Turbocharger comprising an actuator for opening and closing a wastegate duct

A turbocharger and control device technology, applied to gas turbine devices, valve devices, exhaust gas recirculation, etc., can solve problems such as intensification temperature problems, power density structure space problems, and the impossibility of compact packaging of turbochargers. Achieve good sealing effect and prevent scratching effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In all figures, identical or functionally identical elements and arrangements are marked with the same reference signs unless otherwise stated.

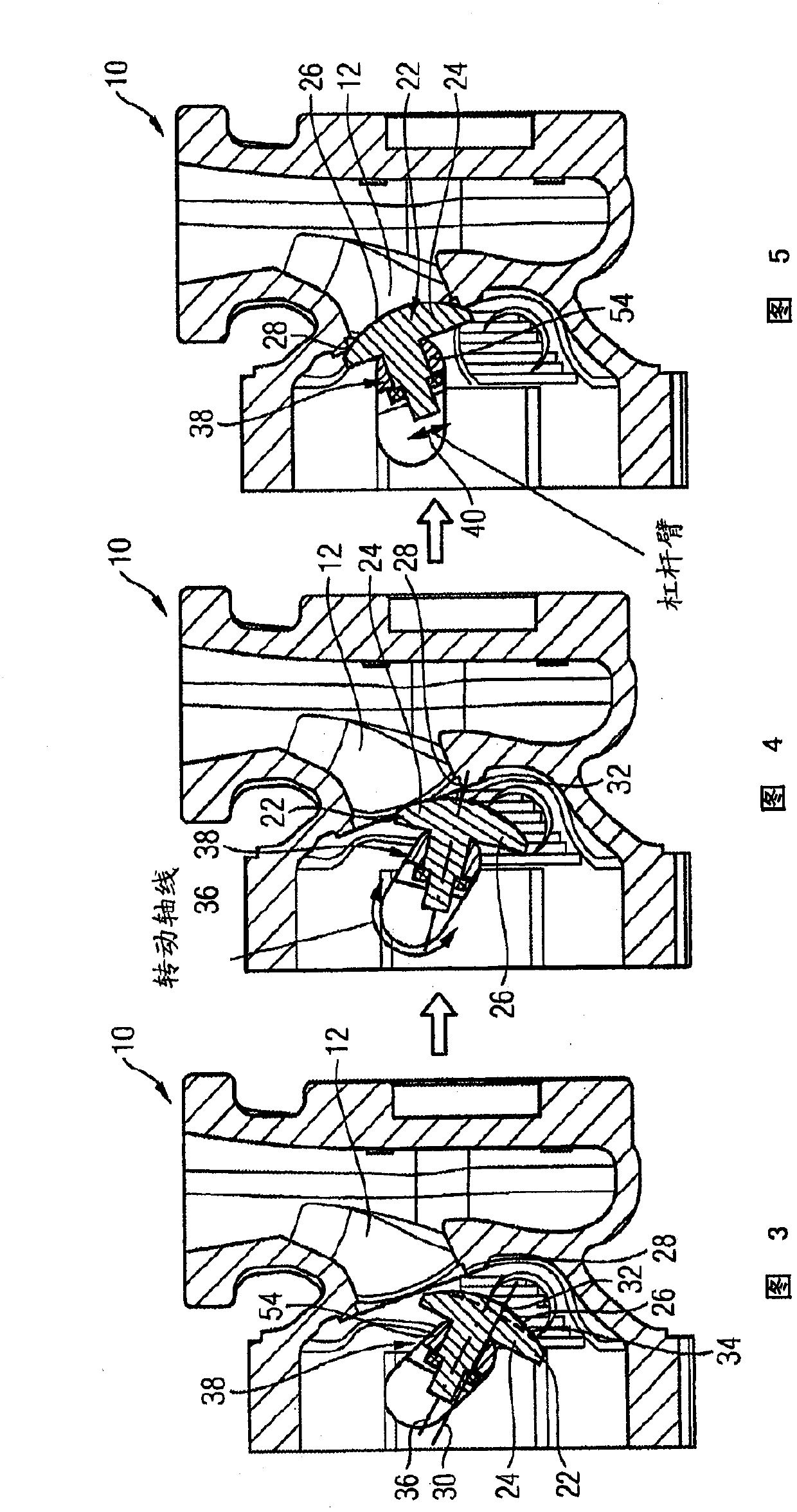

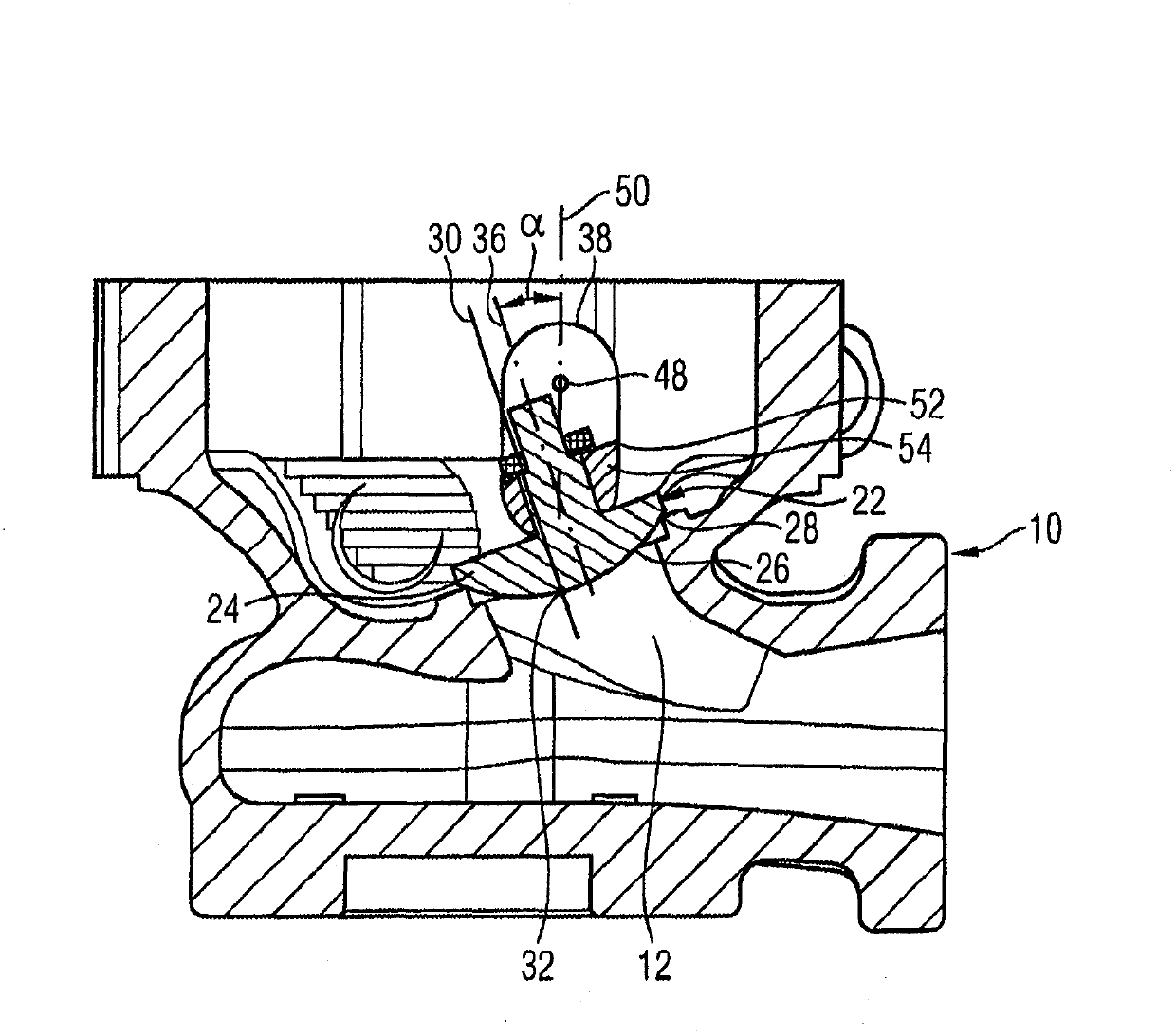

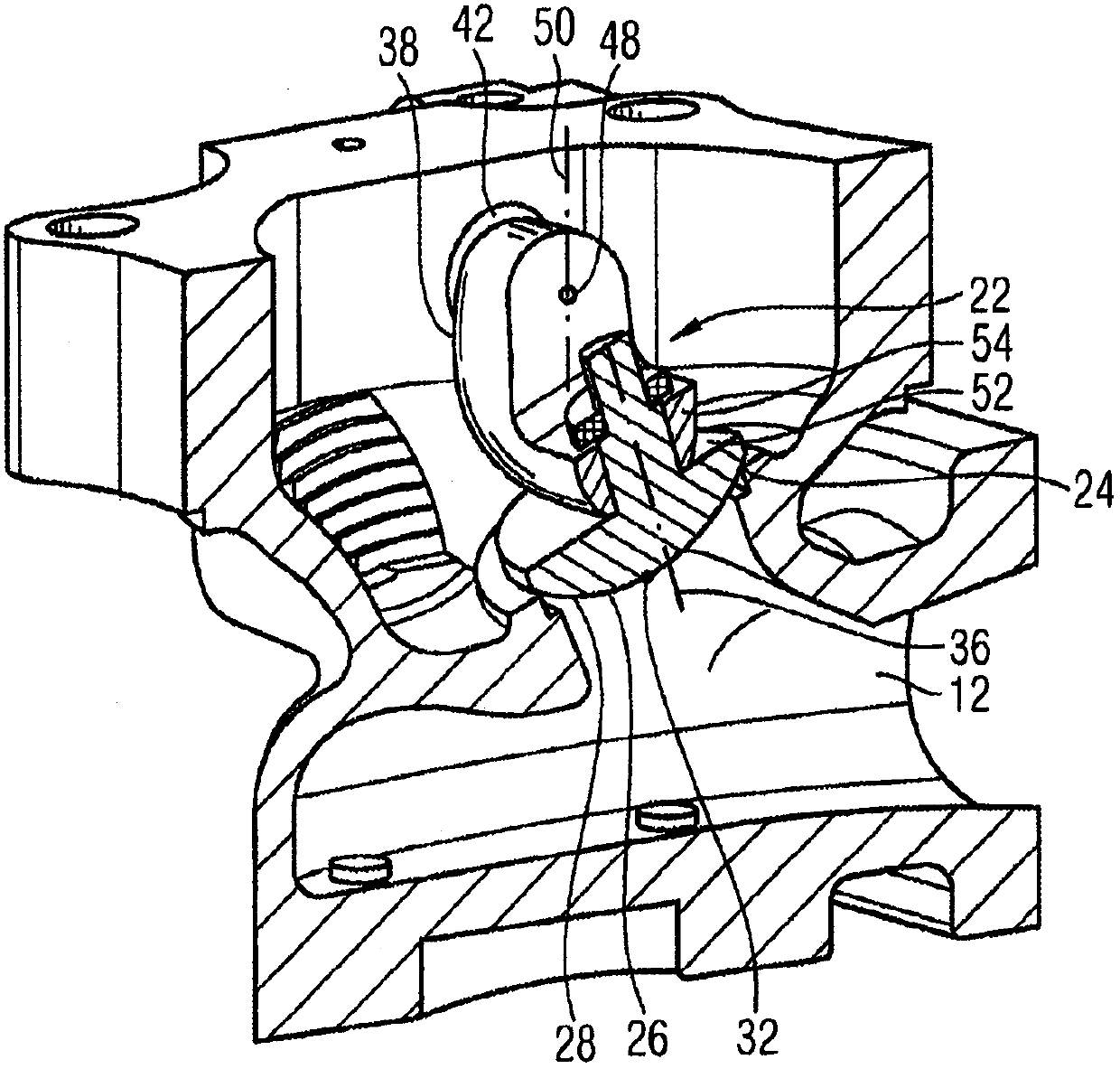

[0037] figure 1 Firstly, a sectional view of a part of the turbine housing 10 and its wastegate channel 12 is shown, wherein the wastegate channel 12 is closed by means of a wastegate valve 14 according to the prior art.

[0038] The wastegate valve 14 is fastened here on a lever element 16 . The wastegate valve 14 is swung out or deflected by turning the lever element 16 . Various opening cross-sections of the wastegate duct 12 and thus the boost pressure can be controlled via the angle of rotation β of the wastegate valve 14 . In the closed state, a “face-to-face” seal is provided between wastegate channel 12 and wastegate valve 14 . This means that, in the closed state, the wastegate valve 14 rests flat on the end section 18 of the wastegate channel 12 and seals it off. The wastegate valve 14 here has a planar or planar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com