Mechanical coiling longitudinally wrapping paper tape device

A mechanical, paper tape technology, applied in electrical components, circuits, insulation of conductors/cables, etc., can solve the problems of unevenness, inconvenient construction, poor economy, etc., and achieve uniform and sufficient paper wrapping, convenient construction, and less consumables. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

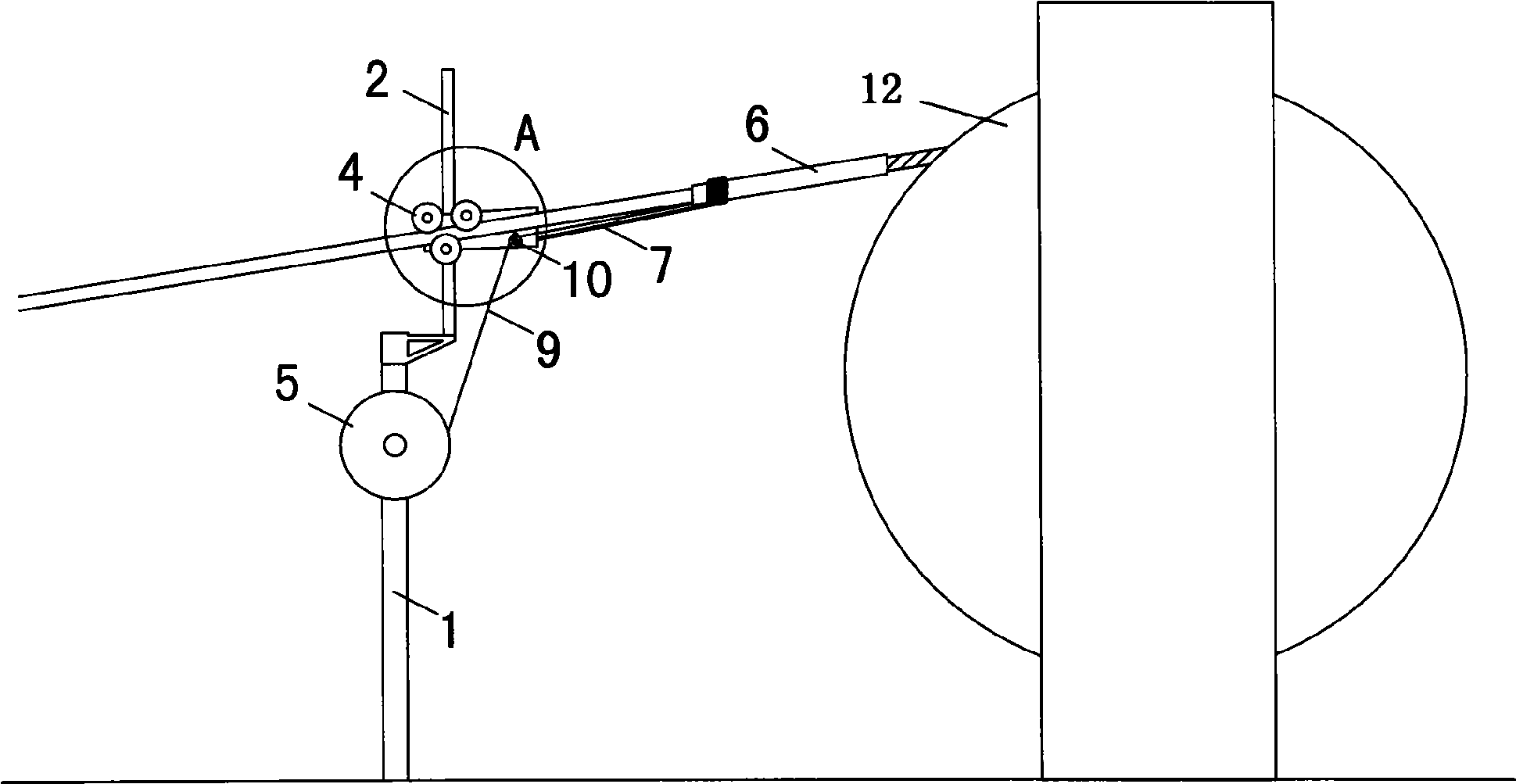

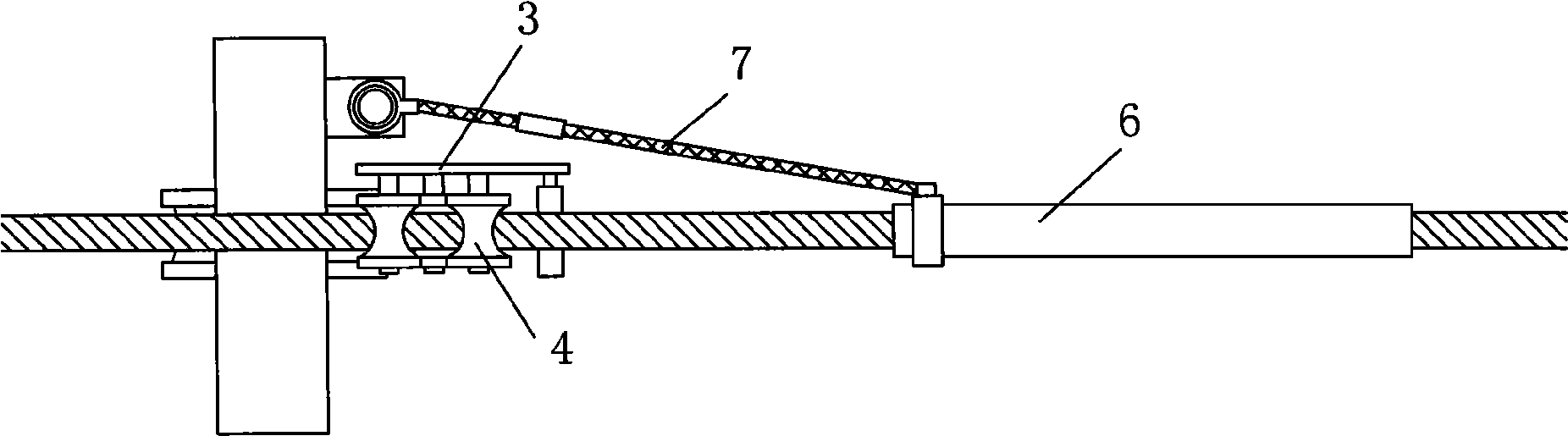

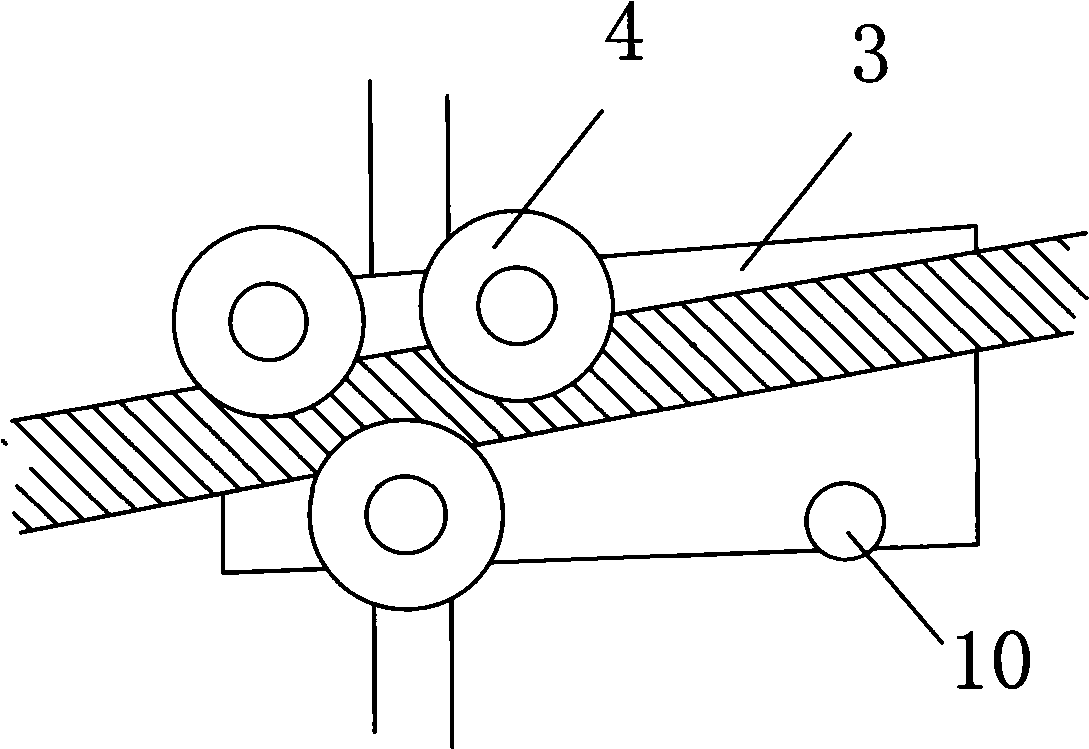

[0013] Such as Figure 1-Figure 4 As shown, a mechanical wire take-up longitudinal wrapping paper tape device according to the present invention includes a bracket 1, a slide bar 2, a mounting seat 3, a pressing wheel set 4, a paper tray 5, a sleeve guide 6, and a connecting rod 7. The slider regulator 8 and the paper tape limit wheel 10, the slider 2 is installed on the upper end of the bracket 1 fixed on the ground, the slider 2 passes through the slider regulator 8 on the back of the mounting seat 3, and the mounting seat 3 passes through the slider The adjuster 8 can slide freely along the vertical direction of the slide bar 2; during work, the pinch wheel set 4 suspended and rolled on the wire is arranged on the mounting seat 3, and the pinch wheel set 4 includes two upper wheels and one lower wheel. The sleeve guide 6 is set on the wire behind the pressing wheel 4, and is rigidly connected with the mounting seat 1 or the sliding rod adjustment seat 8 through the connecti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com