Punch stripper

A technology of ejector and punch, which is applied to metal processing equipment, stripping devices, manufacturing tools, etc., and can solve the problems of large volume and difficult use of punch ejector

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

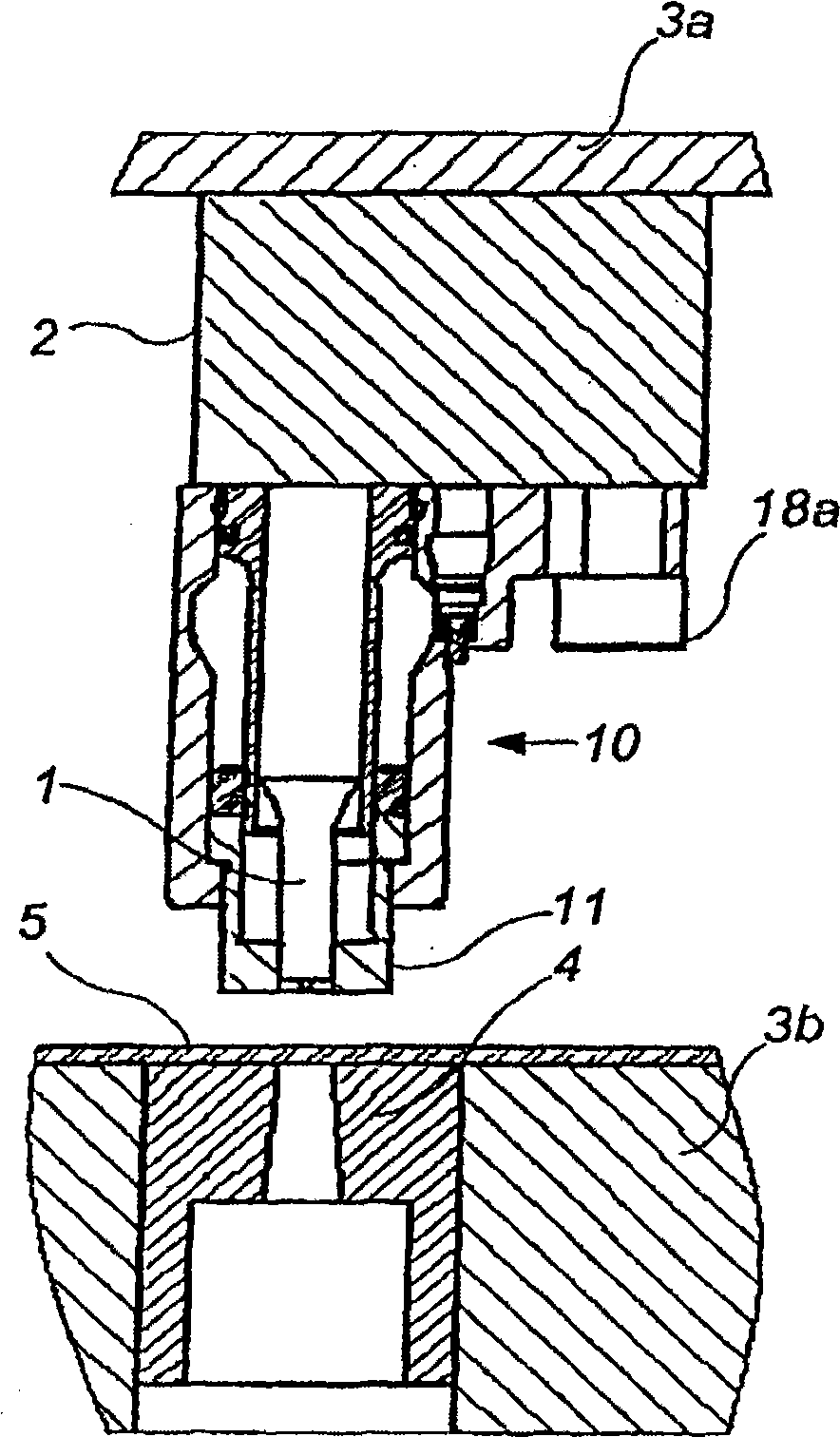

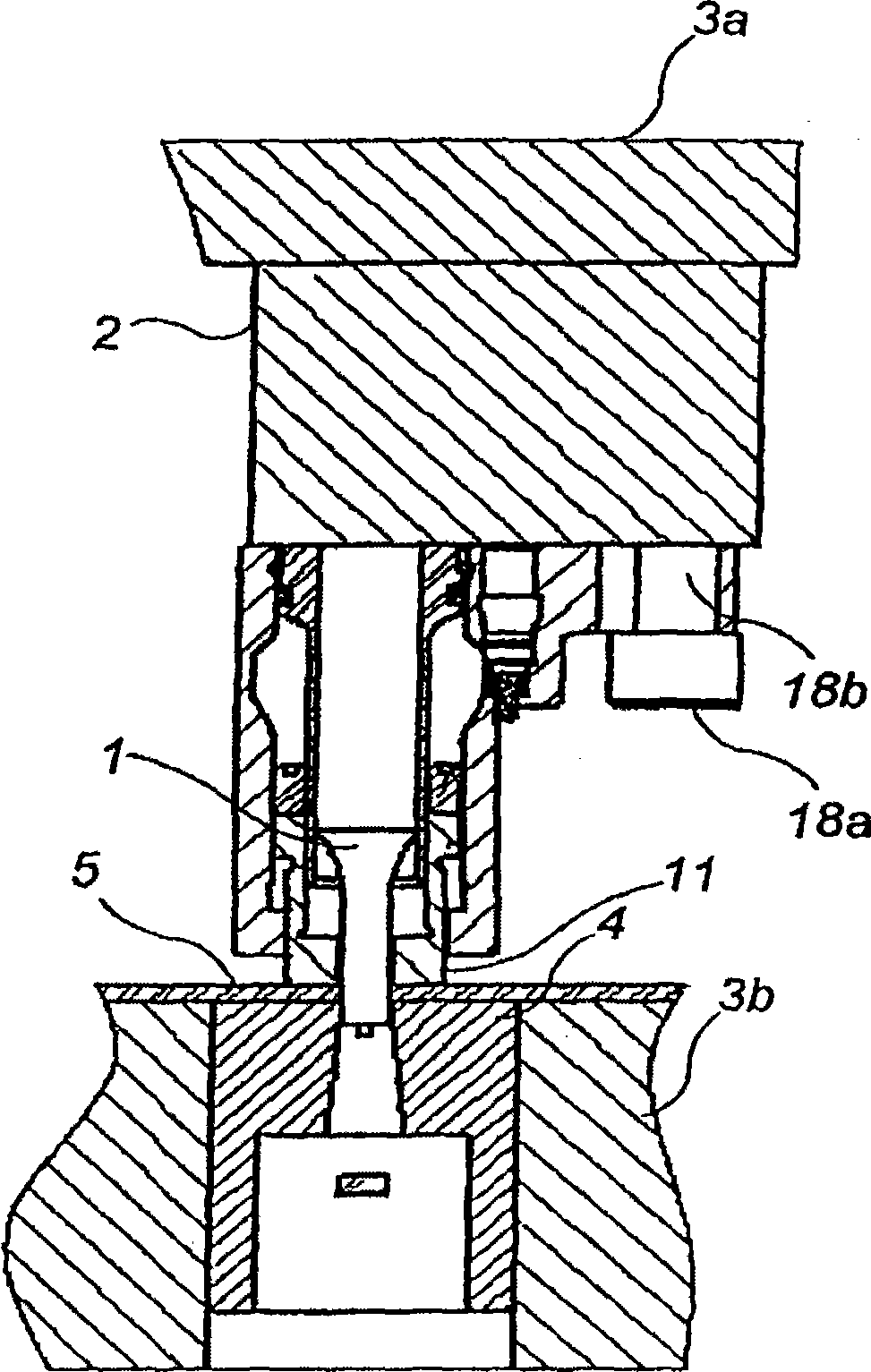

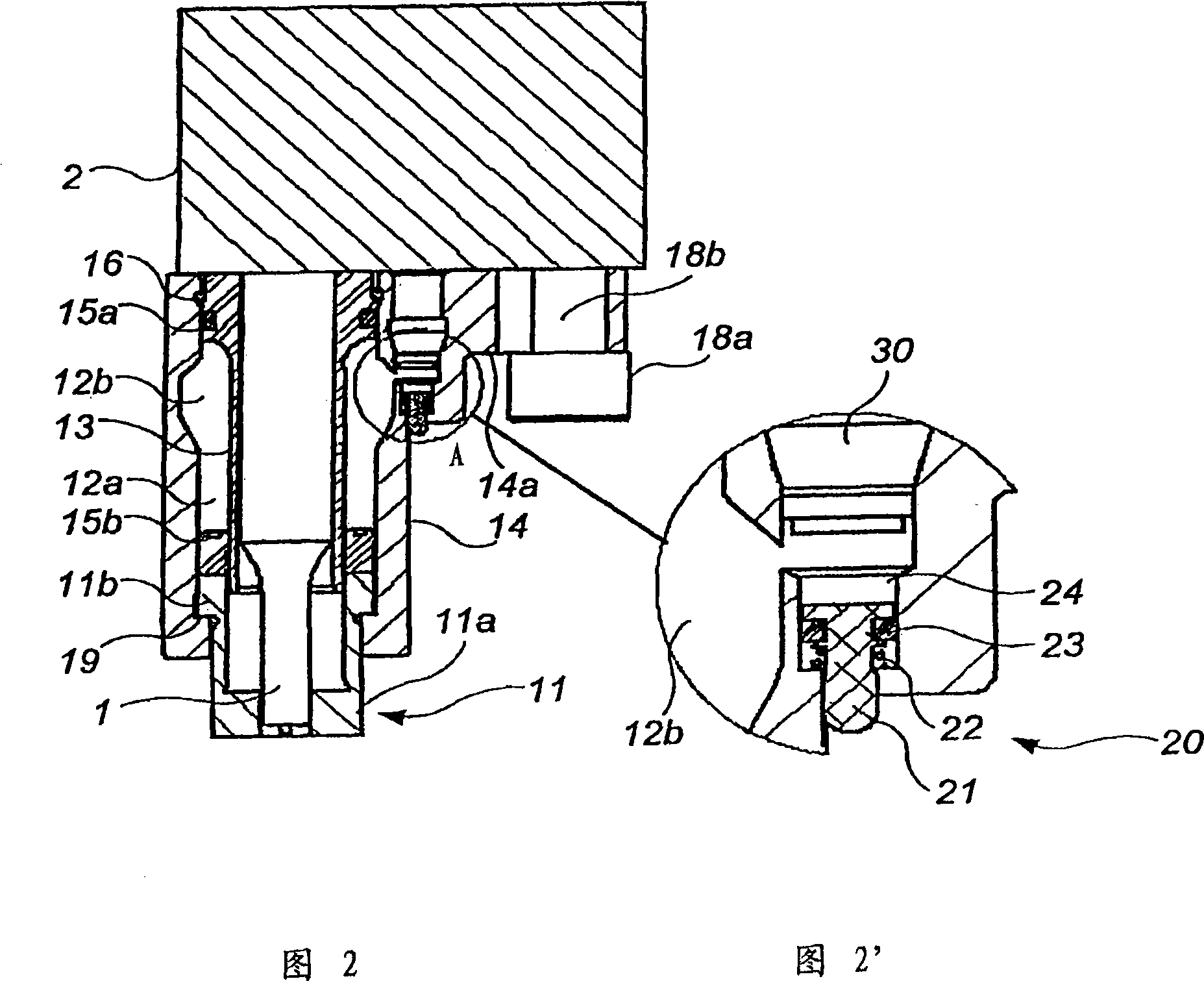

[0050] Referring now to the drawings, wherein the illustration is for the purpose of illustrating a preferred embodiment of the invention only and not for purposes of limitation, Figure 1 illustrates a press tool having an upper tool portion 3a and a lower tool portion 3b.

[0051] A punch die is provided in the lower tool part 3b. A workpiece 5, which may be a sheet metal, is arranged to be machined by the press tools 3a, 3b.

[0052] The upper tool part 3 has a punch plate 2 on which the punch 1 has a punch stripper, which is fastened by fastening means 18a, 18b (such as screws, bolts, rivets, etc.) . Such as Figure 1a , 1b As shown in and 2, the fastening means may be a mounting screw / tightening bolt 18a, the shank of which is arranged in a hole 18b in the base 14a of the punch ejector.

[0053] In a non-limiting example of the invention, the punch holder plate 2 can be designed in any of the ways disclosed in US 6182545 B1 (i.e. the punch ejector can have a locking me...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap