Connector and plug thereof

A technology of connectors and plugs, which is applied in the direction of connection, fixed connection, and parts of connection devices, etc., can solve the problems of high and low frequency contact bending damage, reduce the life of connector plugging and unplugging, and affect the performance of connectors, etc., to achieve Enhanced electrical conductivity and improved plug-in life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

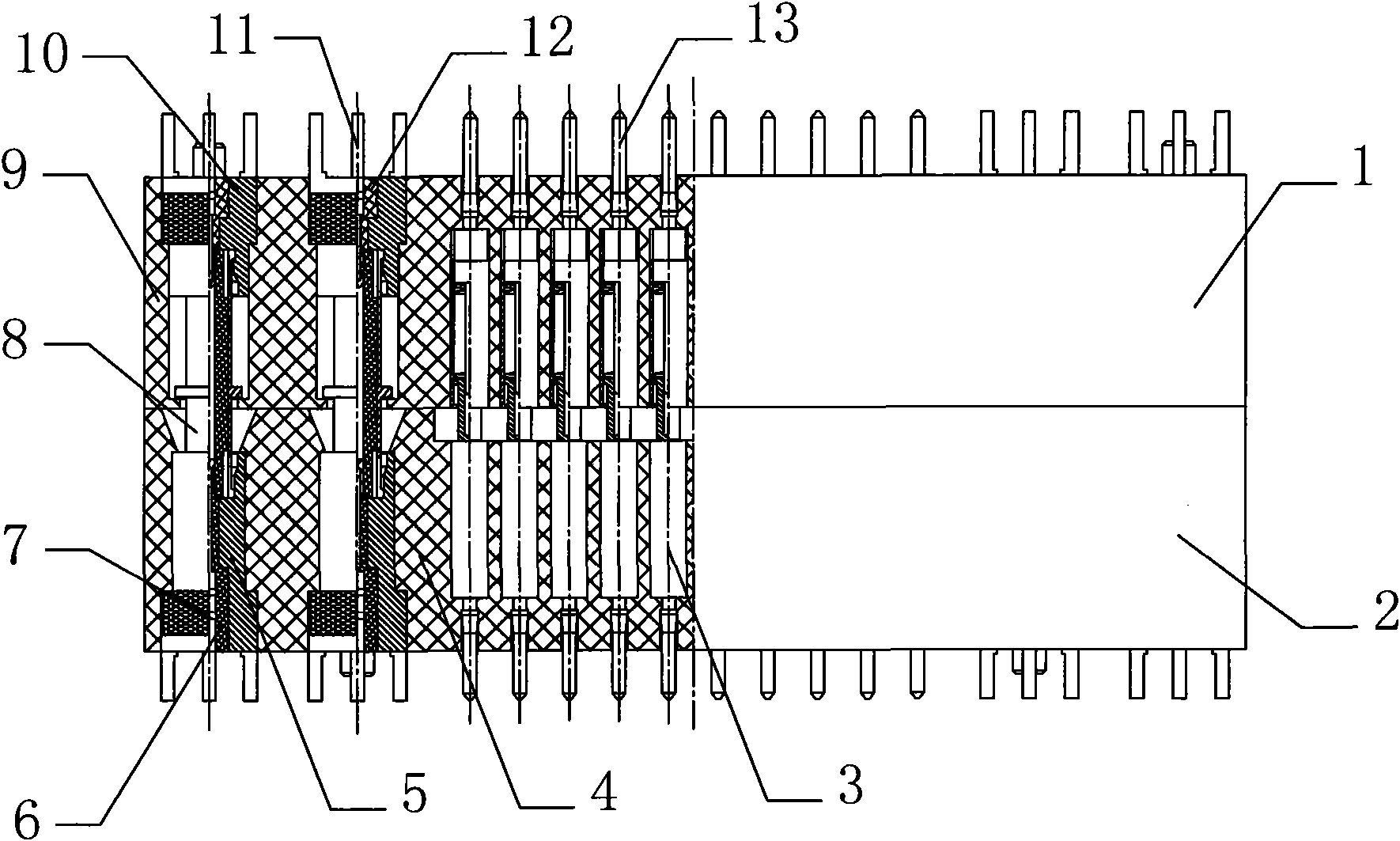

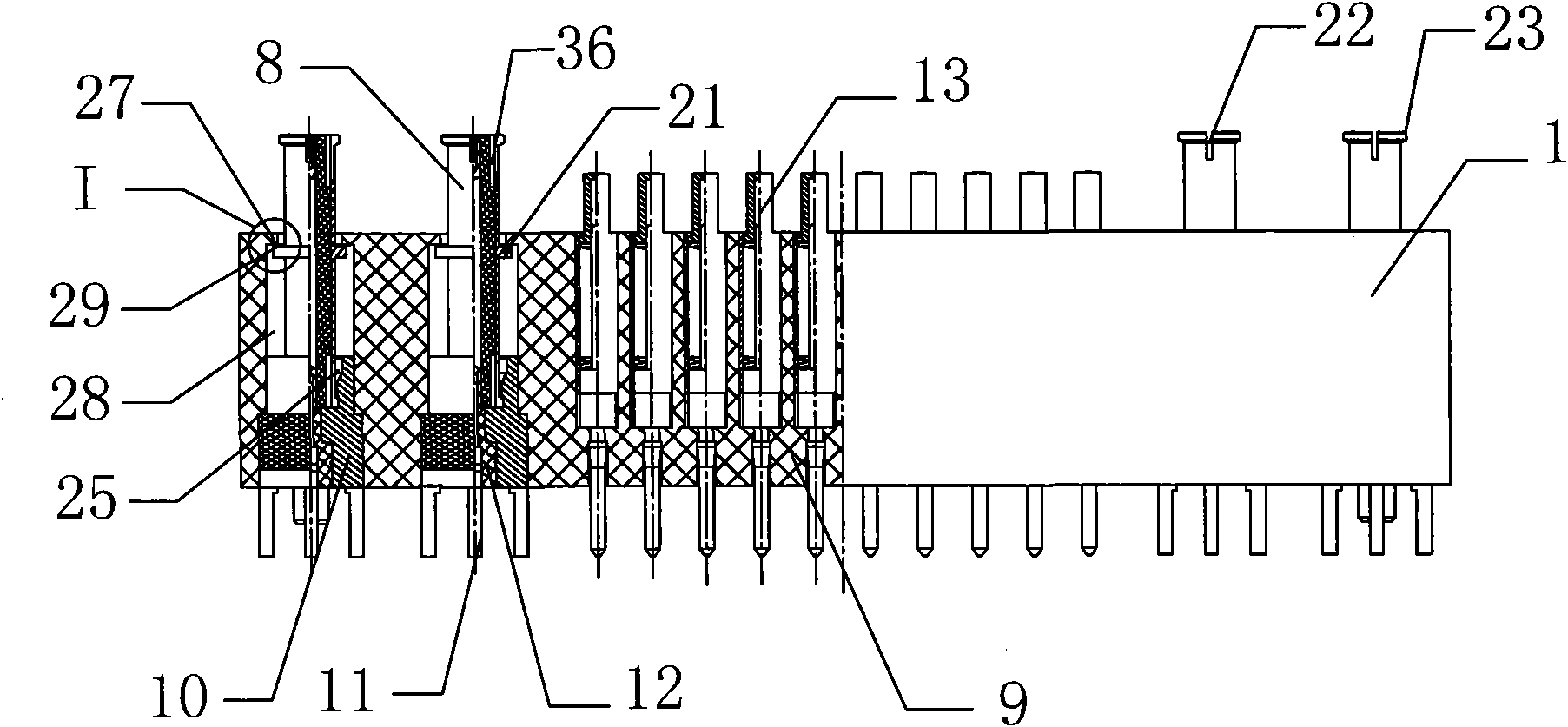

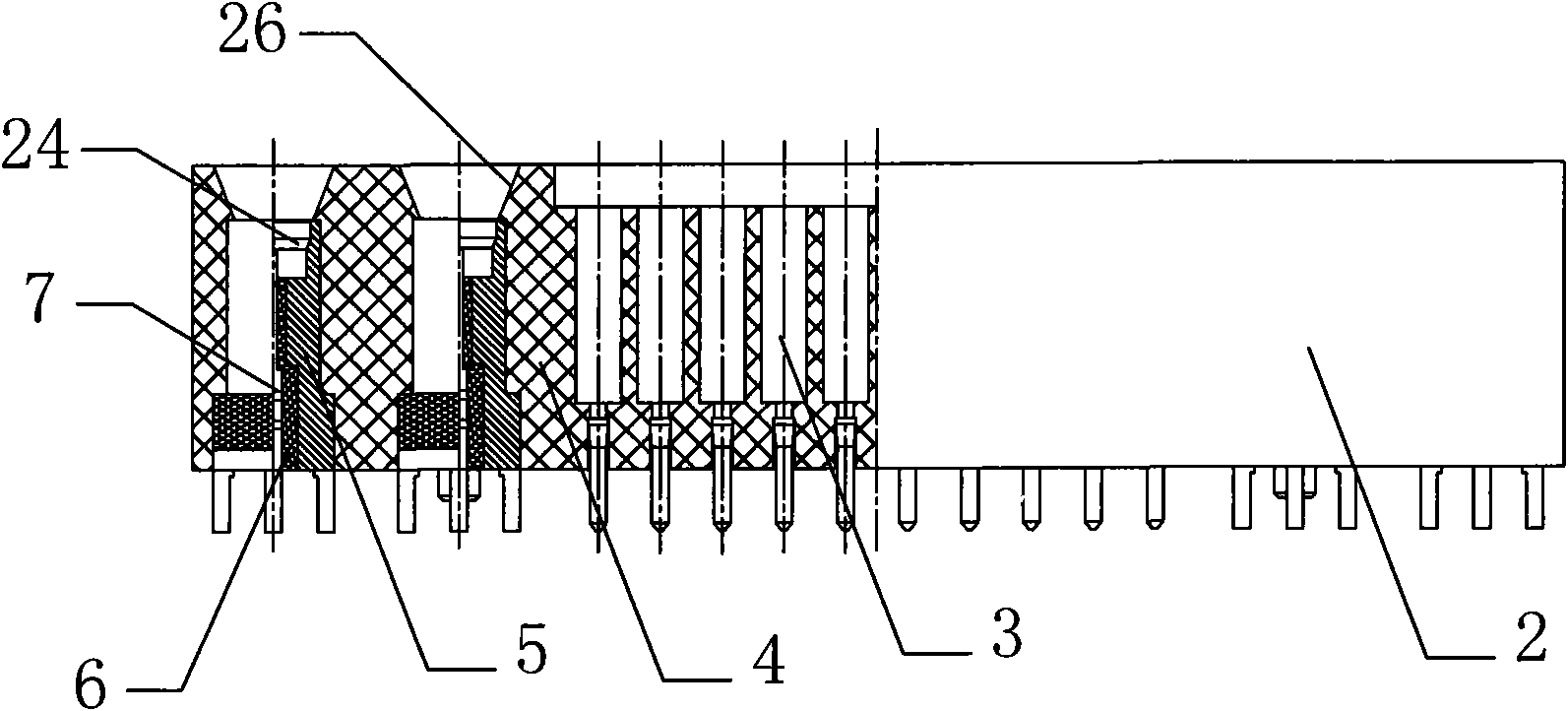

[0023] figure 1 , 2, 3, 4, 5, and 6, the connector of the present invention includes a plug 1 and a socket 2. The plug 1 is a plug insulator 9, and the plug insulator 9 is provided with a plug high-frequency contact piece installation cavity and a plug low-frequency contact piece installation cavity extending along the insertion direction, and the plug low-frequency contact piece installation cavity is fixedly inserted with a plug low-frequency contact piece 13. The plug high-frequency contact piece installation cavity is provided with a plug high-frequency contact piece; the plug high-frequency contact piece installation cavity is provided with a retaining edge 27 near the plug insertion end, and the plug high-frequency contact piece includes axially movable plugs together. High-frequency adapter 8 and plug high-frequency receptacle, high-frequency adapter 8 peripheral surfaces are provided with boss 21, also can be jump ring or positioning pin certainly, high-frequency adap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com