Tunnel ahead support stent

A technology of advanced support and roadway, which is applied to mine roof supports, mining equipment, earthwork drilling, etc., can solve problems such as poor adaptability, and achieve the effect of strong adaptability and improved support conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

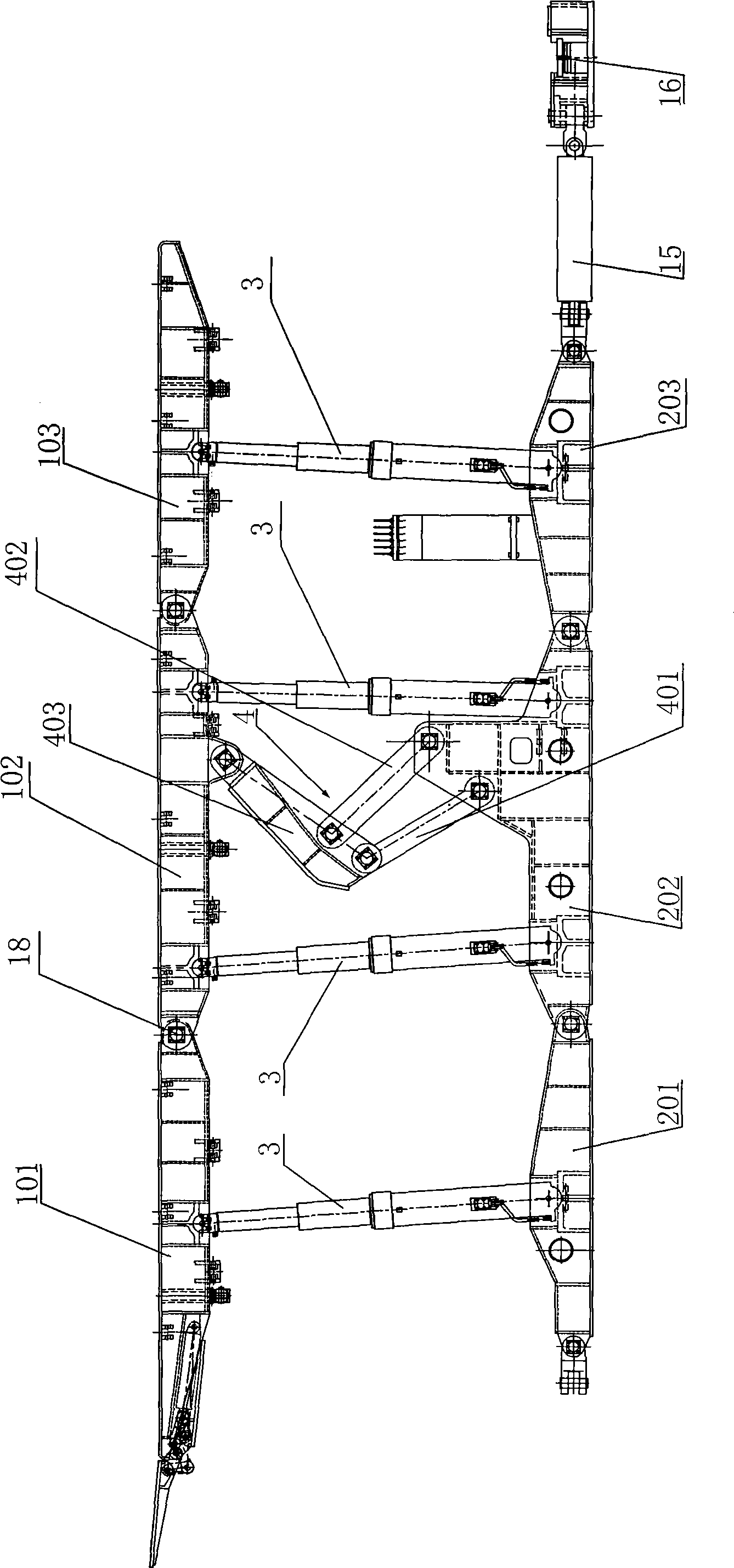

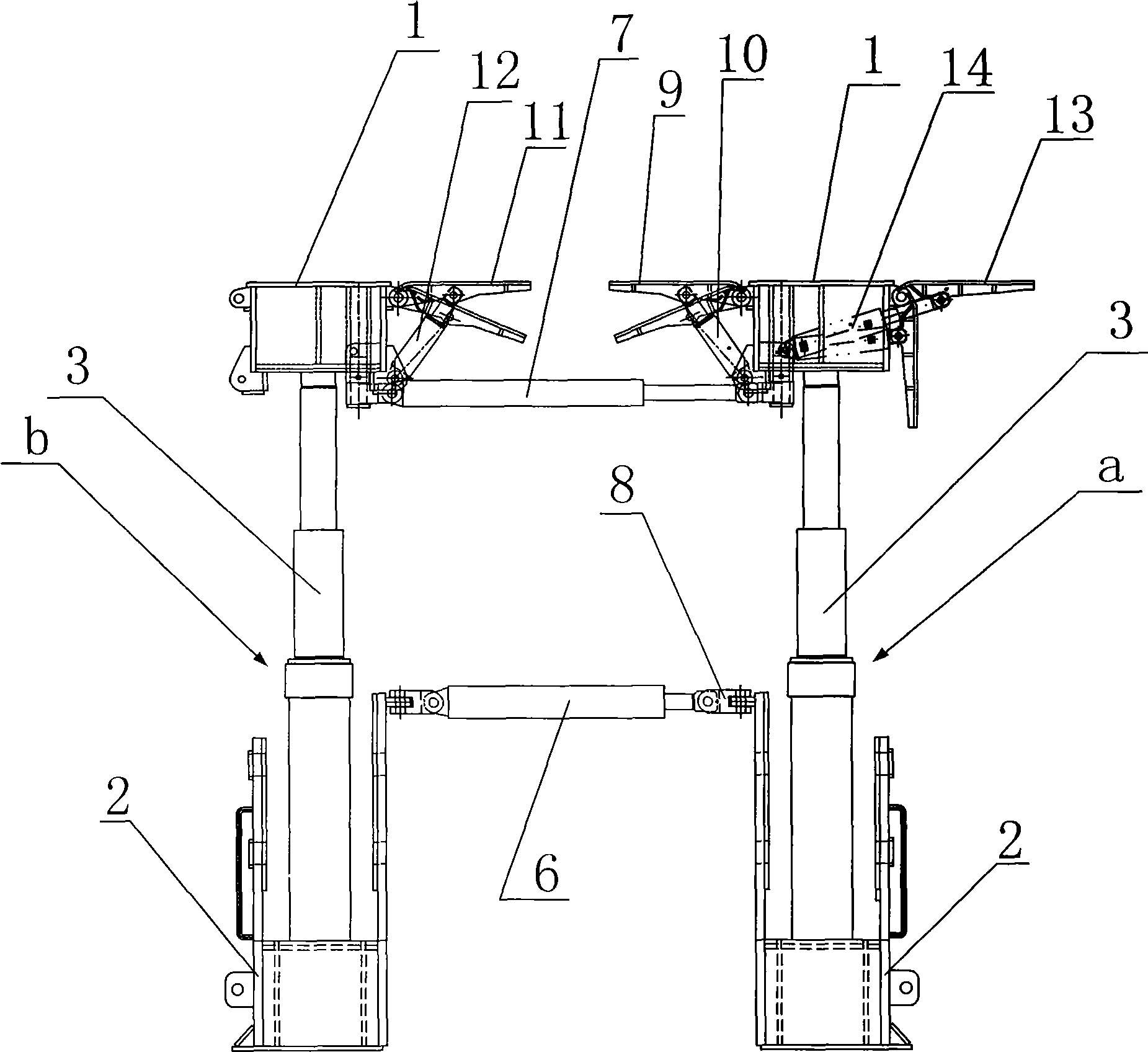

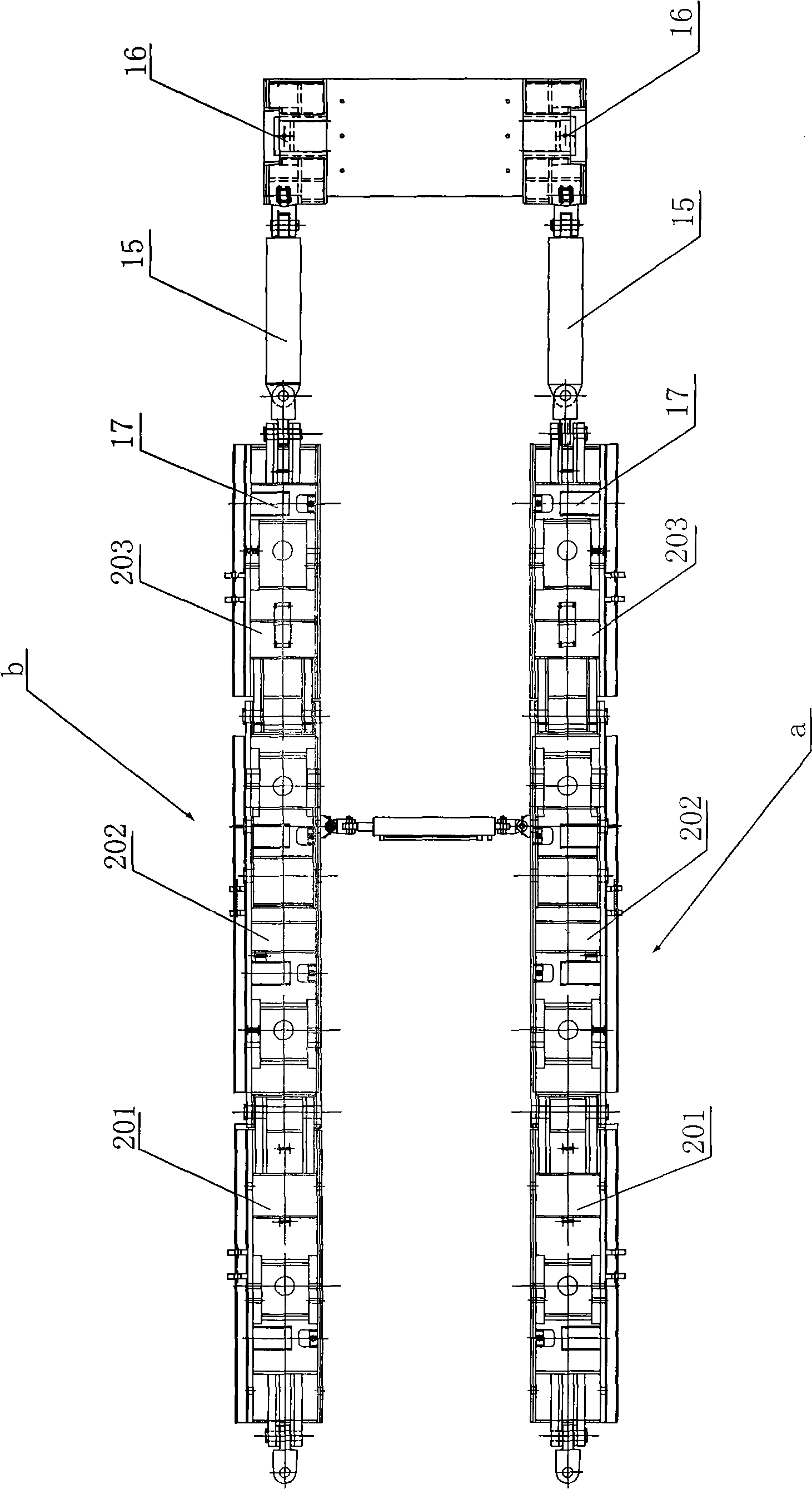

[0020] combine figure 1 , figure 2 and image 3 , a roadway advance support bracket, including a main frame body a and a sub-frame body b, the main frame body and the sub-frame body a, b each include a top beam 1 and a base 2, and a telescopic support is provided between the top beam 1 and the base 2 Column 3 and supporting four-bar linkage mechanism 4, the rear end of base 2 is provided with moving jack 5, and the moving jack 5 is connected with moving seat 15 by crosshead 16. The main and sub-frames a and b are side by side to form a group, and the main and sub-frames a and b are connected by the anti-fall jacks 6 and 7 through the connector 8, that is, between the bases of the above-mentioned main frame and the sub-frame Bottom anti-fall jacks 6 are provided, and top anti-fall jacks 7 are arranged between the top beams. Taking the main frame body a as an example, its top beam 1 is composed of front, middle and rear beams, that is, the front beam 101, the middle beam 102...

Embodiment 2

[0024] Except that no inner guard plate (outer guard plate) is set on the top beam of the above-mentioned main frame body and sub-frame body, and the base of the main frame body and sub-frame body does not adopt fixed seat body and movable seat plate, and correspondingly adjust the jack, Other technical contents are the same as those of the corresponding part of Embodiment 1.

Embodiment 3

[0026] Except that the top beam and the base of the main (auxiliary) frame body are composed of two sections of hinged joints, other technical contents are the same as those in the corresponding parts of Embodiment 1 or Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com