Novel mill sound device with frequency selection method

A grinding sound, a new technology, applied in the direction of measuring devices, electrical devices, instruments, etc., can solve the problems of low sensitivity, reduced measurement accuracy, and reduced resolution, and achieve the effect of high sensitivity and high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

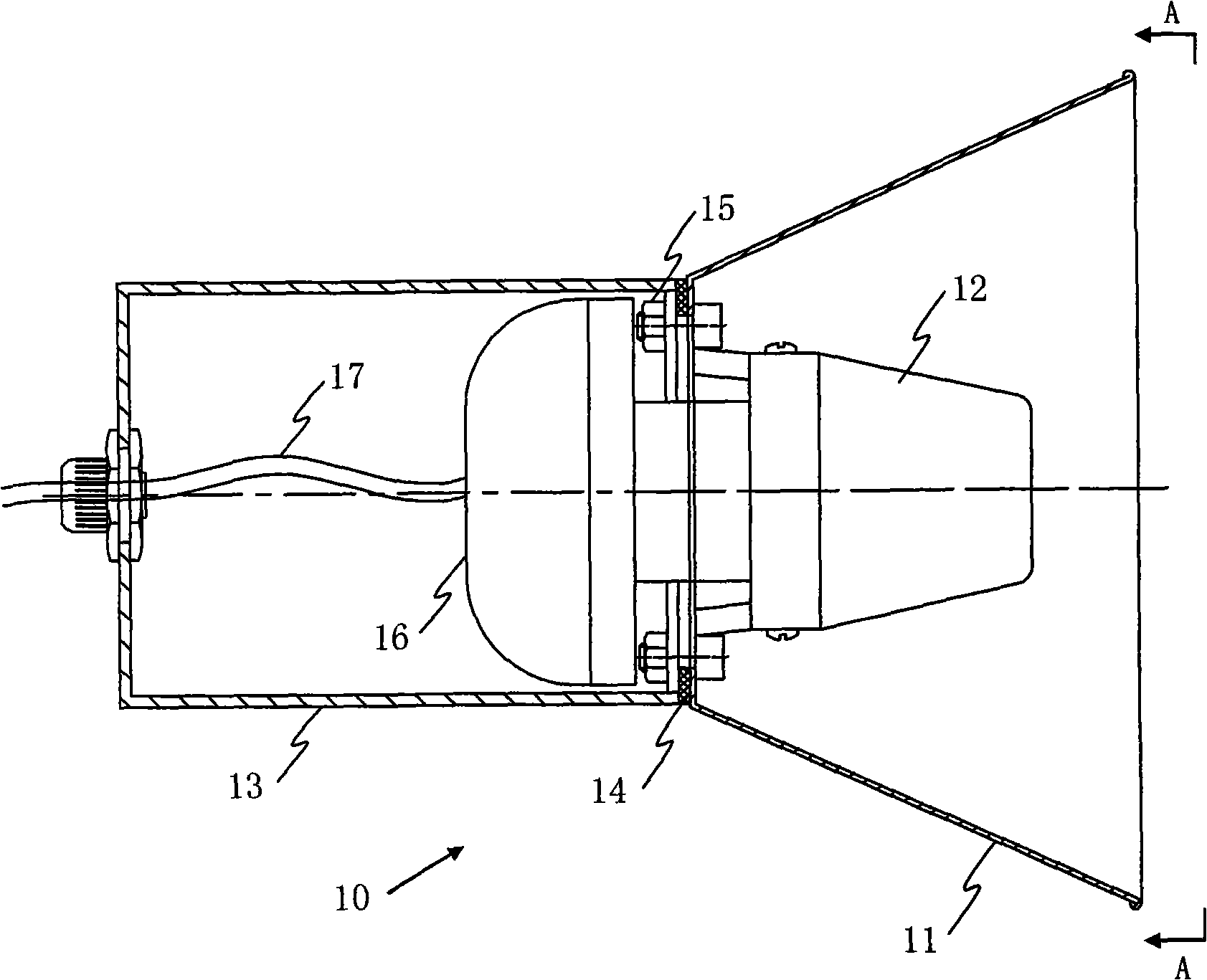

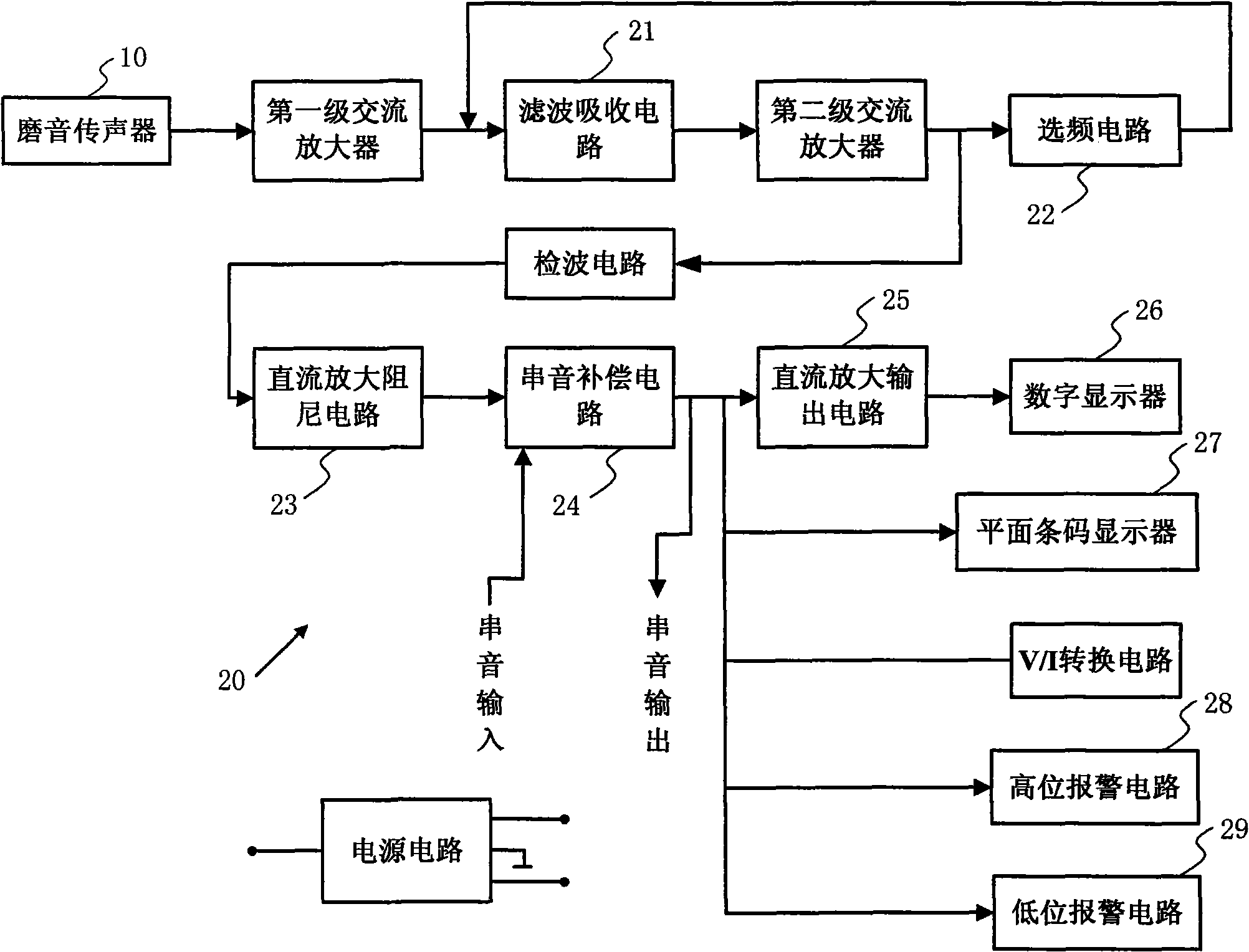

[0010] A new grinding sound device through frequency selection, the device includes a grinding sound microphone 10, the output end of the grinding sound microphone 10 is connected to a measurement circuit 20 through a cable 17 drawn from it, and a frequency selection circuit is set inside the measurement circuit 20.

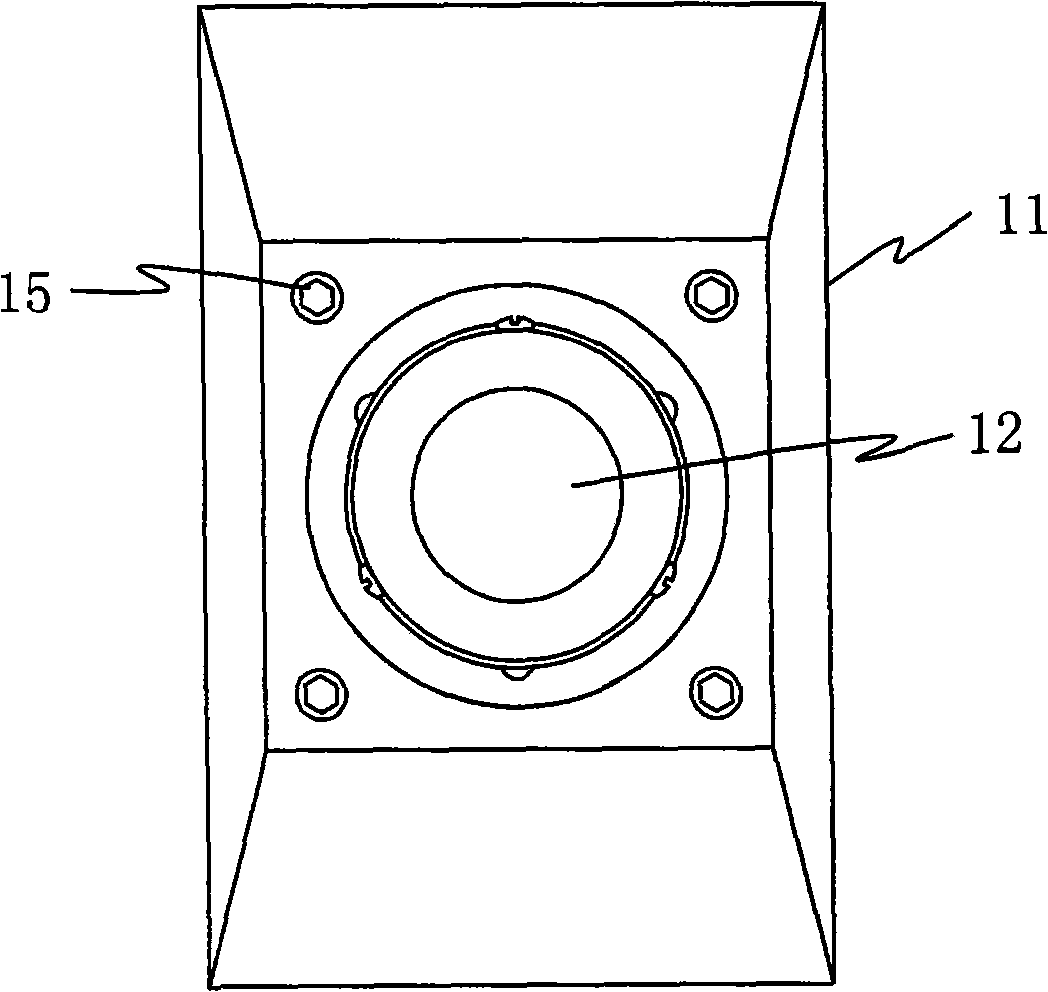

[0011] combine figure 1 , 2 , the head of the grinding sound microphone 10 is a square bell mouth 11, which replaces the original horn-type horn, and overcomes the shortcoming of poor directivity. Tweeter head 12 is fixed at the central position inside square bell mouth 11, and is used for concentrating the noise collected by square bell mouth 11, and sealing gasket 14 is arranged between square bell mouth 11 and shell 13, and square bell mouth 11 and shell 13 pass screw 15 The connection is fixed, the airtightness is good, and it can be dustproof and waterproof. The outer casing 13 is provided with an inner casing 16 , and the inner casing 16 is provided with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com