Injection die capable of precise electronic product subtilis connector plastic shell

A technology of precision electronics and injection molds, applied in household appliances, other household appliances, household components, etc., can solve the problems of increasing mold manufacturing costs, affecting production continuity, reducing production efficiency, etc., to reduce the frequency of replacing parts and avoid grinding. Sassafras deformation, the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with accompanying drawing.

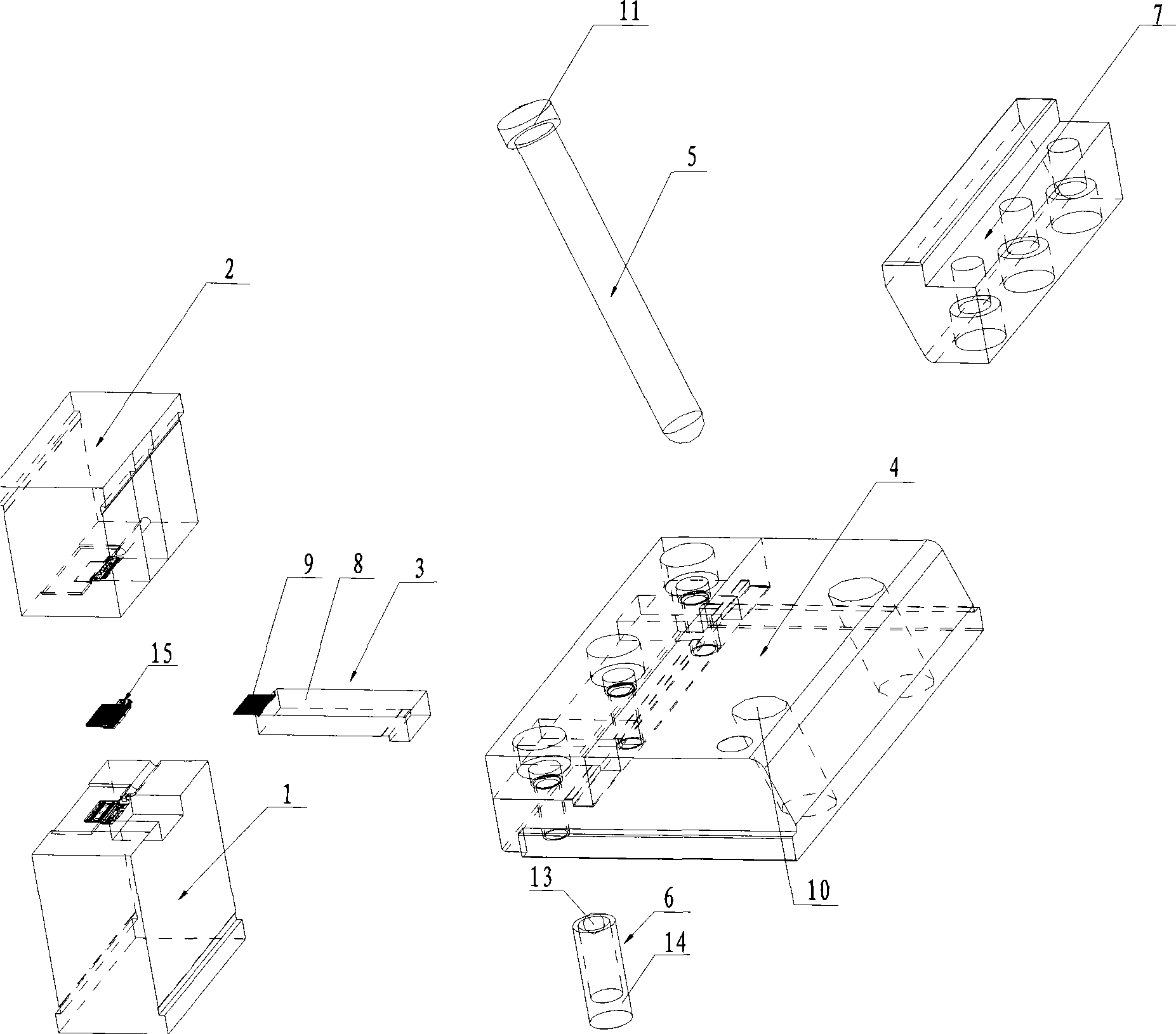

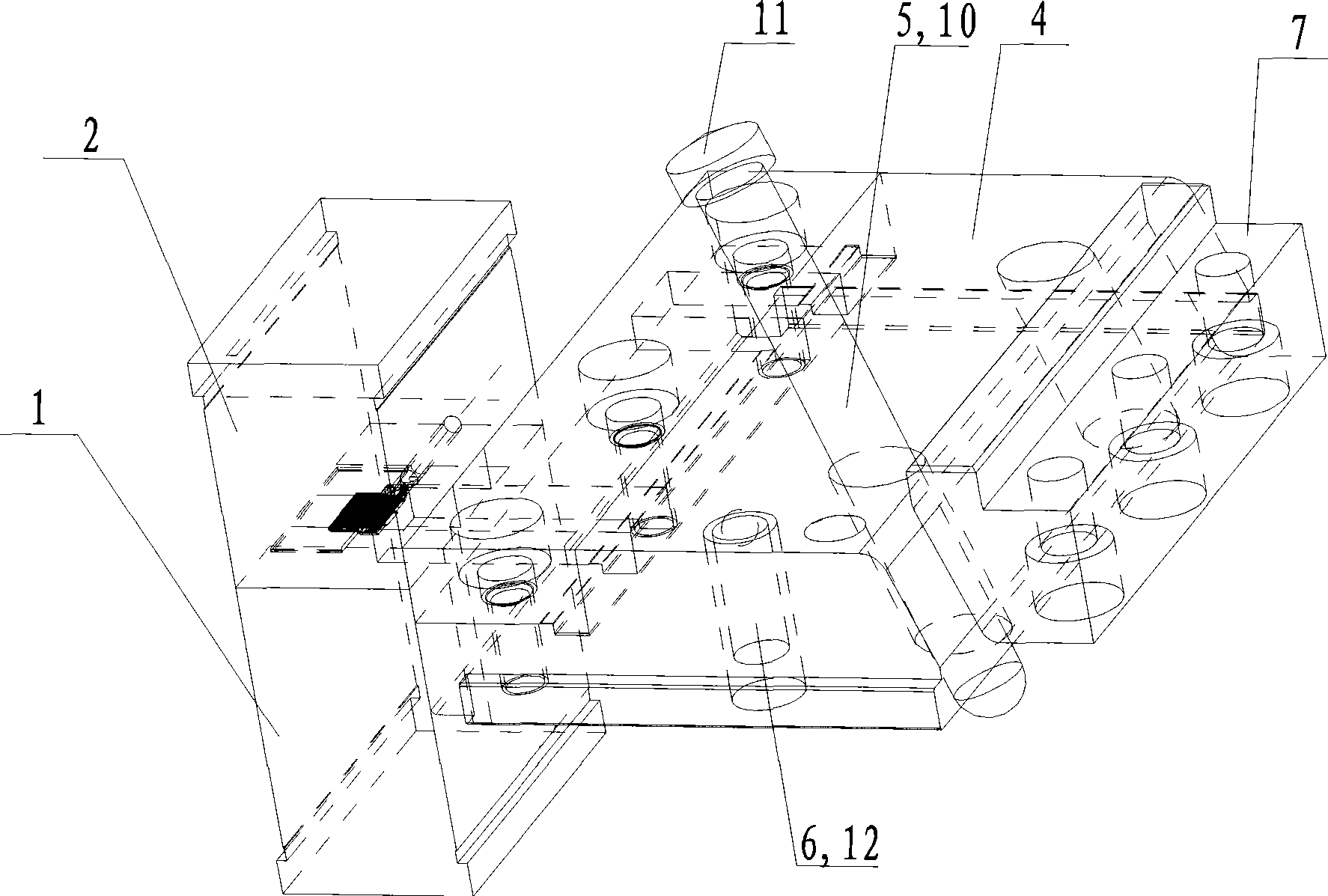

[0012] Such as figure 1 , 2 As shown, the injection mold for producing the small connector plastic case of precision electronic products includes a male mold 1, a female mold 2, a protection piece 3, a slider 4, an inclined guide post 5, an elastic reset piece 6, and a slider locking piece 7. The protective piece 3 includes a fixed handle 8 and a protective sheet 9, the protective sheet 9 is fixed on the front end of the fixed handle 8, and the front side of the slider 4 is provided with a groove matching the fixed handle, The fixed handle 8 is fixed in the groove, and the slider 4 is provided with at least one inclined hole 10 passing through the top surface and the bottom surface, and the inclined guide post 5 is arranged in the inclined hole 10, and the inclined guide post 5 Each head end is provided with a cylindrical handle 11, and the bottom surface of the slider 4 ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap