Tool for connecting contact wires

A catenary and wire technology, applied in the direction of overhead lines, etc., can solve problems such as hidden safety hazards, insufficient standard installation, and impact on travel time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

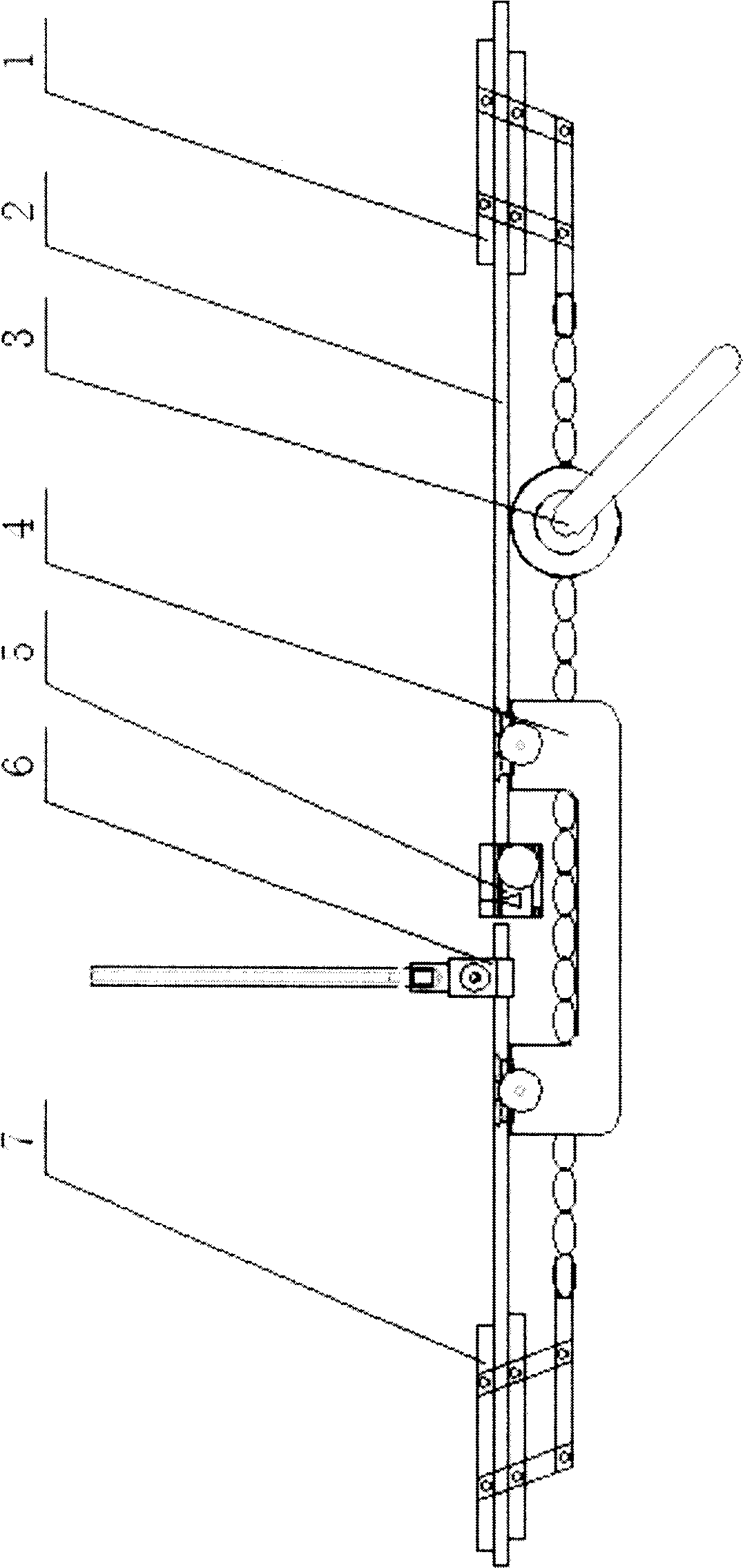

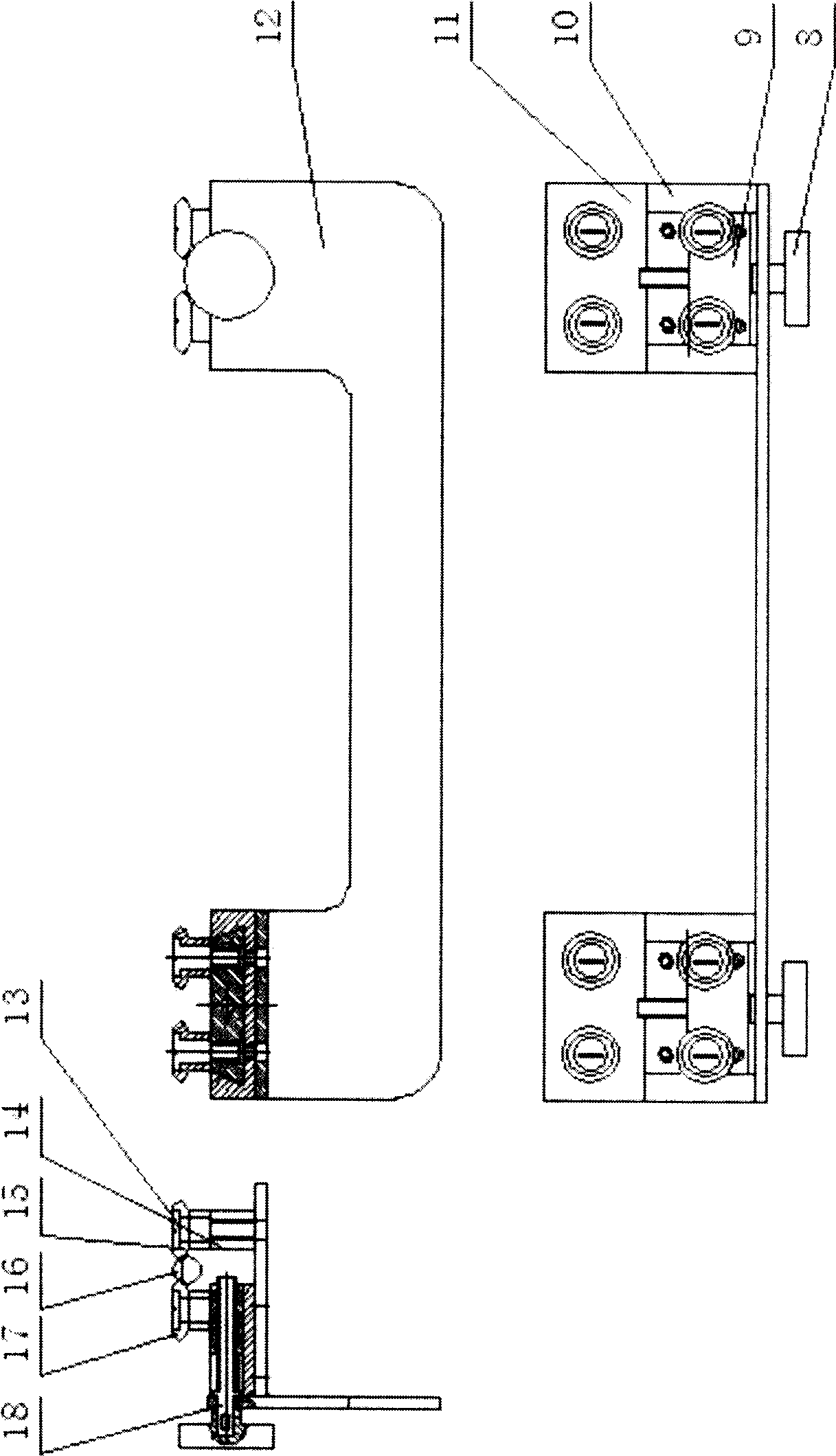

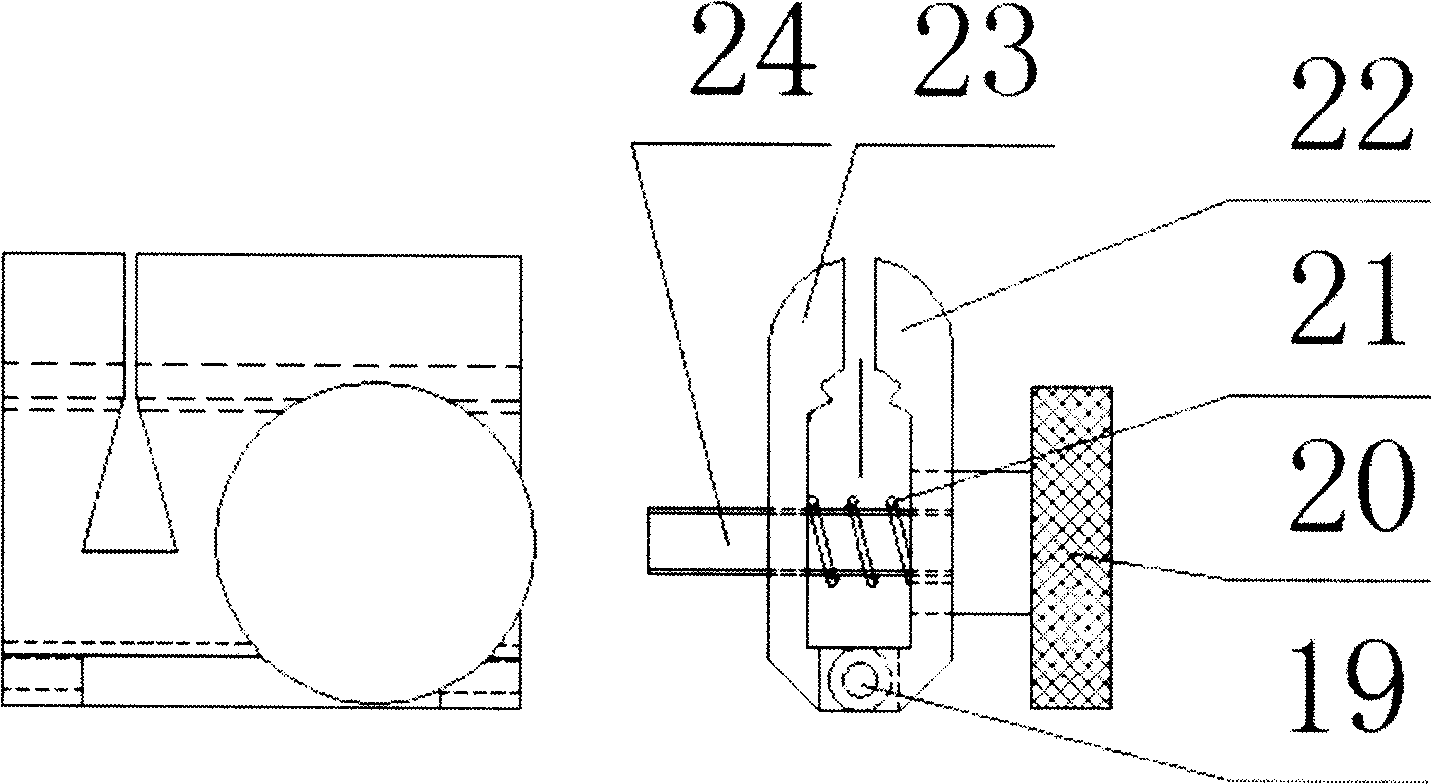

[0013] Depend on figure 1 It can be seen that the two wires to be connected are clamped by the wire clamp (1) and the wire clamp (7), and connected to the hand hoist (3), when the two wires are tightened to the In proper position and tension, according to figure 1 Install the connector (4) as shown to form a fixed operating area with adjustable distance between the stable anti-twist surface, which is composed of figure 2 It can be seen that the connector (4) can drive the screw (18) to rotate by rotating the hand wheel (8), pushing the slider (9) to move horizontally in the dovetail block (10), and the dovetail block (10) passes through the bolt and the bracket (11) connection, the bracket (11) and the U-shaped bracket (12) are welded and fixed, and the slider (9) drives the rotating positioning wheel (17) installed on it to do horizontal displacement and clamp the contact net to the rotating positioning wheel (15). wire. The profile of positioning wheel (17,15) is the sam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com