Roll changing device with wedge adjusting device

A wedge adjustment and equipment technology, which is applied in metal processing equipment, manufacturing tools, metal rolling, etc., can solve the problem of not allowing work rolls, etc., and achieve the effect of reducing the structure height and structure width

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

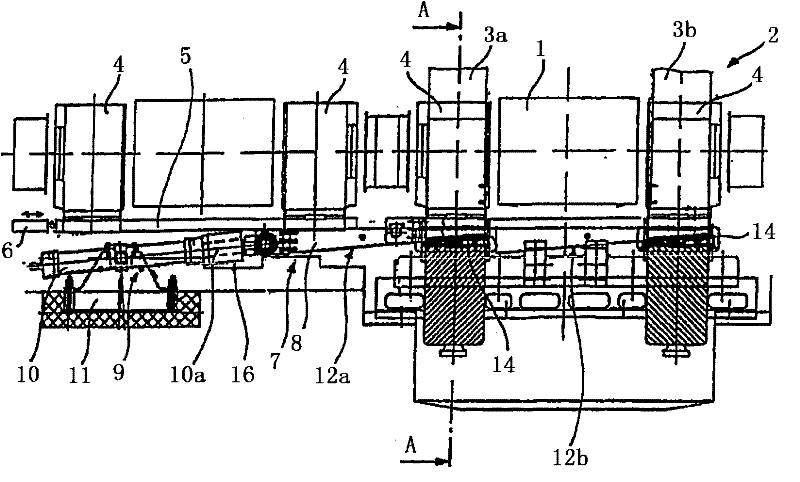

[0028] exist figure 1 shows schematically the lower roll 1 (in this particular view the lower support roll) of a four-high rolling mill stand 2 not shown in detail, which is located in the installation position between the two stands Inside the pillars 3a, 3b and laterally next to the roll stand at the roll change location. The lower roll 1 is mounted rotatably with its front journals in the roll support 4 and is guided height-adjustably on vertical guides in the support windows of the stand supports 3a, 3b. The rolls are fed in and out of the rolling stand by means of a roll changing device 5 on which the rolls are supported by means of roll chocks 4 . The displacement process takes place by means of a pressure medium cylinder 6 articulatedly coupled to the roll changing device.

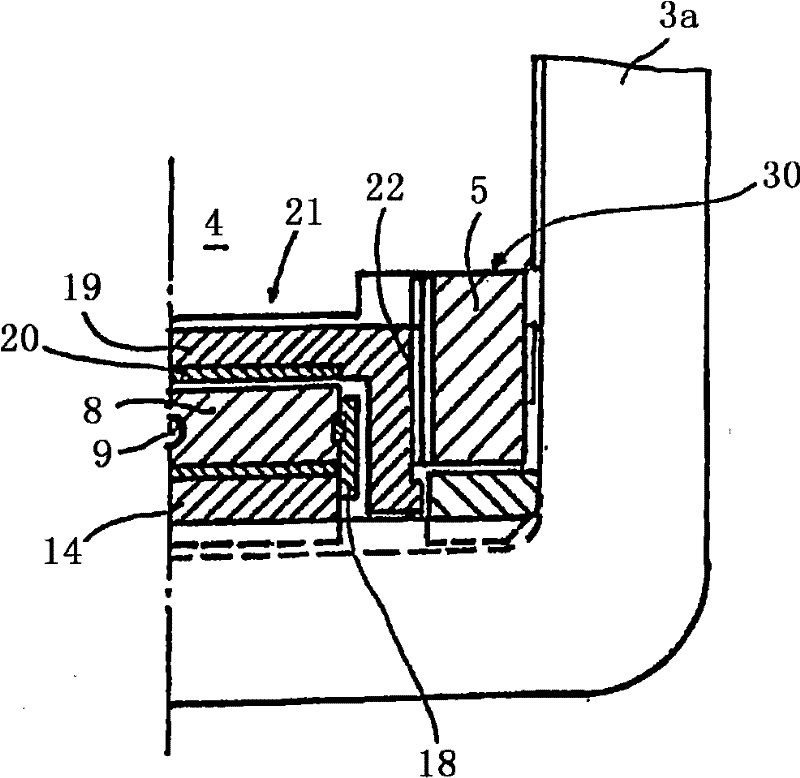

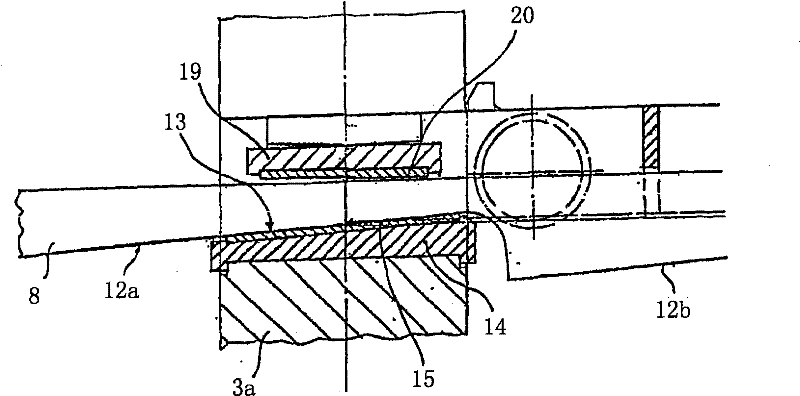

[0029] as from Figures 2 to 4As can be seen in the details of , the stepless alignment of the rolls (work rolls or backup rolls and work rolls together) to the rolling line is achieved by means ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com