Safety detecting method for flue gas waste heat recovery power system of industrial furnace

A flue gas waste heat and power system technology, applied in furnaces, measuring devices, furnace components, etc., can solve problems such as leakage of power station boilers, prevent the expansion of accidents, shorten emergency repair cycles, and facilitate safe and economical operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

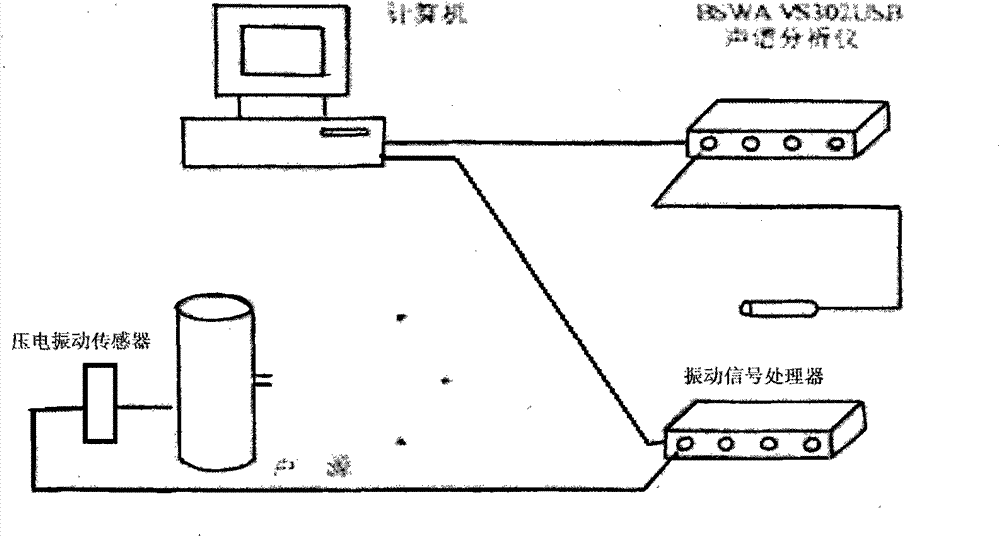

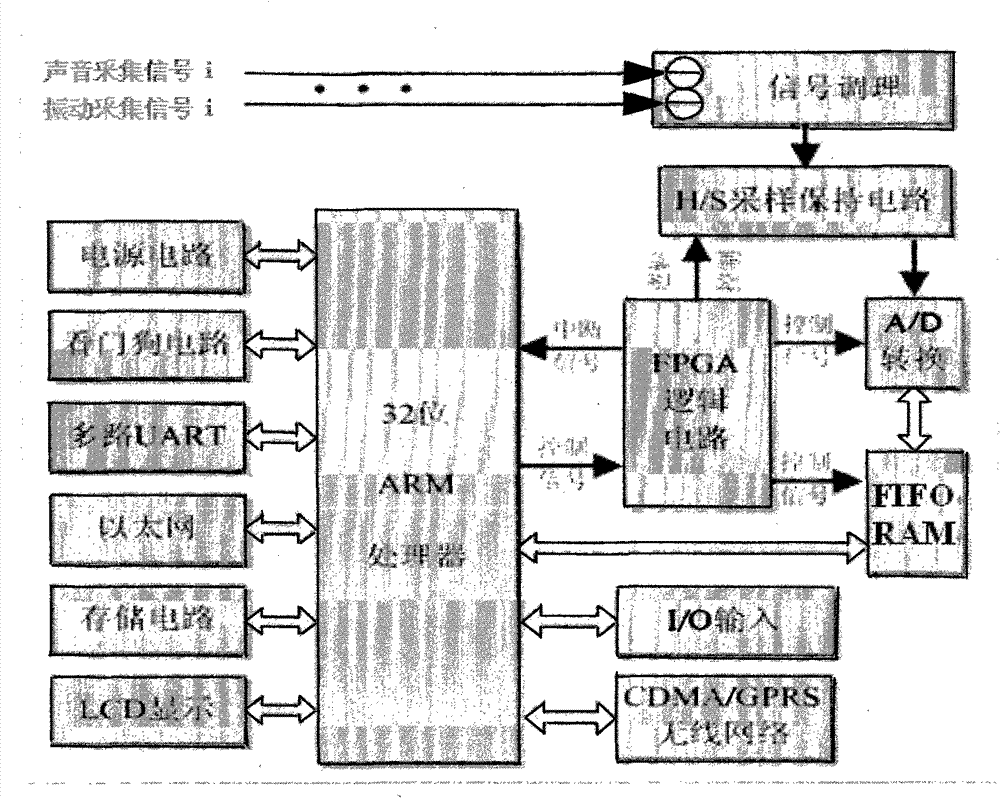

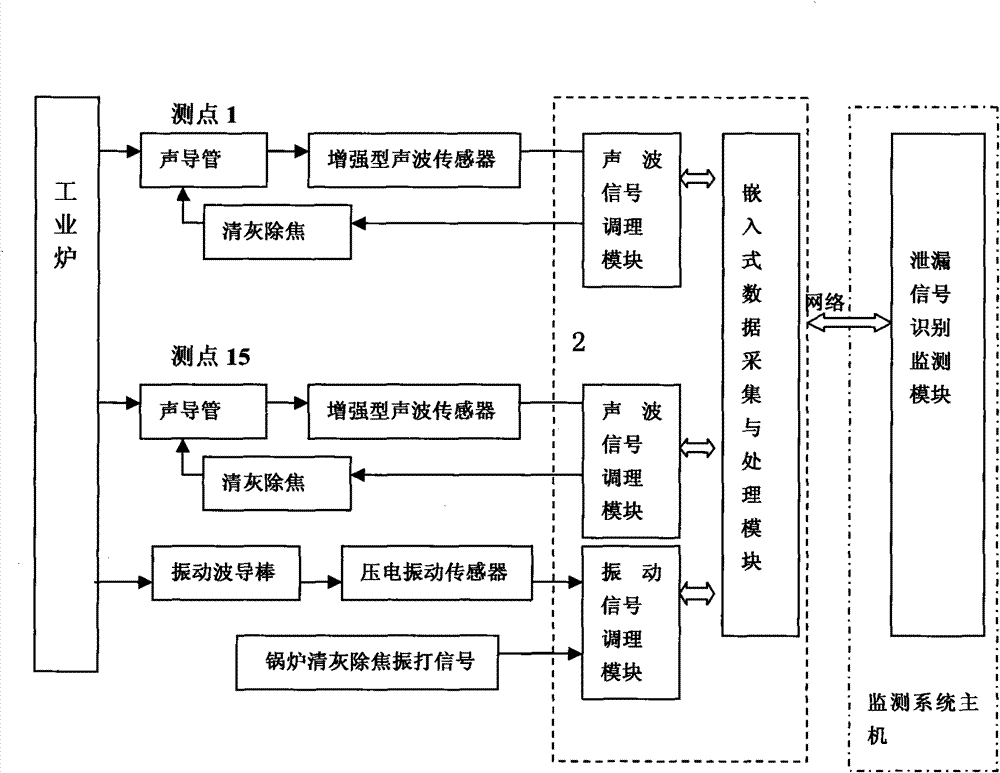

[0035] A metallurgical enterprise carried out necessary new safety inspections for the power system of industrial furnace flue gas waste heat recovery. Holes were opened on the fins between the furnace tubes on each heating surface of the boiler. Between the furnace tubes and the header, the enhanced acoustic wave sensor is installed at the other end of the acoustic waveguide to receive the noise signal from the furnace through the waveguide. When the pipeline in the furnace leaks, the high-temperature and high-pressure medium in the tube is ejected through cracks or breaches, generating noise with a wide frequency band, which spreads along the air and metal pipelines. At the same time, the normal operation of industrial furnaces produces quite strong background noise. The sensor collects all the on-site sound data in the receiving furnace, converts it into a current signal through the preamplifier, and transmits the current signal to the embedded data acquisition and processi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com