Composite rotary pdc drill bit

A rotary cutting, drill bit technology, used in drill bits, earth-moving drilling, drilling equipment, etc., can solve the problems that ordinary PDC drill bit cutting teeth cannot penetrate into the formation well, increase drilling cycle, speed up drill bit wear, etc., to shorten the time The effect of drilling cycle, improving adaptability and reducing drilling cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings.

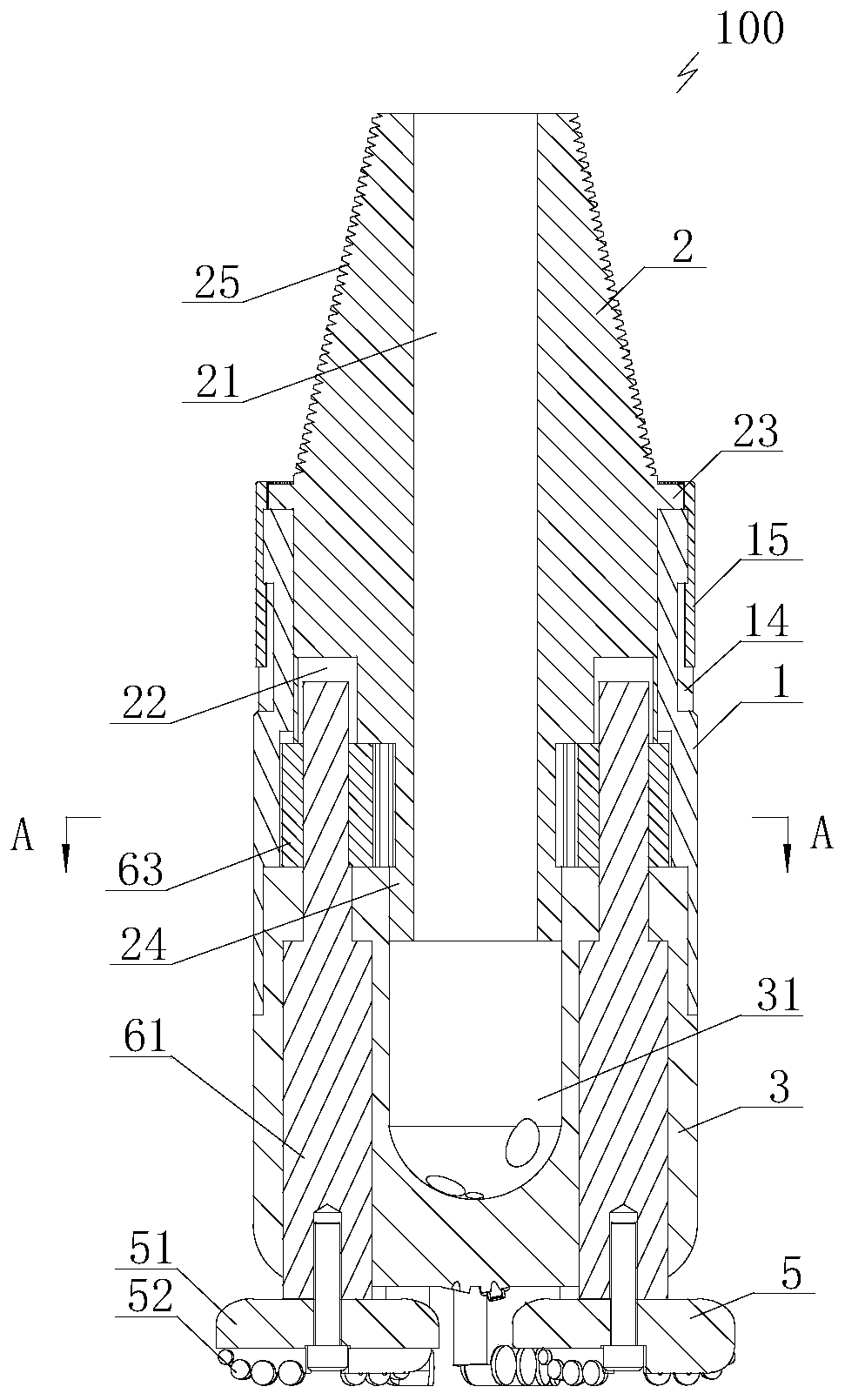

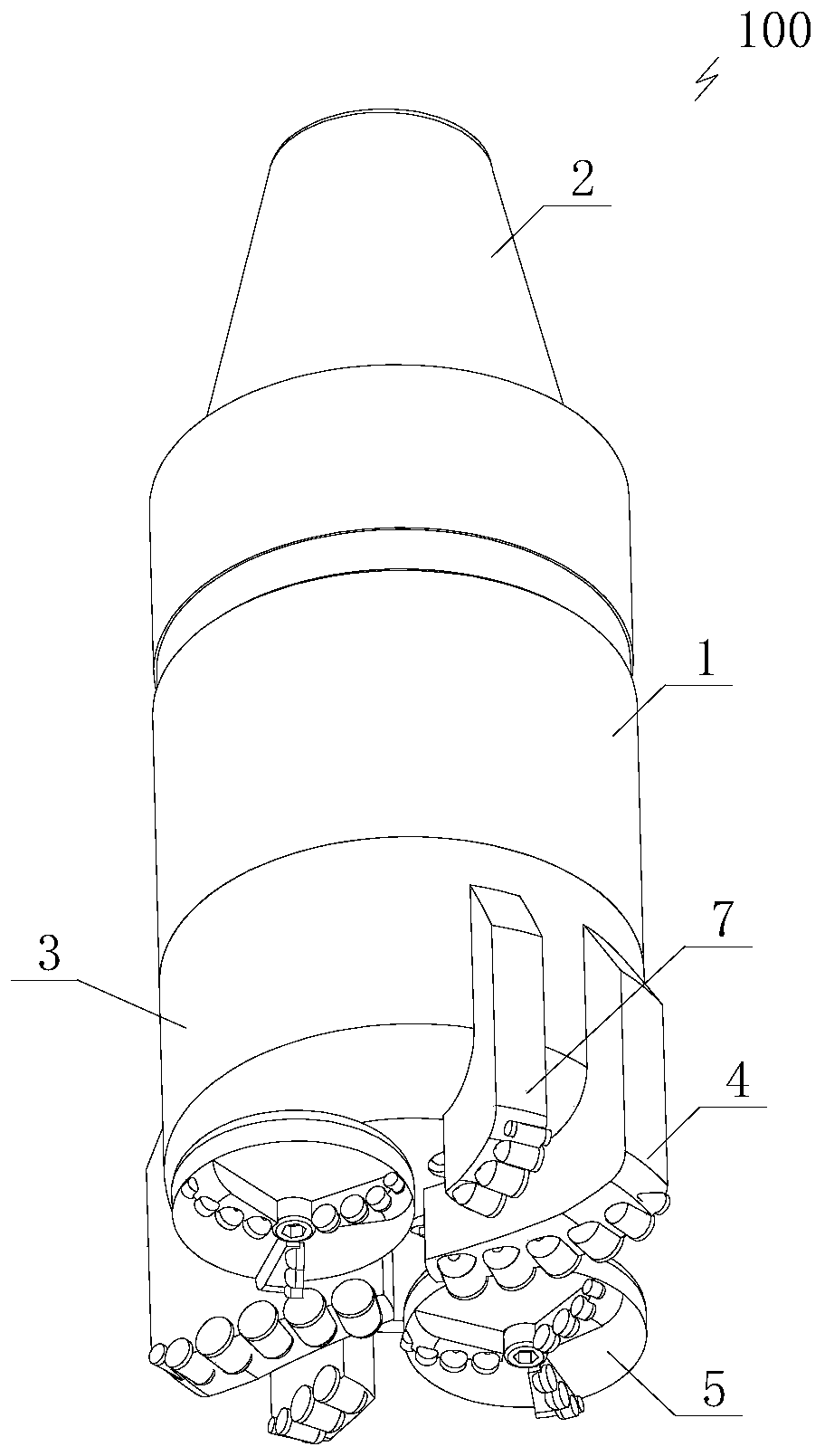

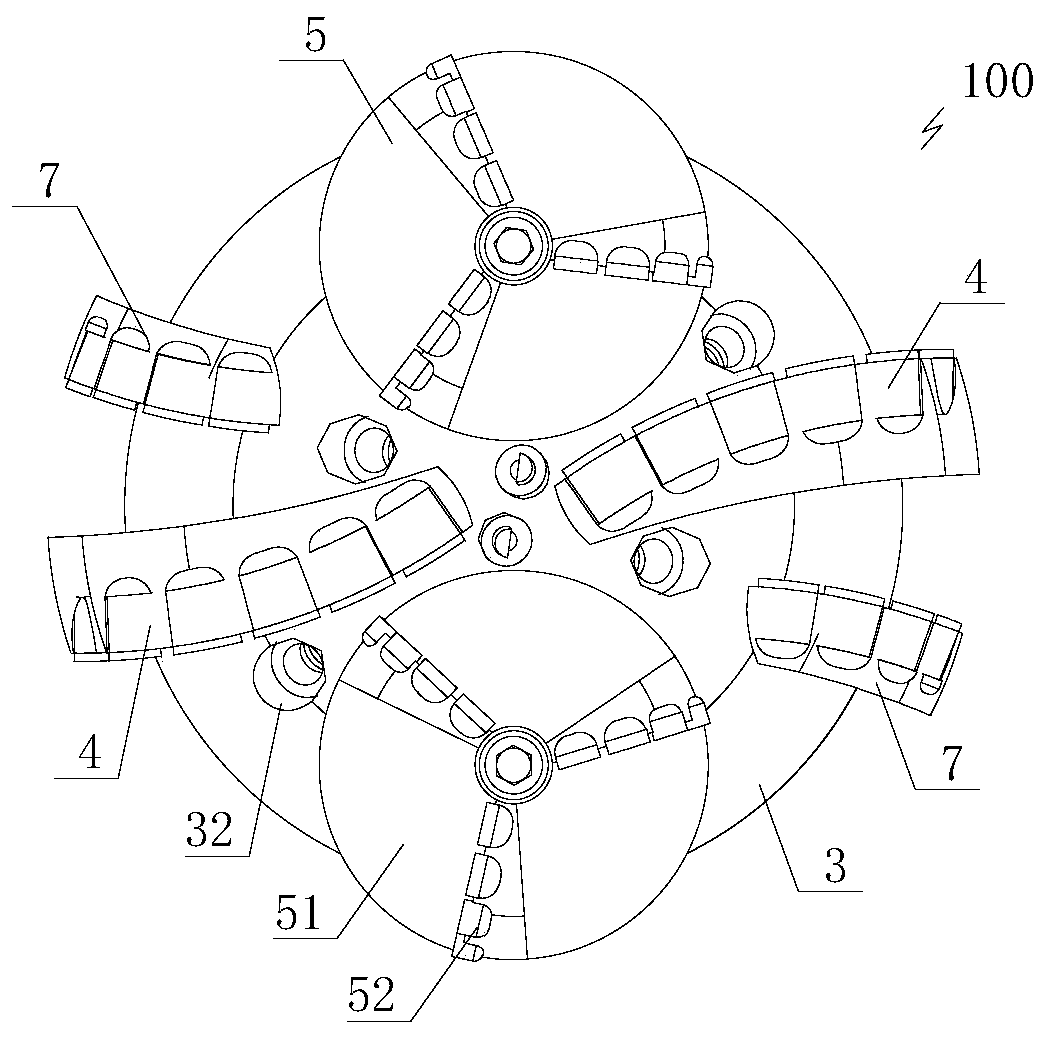

[0038] like Figure 1 to Figure 7 As shown, the present invention provides a composite rotary cutting PDC drill bit 100, which includes a hollow and fixed body upper shell 1, and the body upper shell 1 is rotated from top to bottom to connect the drill joint 2. In the embodiment, the drill joint 2 is located above the body upper casing 1 and a tapered thread portion 25 is provided, and the drill tool joint 2 is connected with the upper drill pipe through the tapered thread portion 25; the lower rotating sleeve of the body upper casing 1 is equipped with a The lower shell 3 of the main body which rotates synchronously with the tool joint 2, the sealing ring is realized between the upper shell 1 of the main body and the lower shell...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com