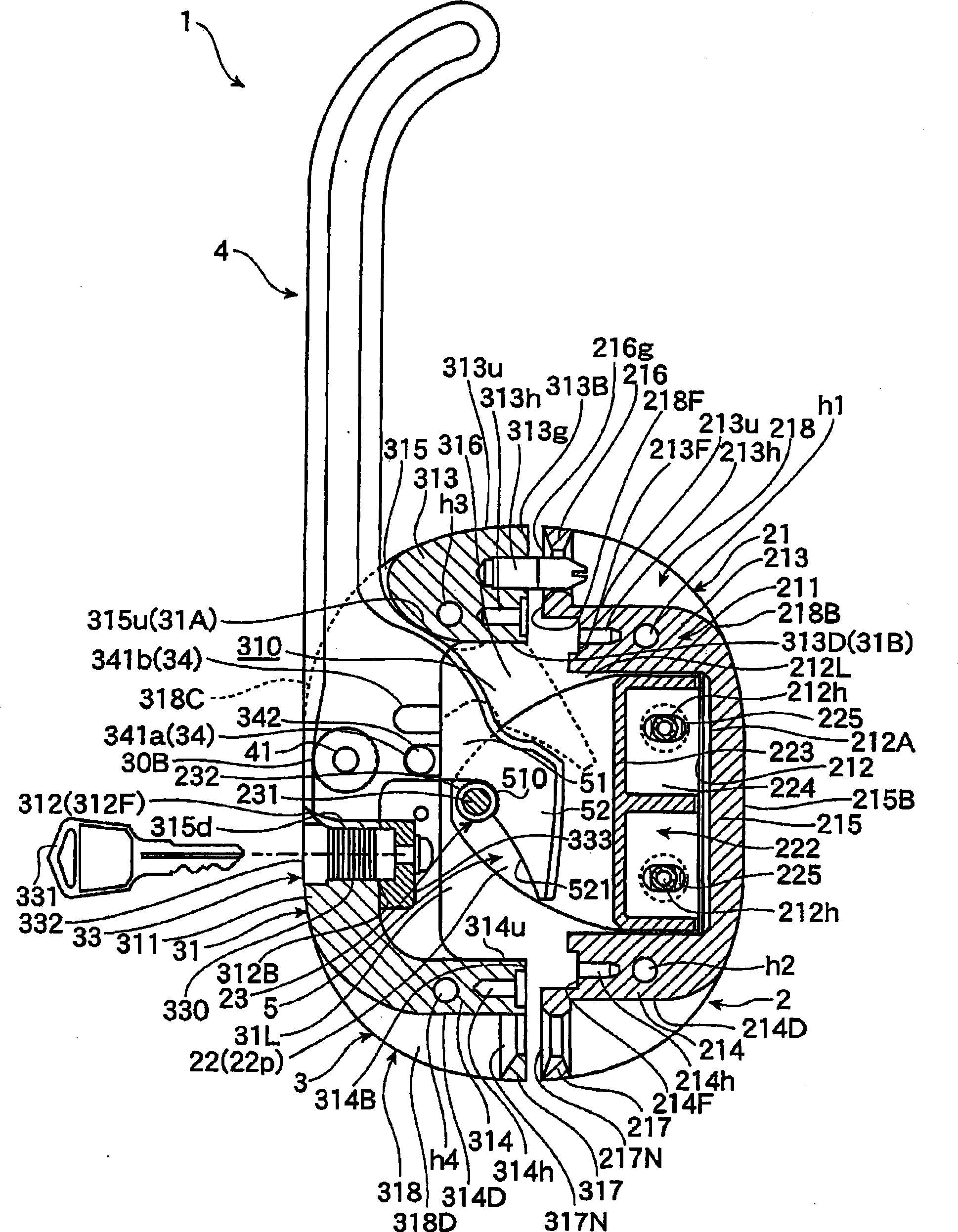

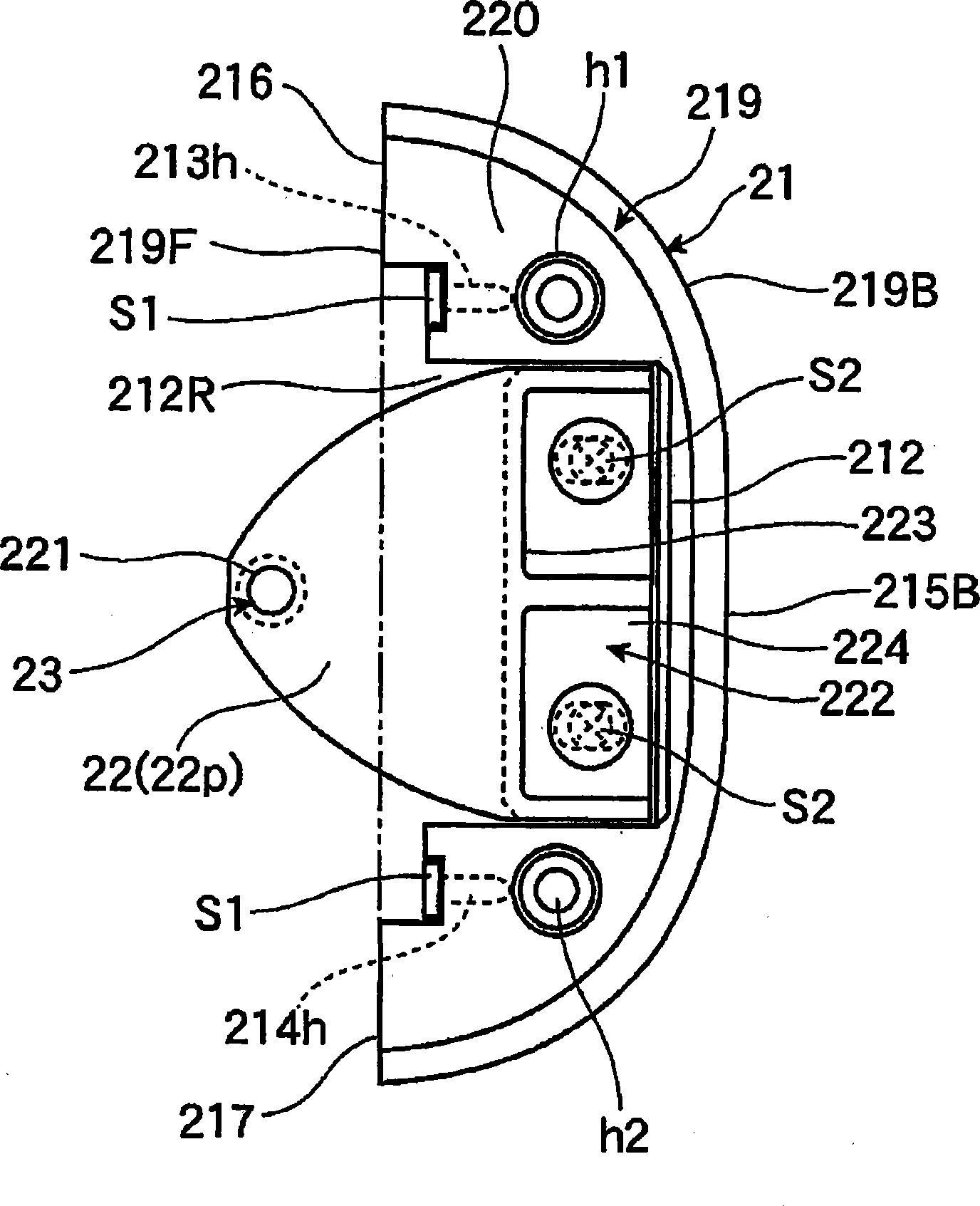

[0135] Hereinafter, an embodiment of the present invention will be described with reference to the accompanying drawings. figure 1 Partially broken side view for the door handle, figure 2 It is a side sectional view of the door handle. image 3 For the right side view of the door handle especially the bracket, Figure 4 is the front view of the bracket. Figure 5 It is the front view of the door handle, especially the fixed base and the operating handle, Image 6 Partially broken back view of the fixed base, the operating handle and the locking lever.

[0136] like figure 1 and figure 2 As shown, the door handle 1 includes a bracket 2 fixedly connected to the fixed frame body, an operating handle 4 and a locking lever 5 fixedly connected to the door and then installed through the fixed base 3 .

[0137] like figure 1 , figure 2 and image 3 As shown, the bracket 2 has: a mounting base 21; a pair of handles 22, 22 provided on the mounting base 21 protruding forward; a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com