Dustproof cover structure for lens

A dust-proof cover and lens technology, applied to the camera body, optical filter for photography, optics, etc., can solve the problem of different closing force of the feather, and achieve the effect of overcoming the incomplete closure of the feather

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

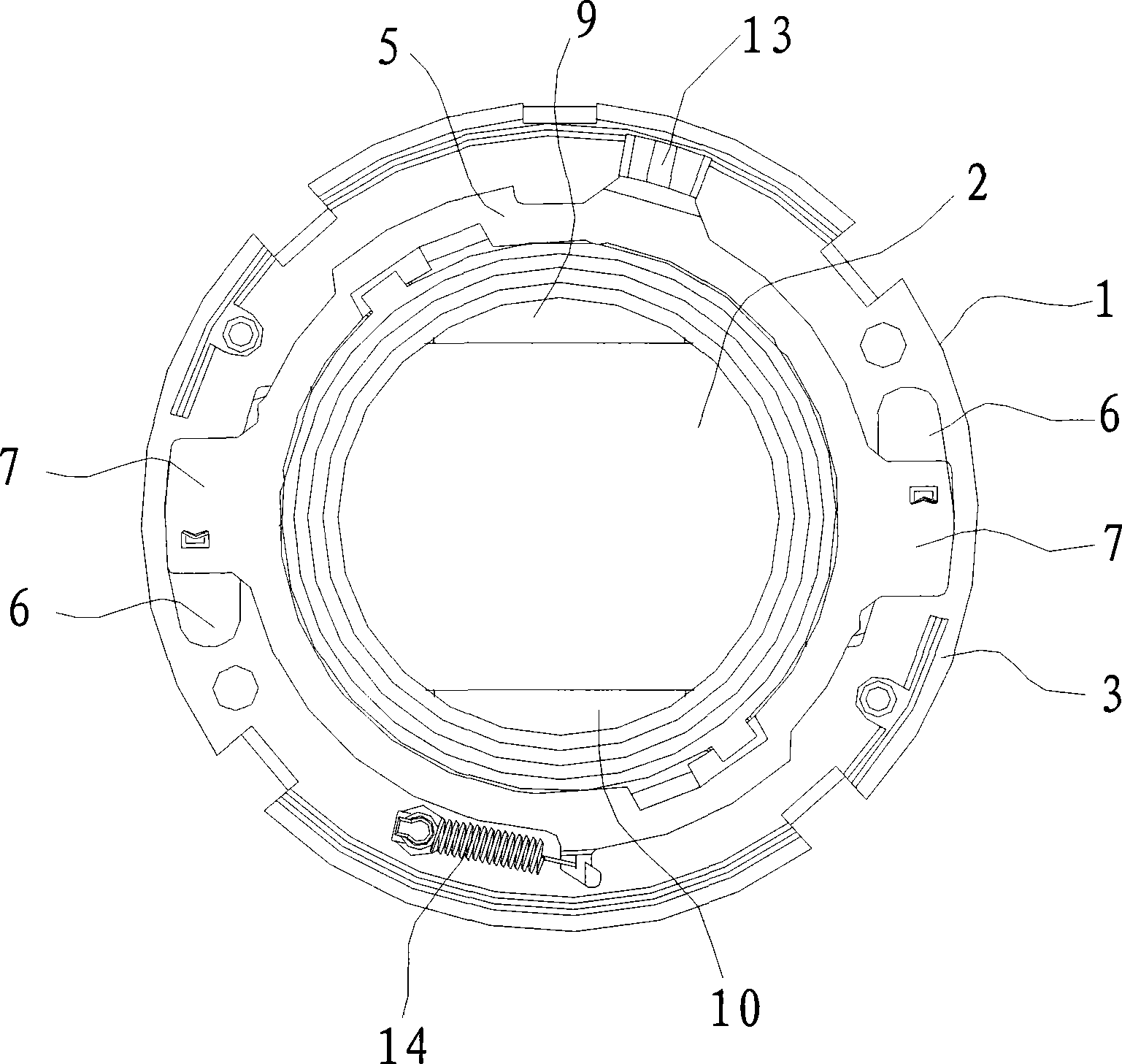

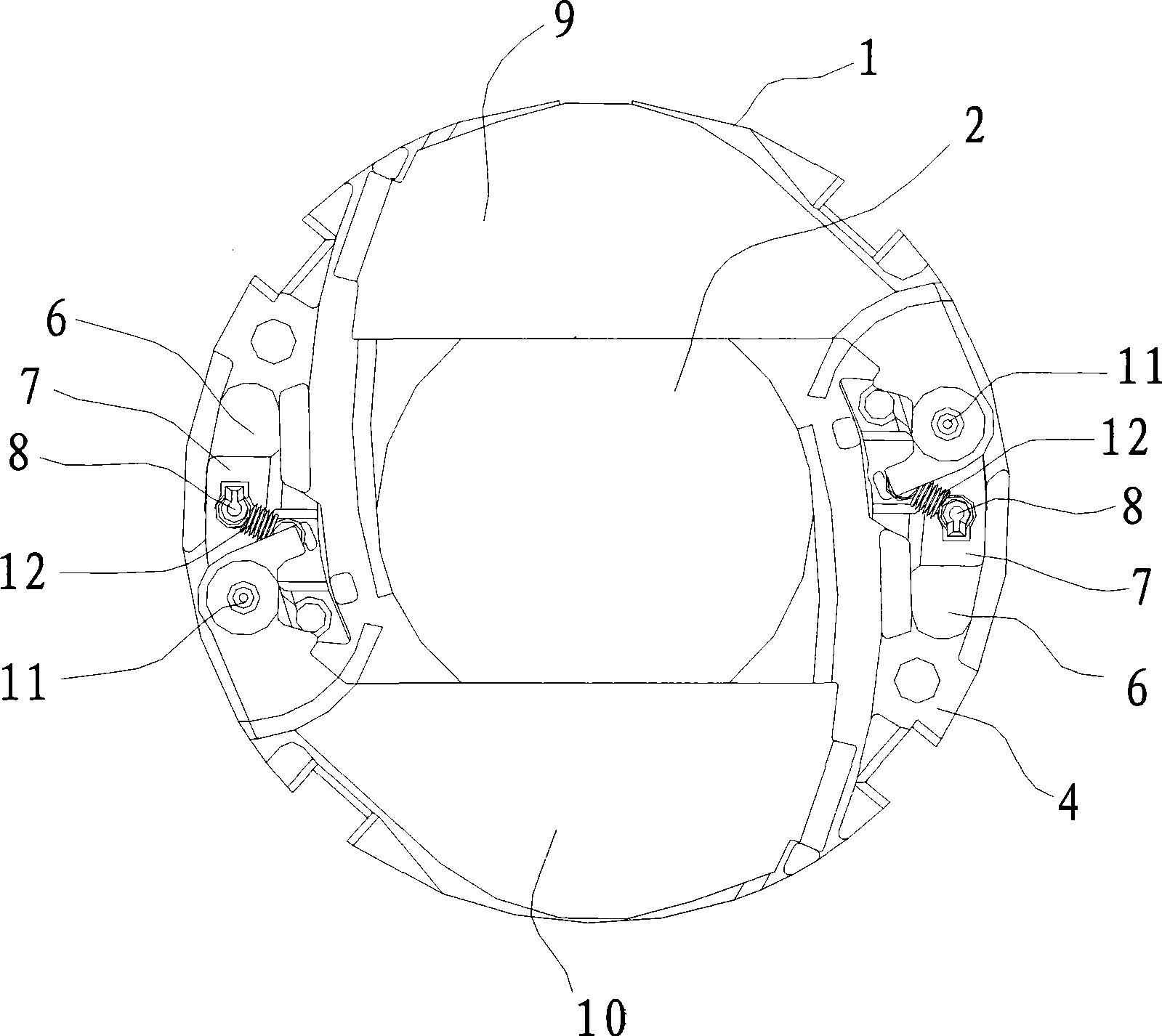

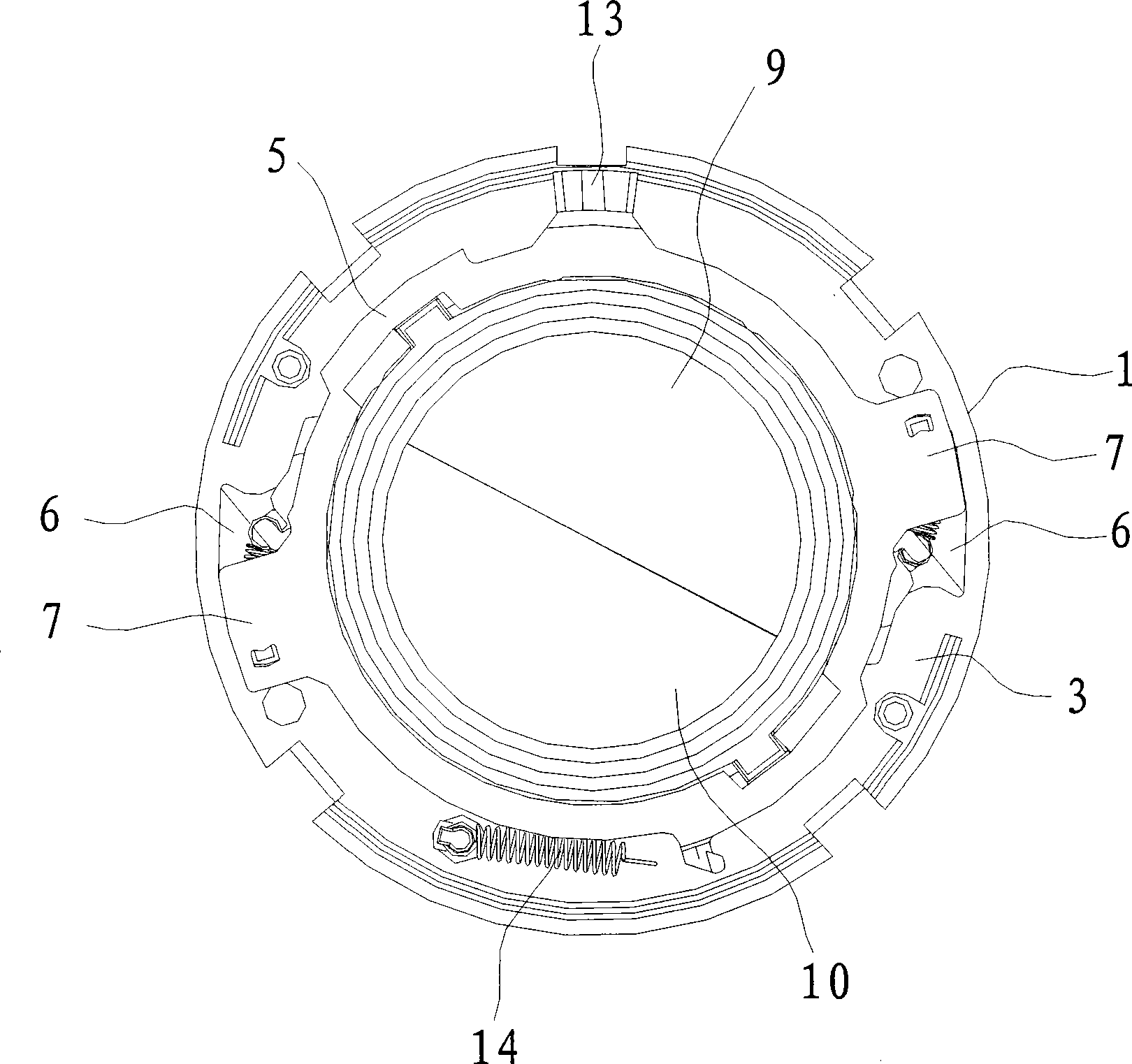

[0027] Such as Figure 5 and Figure 6 As shown, the dustproof cover structure 100 of the present invention includes a dustproof base 101 , an annular inner link 102 , an annular outer link 103 , a first feather 104 and a second feather 105 . The dustproof base 101 is provided with a central hole 106 to form a ring shape; the central hole 106 is used to allow light to pass through and enter the lens. The dust-proof base 101 includes a first surface 107 and a second surface 108 , and a protruding inner ring 109 is provided on the first surface 107 . The inner ring 109 extends outward from the inner diameter surface of the dustproof base 101 . The inner connecting rod 102 is sleeved outside the inner ring 109, and the outer connecting rod 103 is sleeved outside the inner connecting rod 102, and the three are concentric.

[0028] On the second surface 108, the first feather 104 and the second feather 105 are provided. refer to Figure 8 and Figure 10 , the first feather 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com