Zoom lens system, optical equipment and method for manufacturing zoom lens system

A technology of variable magnification lens and manufacturing method, applied in optics, optical components, instruments, etc., can solve problems such as inability to achieve optical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 2 approach

[0220] A preferred second embodiment of the present invention will be described below with reference to the drawings. In this specification, unless otherwise specified, the wide-angle end state and the telephoto end state refer to the state in the infinity focus state. Such as Figure 23 As shown, the variable power lens system ZL includes in order from the object side along the optical axis: the first lens group G1 with positive refractive power, the second lens group G2 with negative refractive power, the third lens group G3 with positive refractive power, and the third lens group G3 with positive refractive power. The fourth lens group G4 with negative refractive power, and the fifth lens group G5 with positive refractive power. When changing the magnification from the wide-angle end state to the telephoto end state, the distance between the first lens group G1 and the second lens group G2 changes, the distance between the second lens group G2 and the third lens group G3 c...

no. 1 example

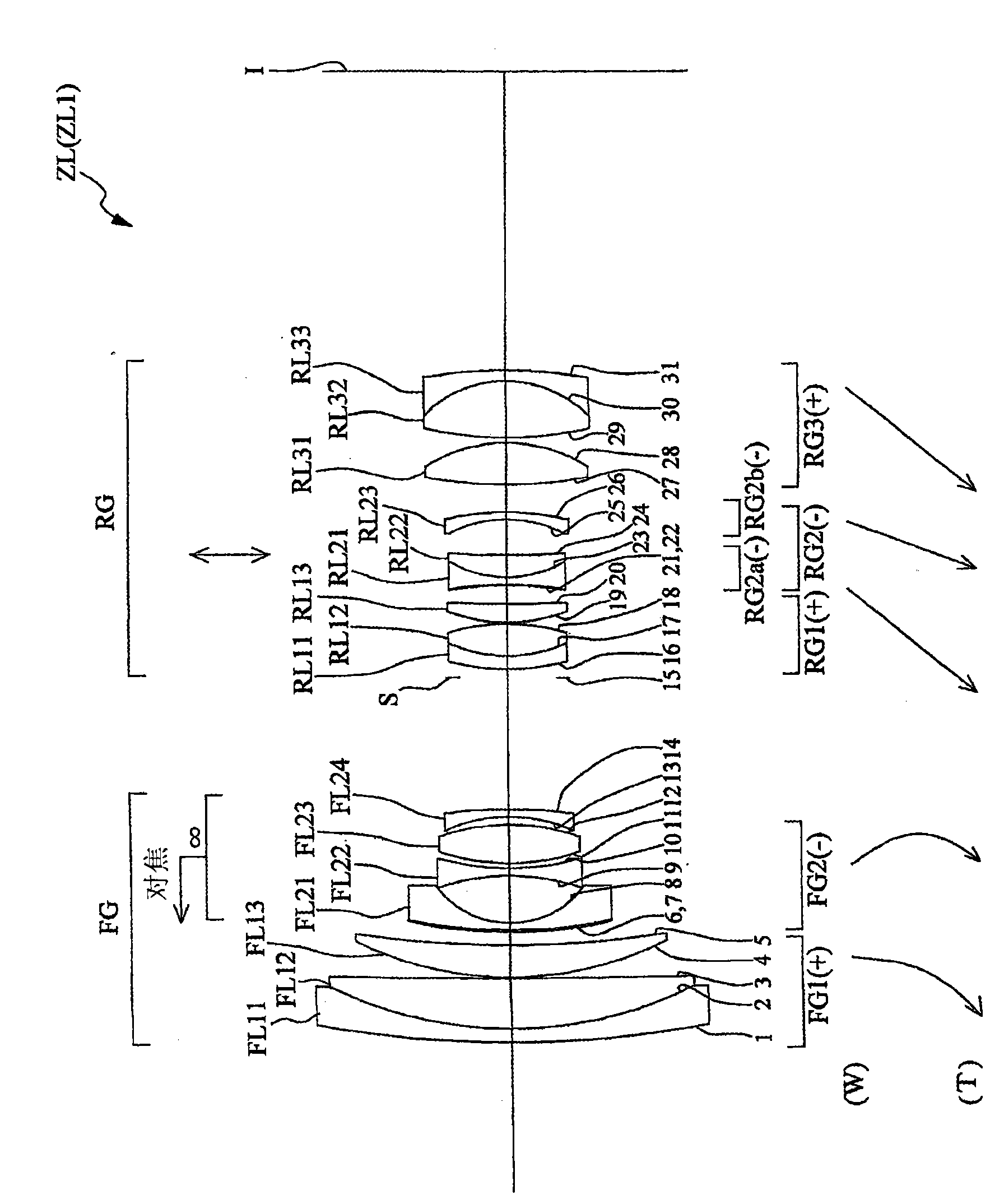

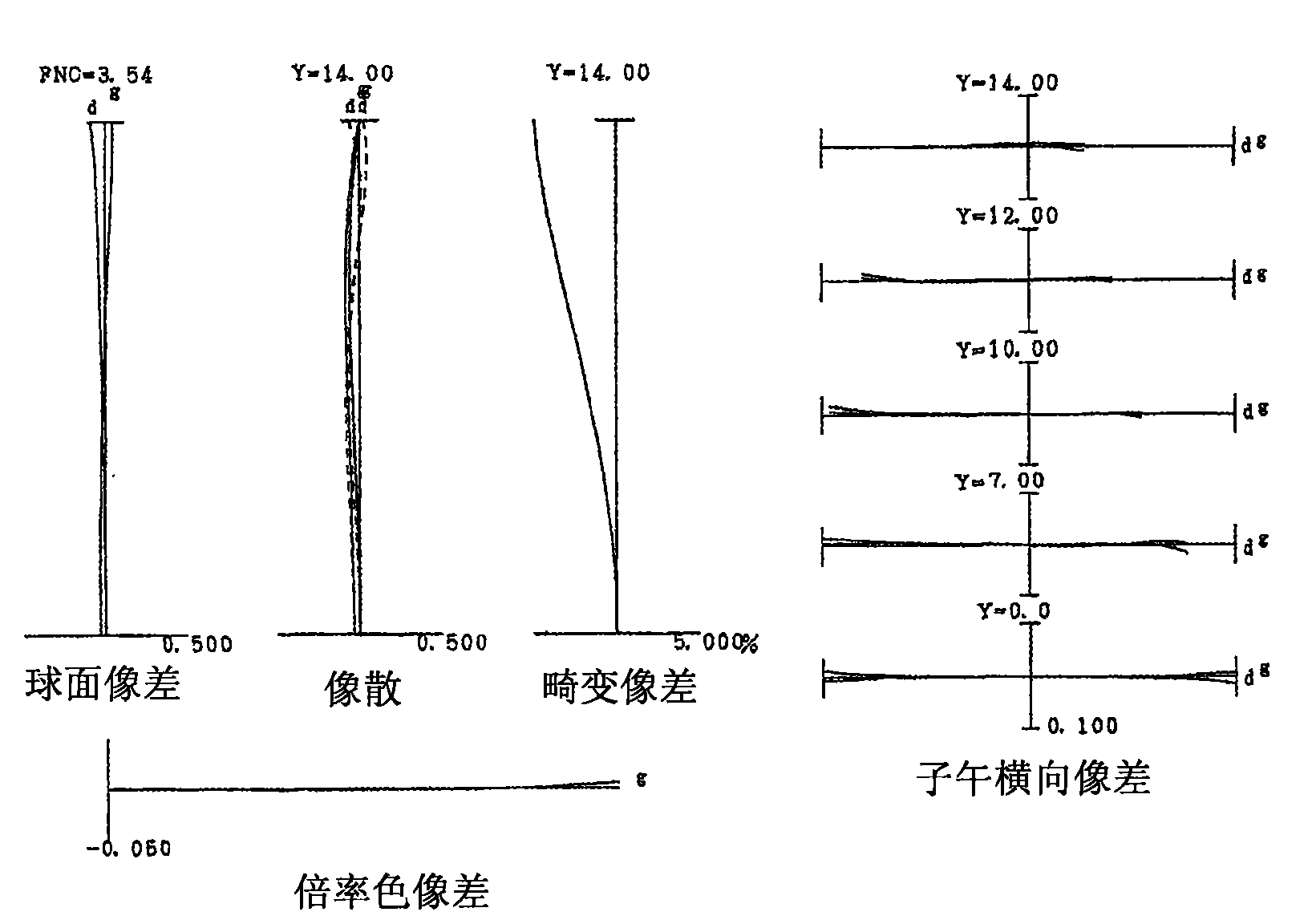

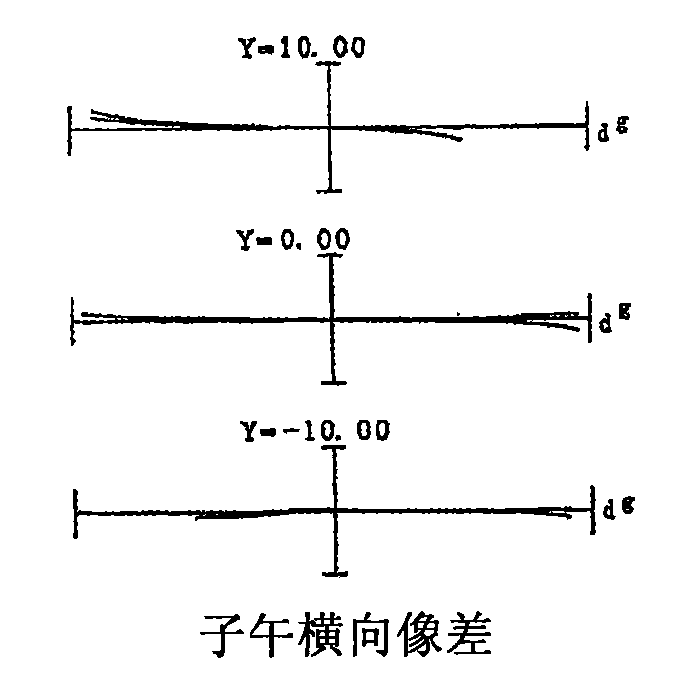

[0275] figure 1 It is a diagram showing the configuration of the variable power lens system ZL1 of the first embodiment. Should figure 1 The variable magnification lens system ZL1 includes in order from the object side: the front part lens group FG1 with positive refractive power; the rear part lens group FG2 with negative refractive power; the first lens group RG1 with positive refractive power; the part 2a with negative refractive power The lens group RG2a; the 2b portion lens group RG2b having a negative refractive power; and the third lens group RG3 having a positive refractive power. In the variable power lens system ZL1, when the lens position changes from the wide-angle end state to the telephoto end state, the air gap between the front part lens group FG1 and the rear part lens group FG2 changes, and the rear part lens group FG2 and the first lens group RG1 The air interval of the first lens group RG1 and the second part lens group RG2a is changed (increased) from d1...

no. 2 example

[0372] Figure 5 It is a figure which shows the structure of the variable power lens system ZL2 of 2nd Example. Should Figure 5 The variable magnification lens system ZL2 includes, in order from the object side: the front part lens group FG1 with positive refractive power; the rear part lens group FG2 with negative refractive power; the first lens group RG1 with positive refractive power; the part 2a with negative refractive power The lens group RG2a; the 2b portion lens group RG2b having a negative refractive power; and the third lens group RG3 having a positive refractive power. In this variable power lens system ZL2, when the lens position state changes from the wide-angle end state to the telephoto end state, the air gap between the front part lens group FG1 and the rear part lens group FG2 changes, and the rear part lens group FG2 and the first lens group RG1 The air interval of the first lens group RG1 and the second part lens group RG2a is increased from d12w to d12t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com