Light-wave cooker

A light-wave oven and light-wave heating technology, used in kitchen utensils, home utensils, roasters/barbecue grids, etc., can solve the problems of space for transportation and storage, the large volume of food heating chambers, and the unavailability of space in food heating chambers. , to solve the space problem of transportation and storage, and to increase the scope of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

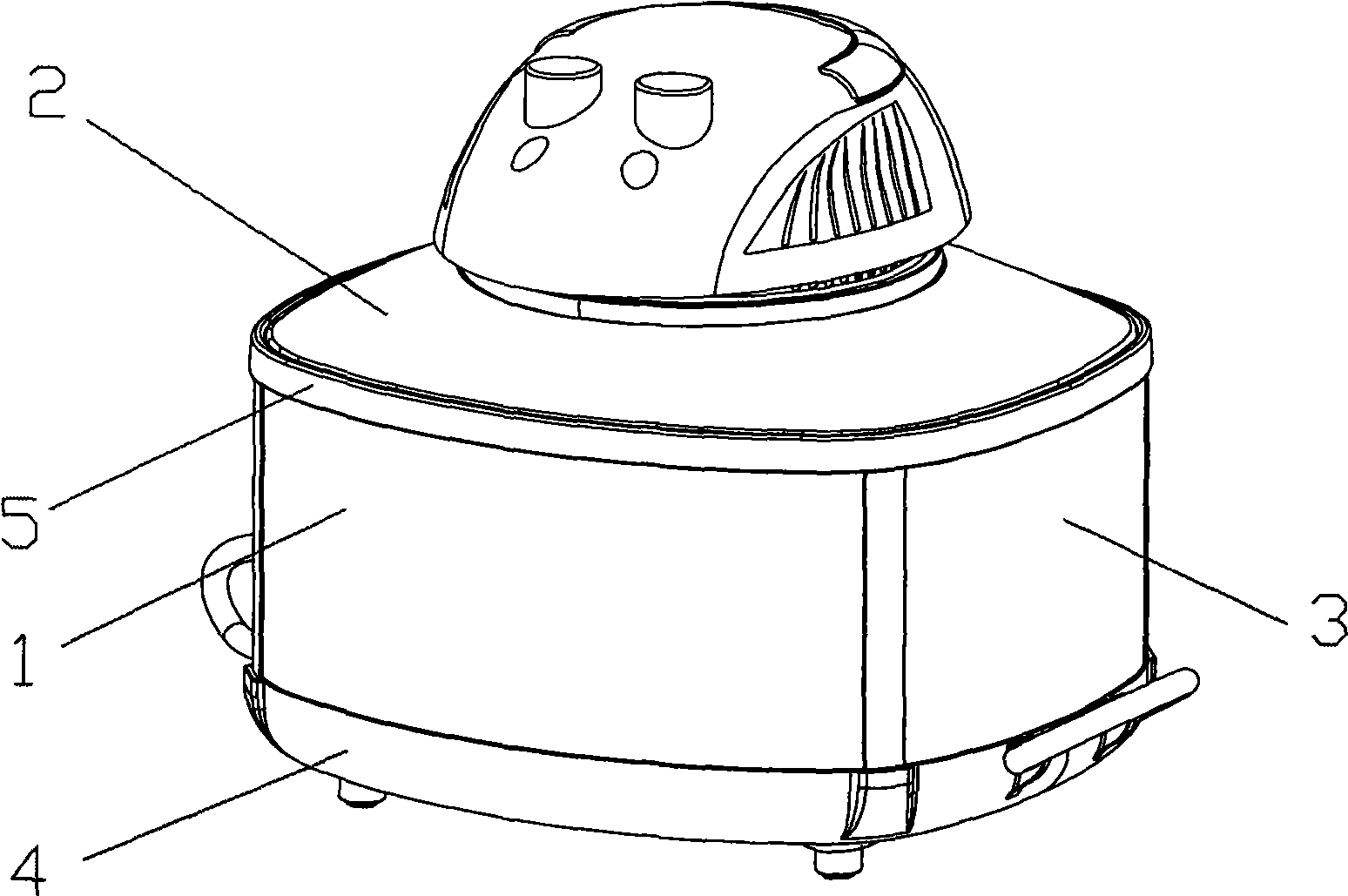

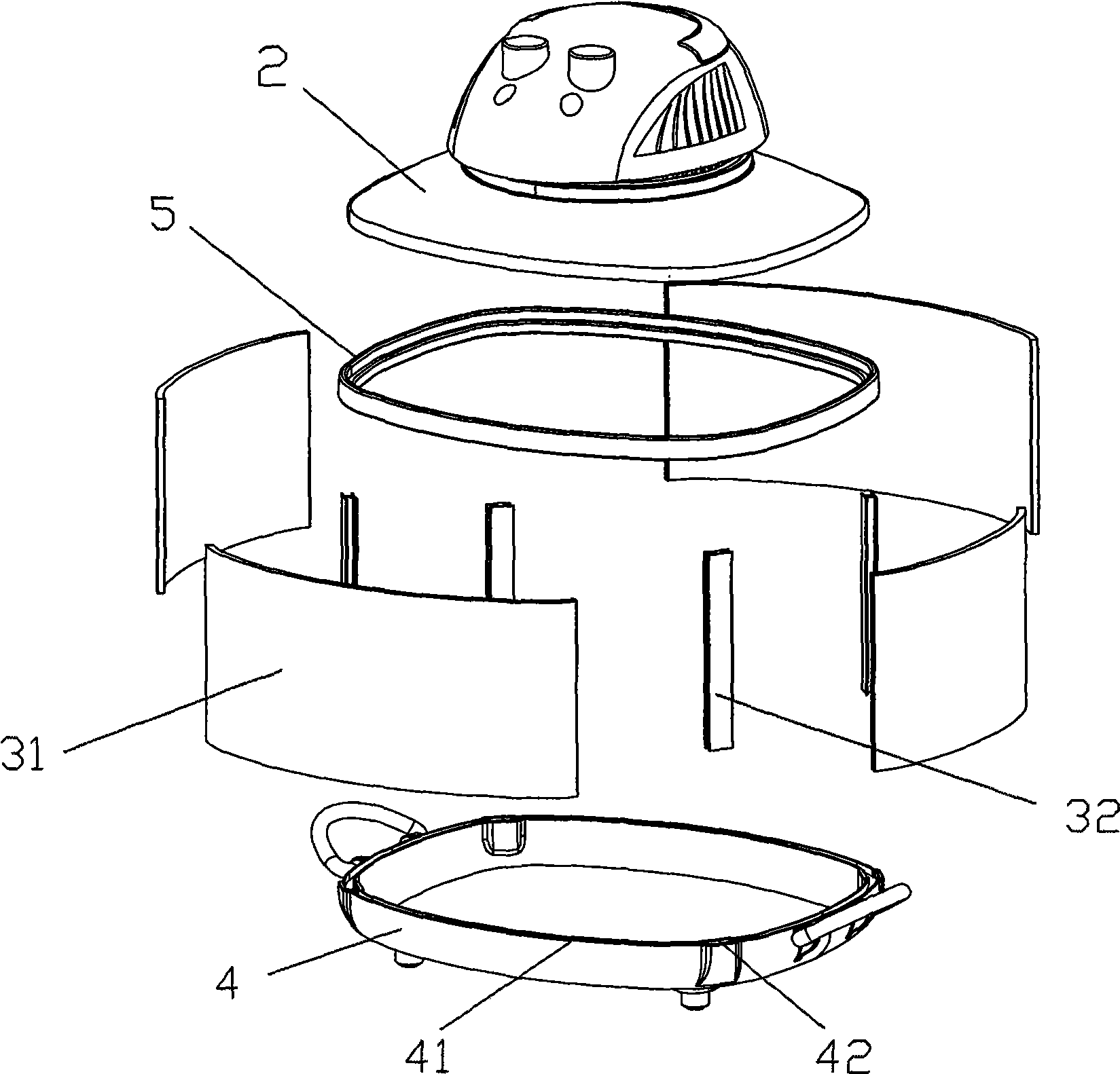

[0012] refer to figure 1 , figure 2 , a light-wave oven, which includes a food heating cavity 1, the top of the food heating cavity 1 is provided with a cover 2 with a light wave heating device, the food heating cavity 1 is divided into a glass side plate 3 and a chassis 4 for receiving food, the The glass side panel 3 described above is spliced by a plurality of glass plates 31 and connecting columns 32. The connecting columns 32 are I-shaped, and the chassis 4 is provided with slots 41 for inserting the glass plates 31 and the connecting columns 32. , 42.

[0013] In order to ensure the installation strength of this product, a reinforcing ring 5 is provided on the top of the food heating chamber 1 .

[0014] This product divides the original one-piece food heating chamber 1 into several parts that can be disassembled, thus effectively solving the space problem of transportation and storage. In addition, according to actual needs, the chassis 4 can be disassembled and us...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com