Building material bending device

A technology of bending and building materials, which is applied in the field of mechanical processing tools, can solve the problems of delaying the construction period, complicated operation, heavy workload, etc., and achieve the effect of improving structural strength, easy operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

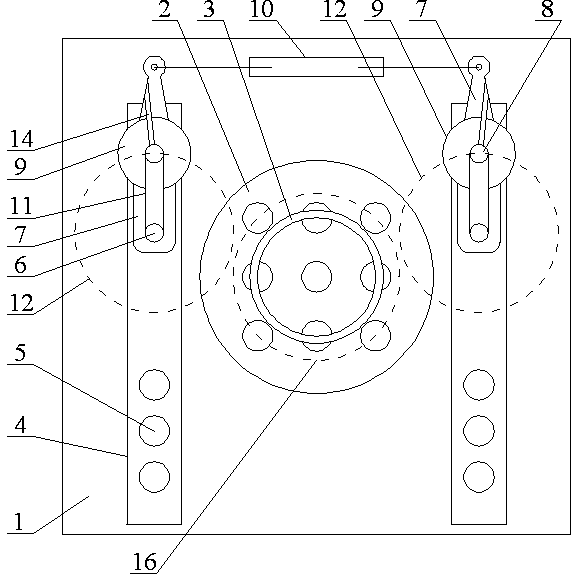

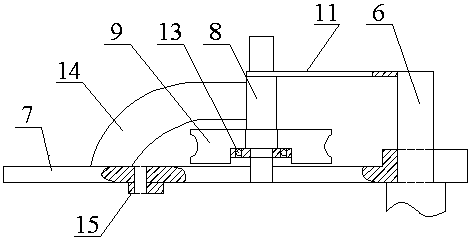

[0016] Such as figure 1 , figure 2 The shown building material bending device includes a machine 1 and a power mechanism on the machine 1. The power mechanism includes a turntable 2 on the machine 1 and a motor 16 connected to the turntable 2 under the machine 1. The turntable 2 is the same as The shaft is fixed with a drum 3, and the diameter of the turntable 2 is greater than the outer diameter of the drum 3. During the simmering and bending process, the turntable 2 can support the workpiece to ensure the structural stability of the pulley 9 and the mallet plate 7 .

[0017] On both sides of the drum 3 and the turntable 2, there are mutually parallel jacking plates 4 symmetrically arranged, and six jacking holes 5 are arranged on the jacking plate 4, and a molding mechanism is arranged to rotate in the jacking holes 5, and the molding mechanism includes a mallet. The plate shaft 6 fixedly connected to the inner end of the plate 7 and the mallet plate 7, the plate shaft 6 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com