Method for keeping activity of probiotic

A probiotics, vitality technology, applied in the direction of fixed on/in organic carrier, animal feed, animal feed, etc., can solve the problems of probiotics loss of vitality, loss of efficacy, inability to use heat-sensitive microbial products, etc., to reduce Activity, improve utilization, improve the effect of ecological environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] Embodiment 1 (taking lactobacillus as example)

[0014] Every gram of cornstarch uses 100 micrograms of α-amylase to prepare microporous starch (preparation method with prior art), the reaction time is 12 hours, the reaction temperature is 55 ° C, and the reaction pH is 6.0. Under this condition, better Microporous starch (pore size is about 1 μm. The ratio of the cavity volume of microporous starch to the total volume of starch is greater than 50%), and 100 g of this microporous starch is used to adsorb (also call embedding) 50 g of lactic acid bacteria in its cavity Inside.

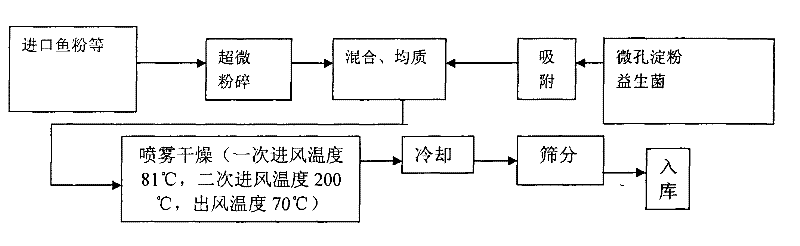

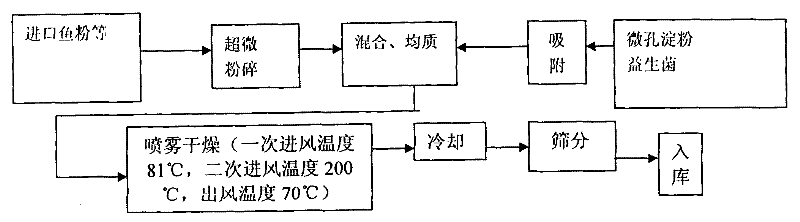

[0015] Then use the above-mentioned substances plus the total weight of 100kg of nutrients required by aquatic seedlings (finely crushed particle size less than 0.046μm) as the core material, and use 1kg of chitosan dissolved in 400ml of lactic acid and 40kg of aqueous solution as the wall material to make microcapsules. The most commonly used method for making microcapsules is the spray drying ...

Embodiment 2

[0016] Embodiment 2 (taking lactobacillus as example)

[0017] Every gram of cornstarch uses 100 micrograms of α-amylase to prepare microporous starch (using prior art), the reaction time is 12H, the reaction temperature is 55°C, and the reaction pH is 6.0. Under this condition, better microporous starch can be prepared (The microporous size is about 1 μm. The ratio of the cavity volume of the microporous starch to the total starch volume is greater than 50%). Use this microporous starch 100g to adsorb (also claim to embed) 55g lactobacillus in its cavity.

[0018] Then use the above-mentioned substances plus the total weight of 100kg of nutrients required by aquatic seedlings (finely crushed particle size less than 0.046μm) as the core material, and use 1kg of chitosan dissolved in 400ml of lactic acid and 40kg of aqueous solution as the wall material to make microcapsules. The most commonly used method for making microcapsules is the spray drying method. The temperature of t...

Embodiment 3

[0019] Embodiment 3 (taking lactobacillus as example)

[0020] Every gram of cornstarch uses 100 micrograms of α-amylase to prepare microporous starch (using prior art), the reaction time is 12H, the reaction temperature is 55°C, and the reaction pH is 6.0. Under this condition, better microporous starch can be prepared (The microporous size is about 1 μm. The ratio of the cavity volume of the microporous starch to the total starch volume is greater than 50%). Use this microporous starch 100g to adsorb (also claim to embed) 60g of lactobacilli in its cavity.

[0021] Then use the above-mentioned substances plus the total weight of 100kg of nutrients required by aquatic seedlings (finely crushed particle size less than 0.046μm) as the core material, and use 1kg of chitosan dissolved in 400ml of lactic acid and 40kg of aqueous solution as the wall material to make microcapsules. The most commonly used method for making microcapsules is the spray drying method. The temperature of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com