An in-situ reinforcement method for "U-shaped steel bracket"

A type of steel, in-situ technology, applied in the field of in-situ reinforcement of U-shaped steel brackets, can solve the problems of U-shaped steel bracket replacement construction difficulties, small underground roadway space, and increased support costs, so as to save economic costs, improve overall rigidity and The effect of strength and support performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0022] The present invention provides a "U-shaped steel bracket" in-situ reinforcement method. In order to make the purpose, technical solution and effect of the invention more clear and definite, the schematic diagram of this invention is used below to further describe its implementation in detail. It should be understood that the illustrations of the invention described here are only used to explain the invention, not to limit the invention. The specific implementation is as follows:

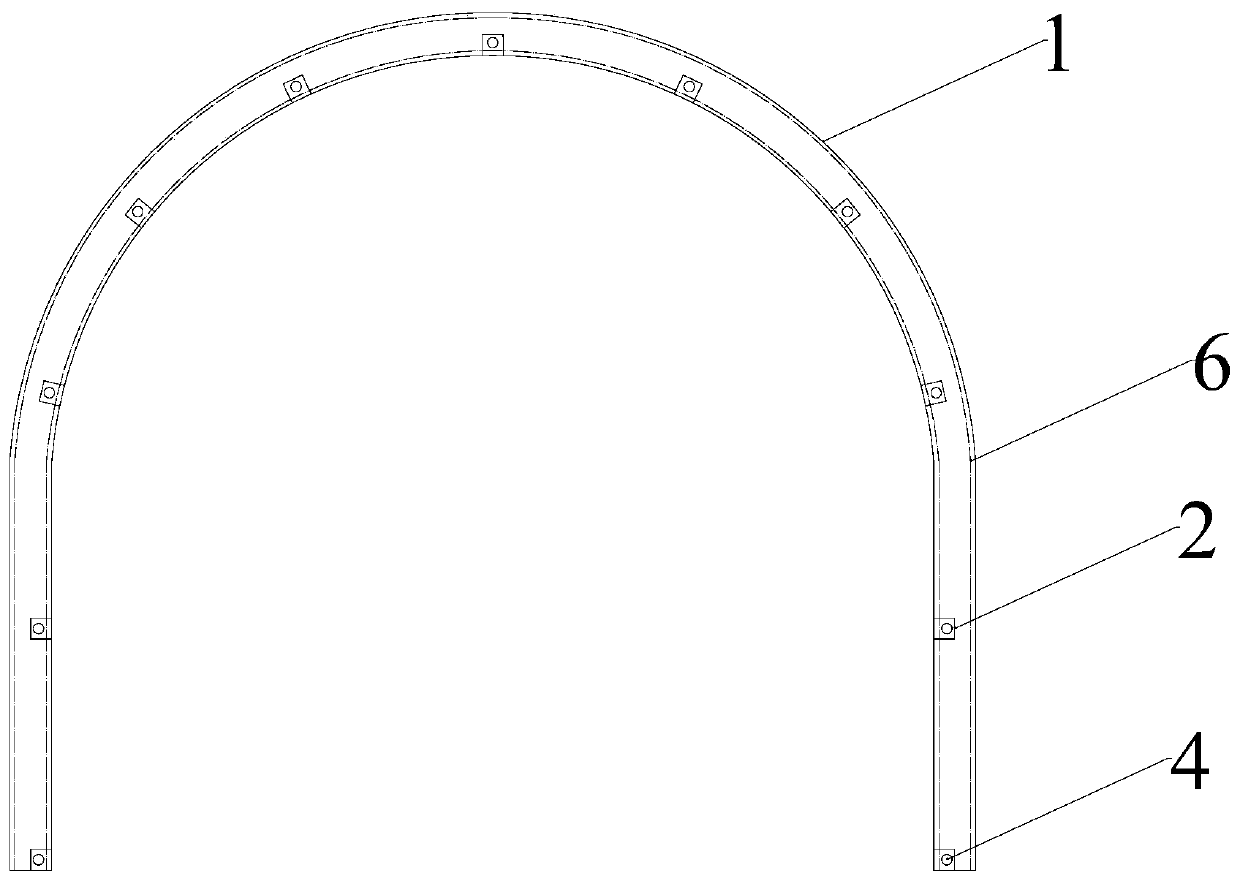

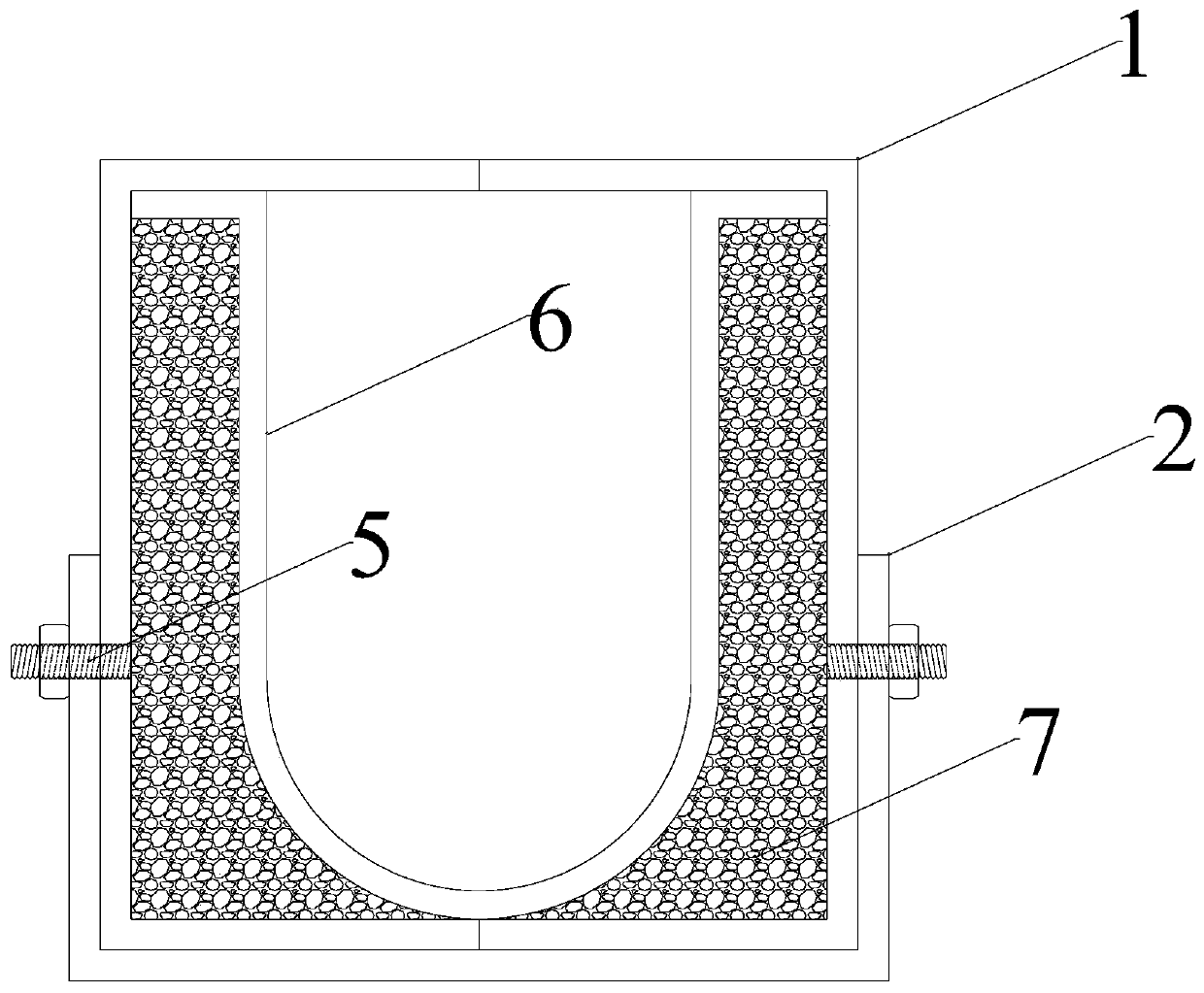

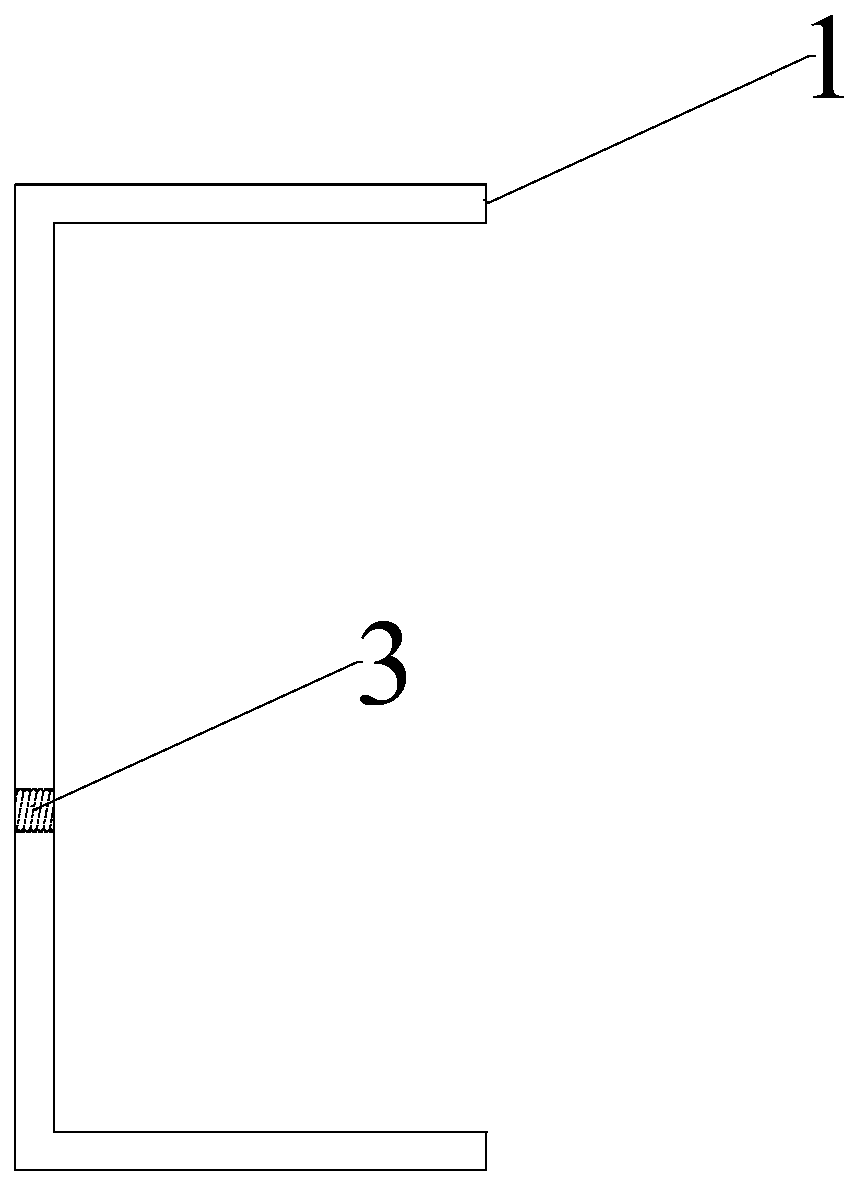

[0023] An in-situ reinforcement method for a "U-shaped steel bracket" is divided into the following steps: the U-shaped steel bracket (6) to be reinforced remains stationary, and two "["-shaped reinforcement devices ( 1), inject concrete (7) from the bolt hole (3) of the "["-shaped reinforcement device (1) to the gap formed between the "["-shaped reinforcement device (1) and the U-shaped steel bracket (6), and finally use the bolt ( 5) and "凵" shaped fixing device (2) fix two "[" shaped reinf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com