Method for preparing and purifying solar grade silicon crystal

A purification method, a solar-grade technology, applied in crystal growth, chemical instruments and methods, self-melting liquid pulling method, etc., can solve problems such as inability to work, and achieve the effects of increasing productivity, reducing oxygen content, and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

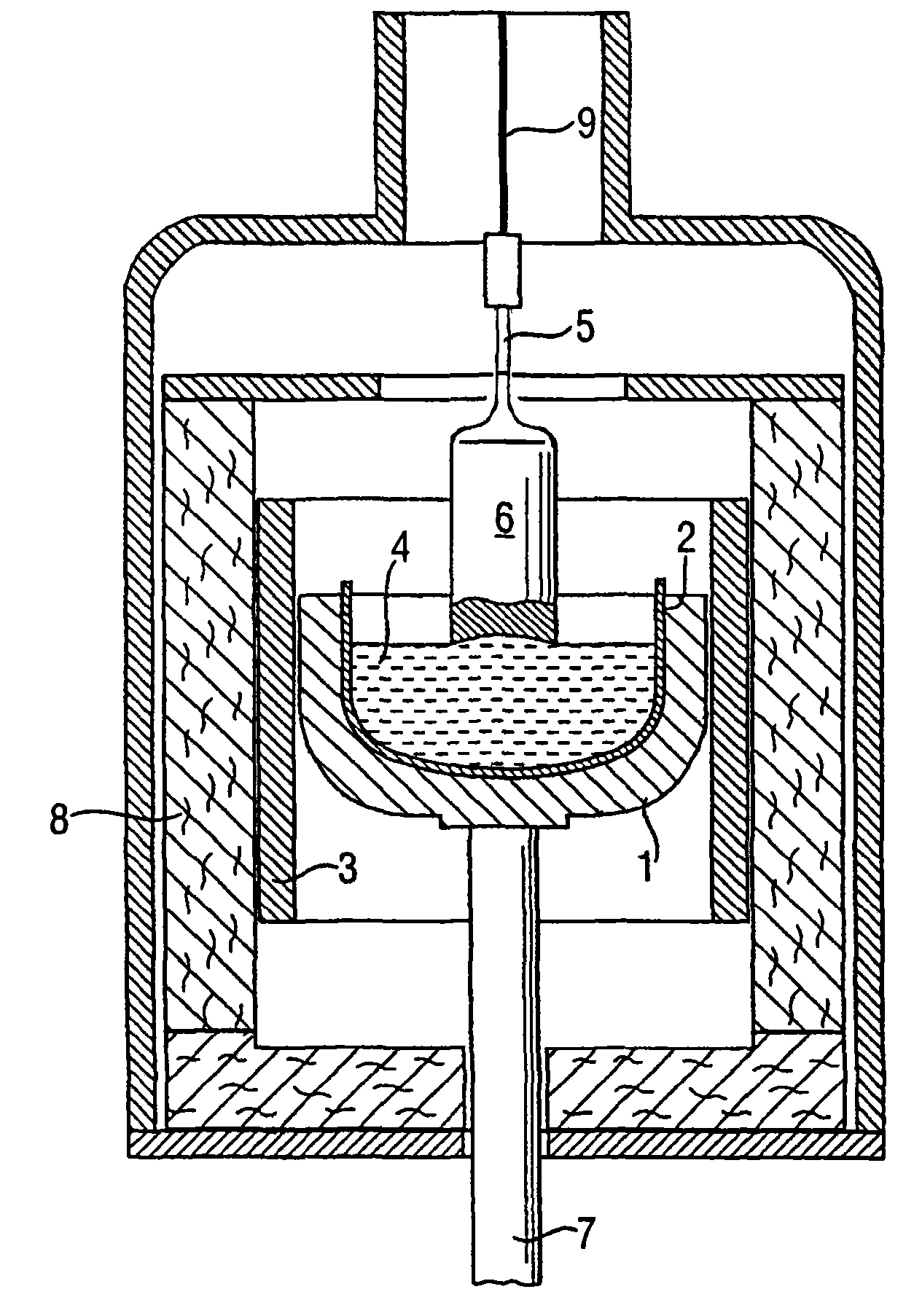

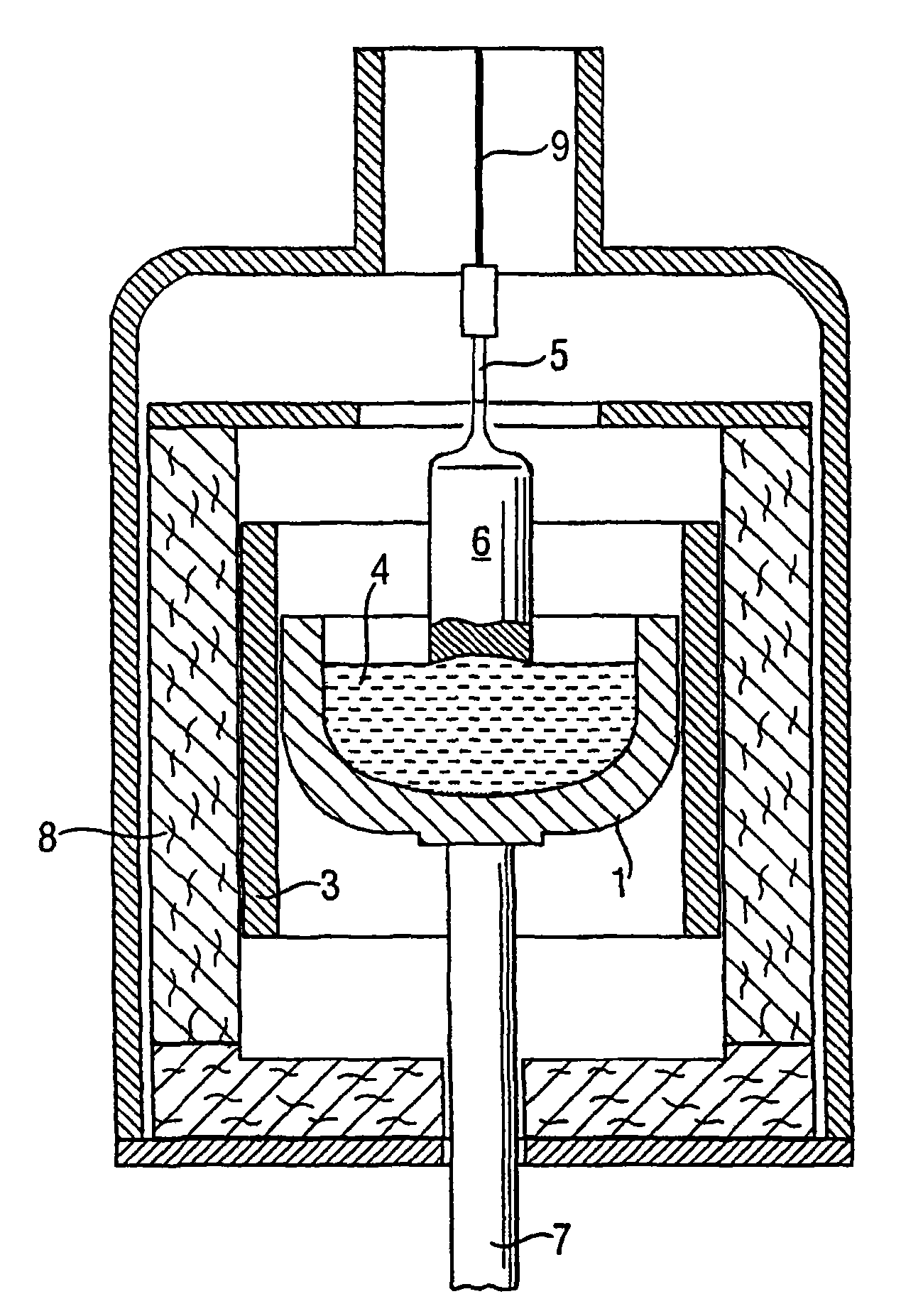

[0037] see figure 1 , figure 1 It is a typical longitudinal section of a CZ method crystal pulling furnace. The silicon raw material usually used for growing silicon crystals is placed in the inner crucible, that is, the quartz crucible 2 , heated by the heater 3 , and melted into silicon melt 4 under the protection of the insulation material 8 . The quartz crucible 2 is placed in the outer crucible, that is, the graphite crucible 1 . And the graphite crucible is placed on the crucible shaft 7 that can be lifted. In the CZ method, the crystal growth interface is in the middle of the free surface of the silicon melt 4 . By properly designing the heating power and given the appropriate rotation speed of the crucible shaft 7 and the seed crystal 5, the seed crystal 5 is pulled by the seed crystal rope 9 driven by the traction mechanism to induce the silicon melt 4 to grow into a cylindrical Crystal 6.

[0038] During the growth process of the crystal 6 , the main component o...

Embodiment 2

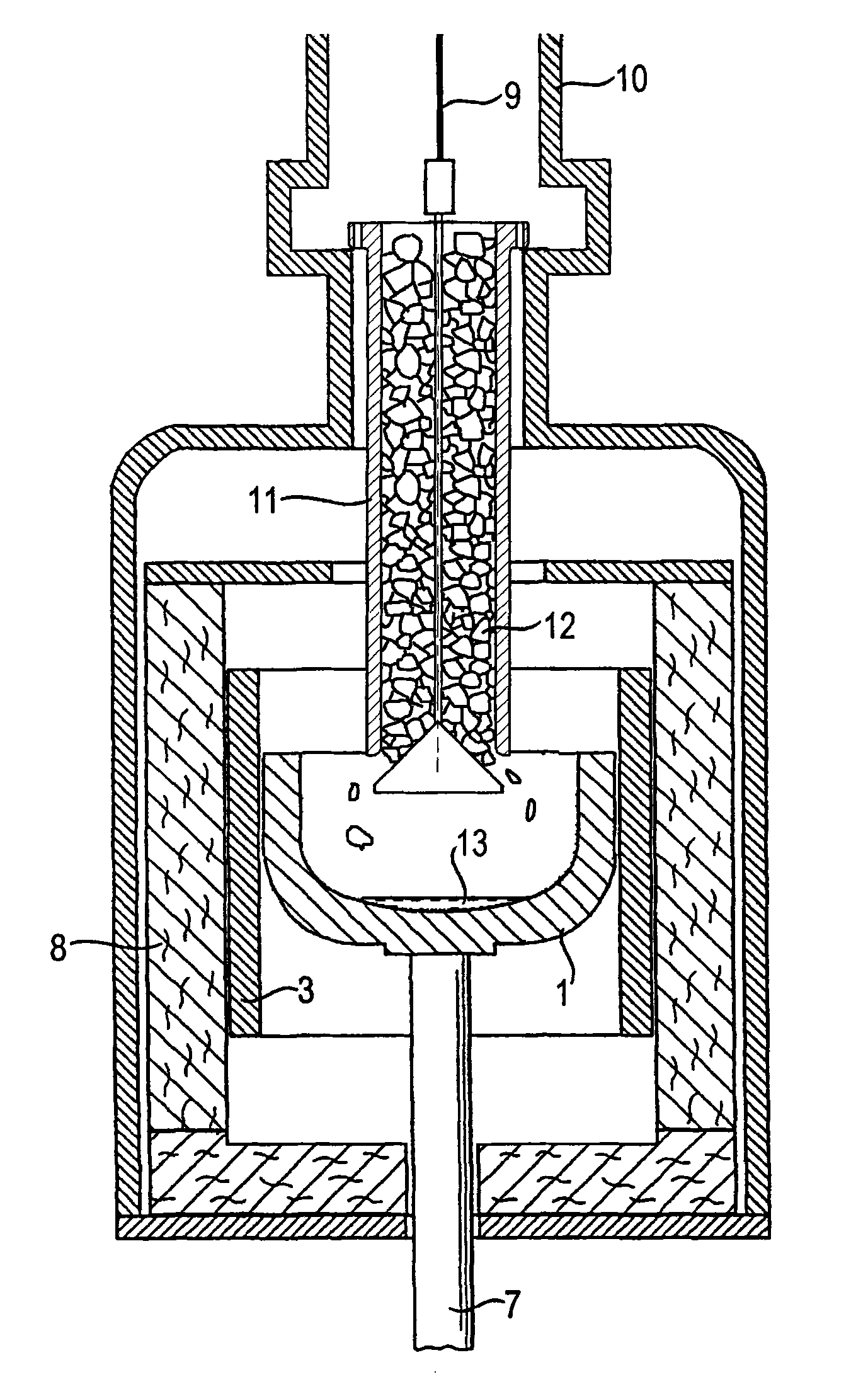

[0043] Adopt the same technological process of embodiment 1. The difference is that the charging process is carried out by a feeder 14 installed on the furnace cover for side feeding. Such as Figure 4 shown. The silicon raw material 15 stored in the feeder 14 is granular, with an equivalent diameter between 0.5 mm and 15 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap