Differential pressure type flow sensor capable of realizing direct pressure tapping and two-way measurement

A flow sensor and two-way measurement technology, which is applied in the direction of detecting fluid flow by measuring pressure difference, volume/mass flow generated by mechanical effects, etc., can solve the problems of high installation requirements, low measurement accuracy, and large floor space. Achieve good long-term stability, high measurement accuracy, and reduce floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

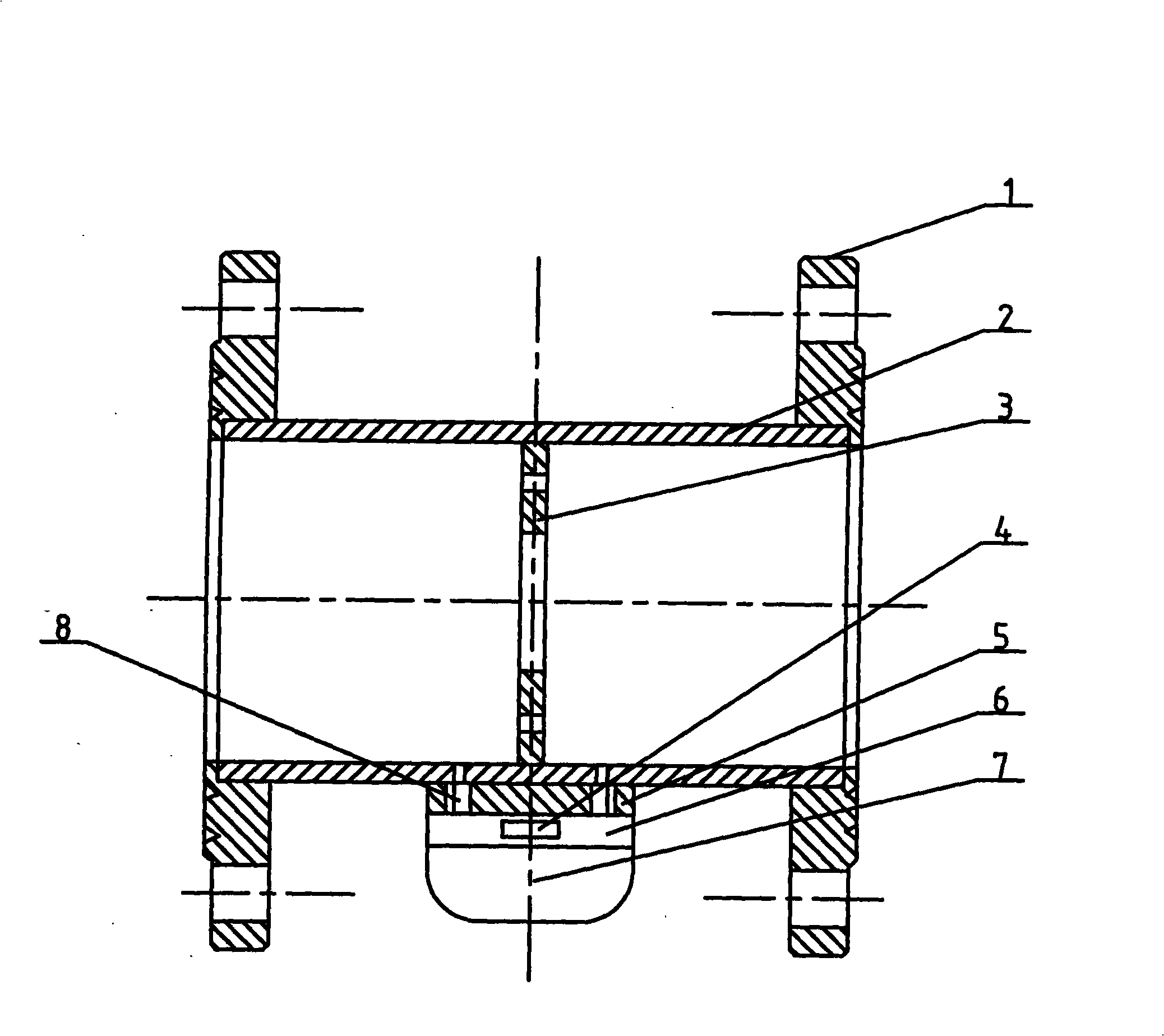

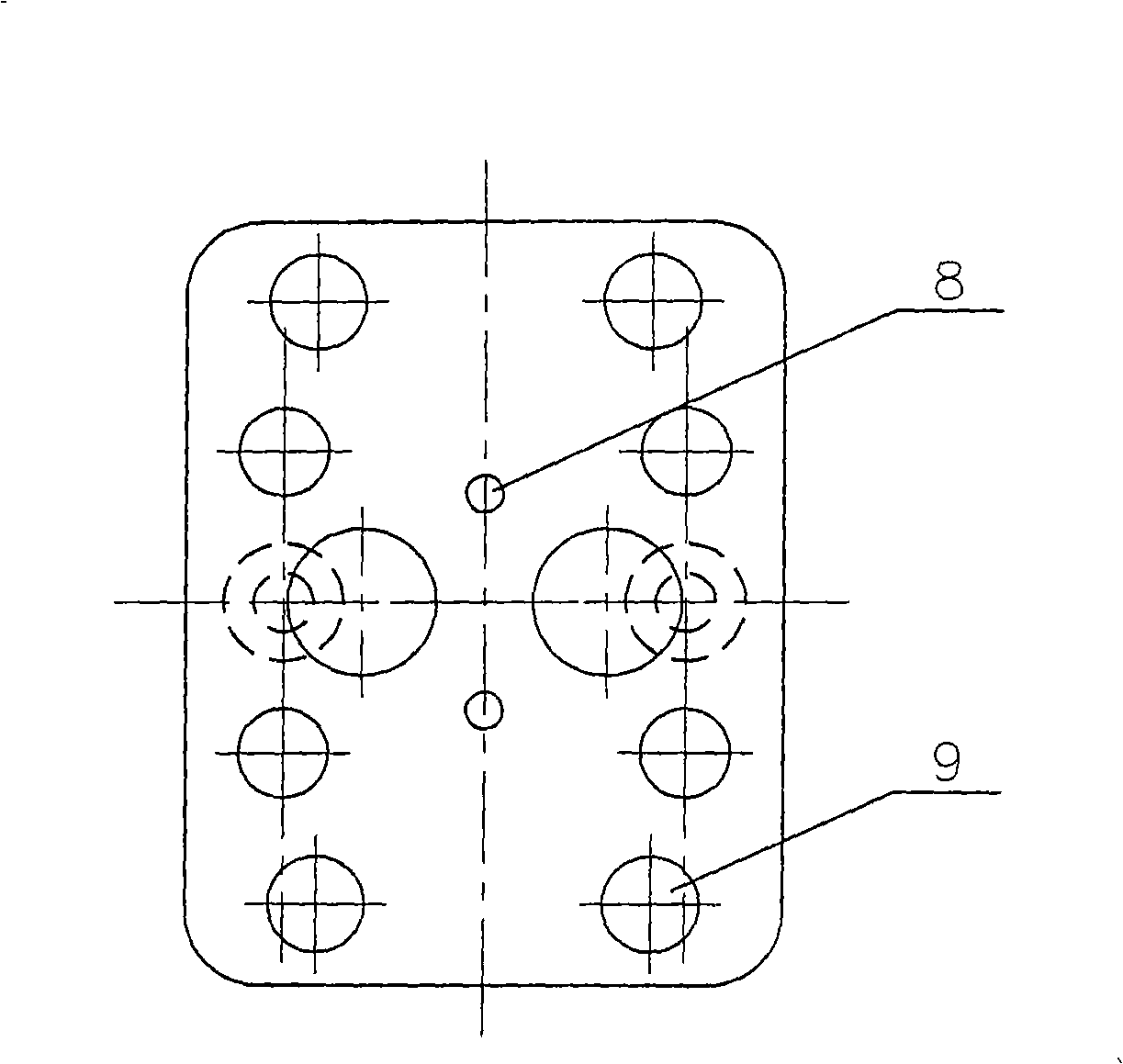

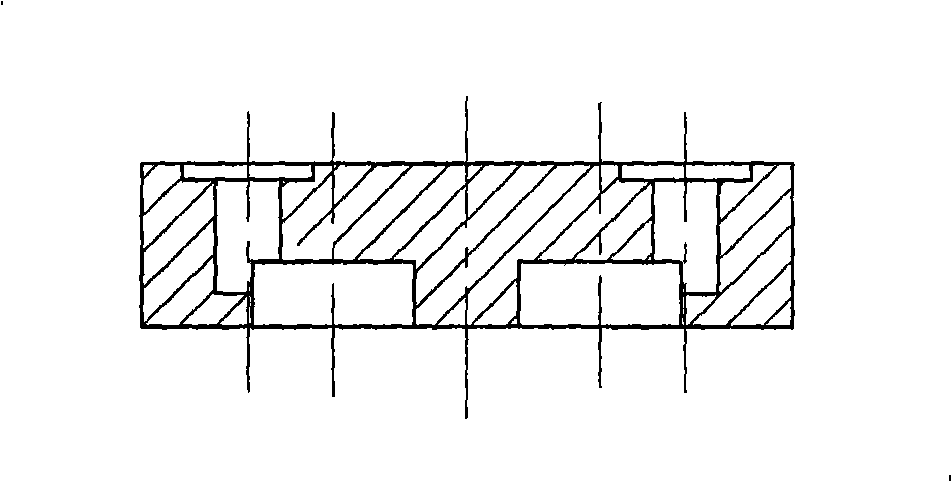

[0024] like figure 1 As shown, the present invention has a tubular housing 2, flanges 1 for connecting with the measured pipeline are welded at both ends of the housing 2, and double-sided symmetrical throttle plates 3 are welded in the housing 2; as figure 1 , figure 2 and image 3 As shown, two pressure introduction holes 8 are processed on the pipe wall of the shell 2, and the said pressure introduction holes 8 are located on the front and rear sides of the double-sided symmetrical throttle plate 3, and on the shell 2 corresponding to the pressure introduction holes 8 A pressure-taking membrane box 6 is installed through a connecting plate 5, and pressure introduction holes are processed on the connecting plate 5 and the pressure-taking membrane box 6; Surface pressure-taking type differential pressure transmitter 4 (3051), outside the pressure-taking membrane box 6 is also connected with a differential pressure flow converter 7 with a flow output of 4-20mA and a zero po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com