Particle or aerosol gathering unit of office machine

A technology for collecting devices and particles, used in printing devices, instruments, electrographics, etc., to solve the problems of inability to collect or remove inkjet aerosols or particles, and inability to absorb paper dust.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

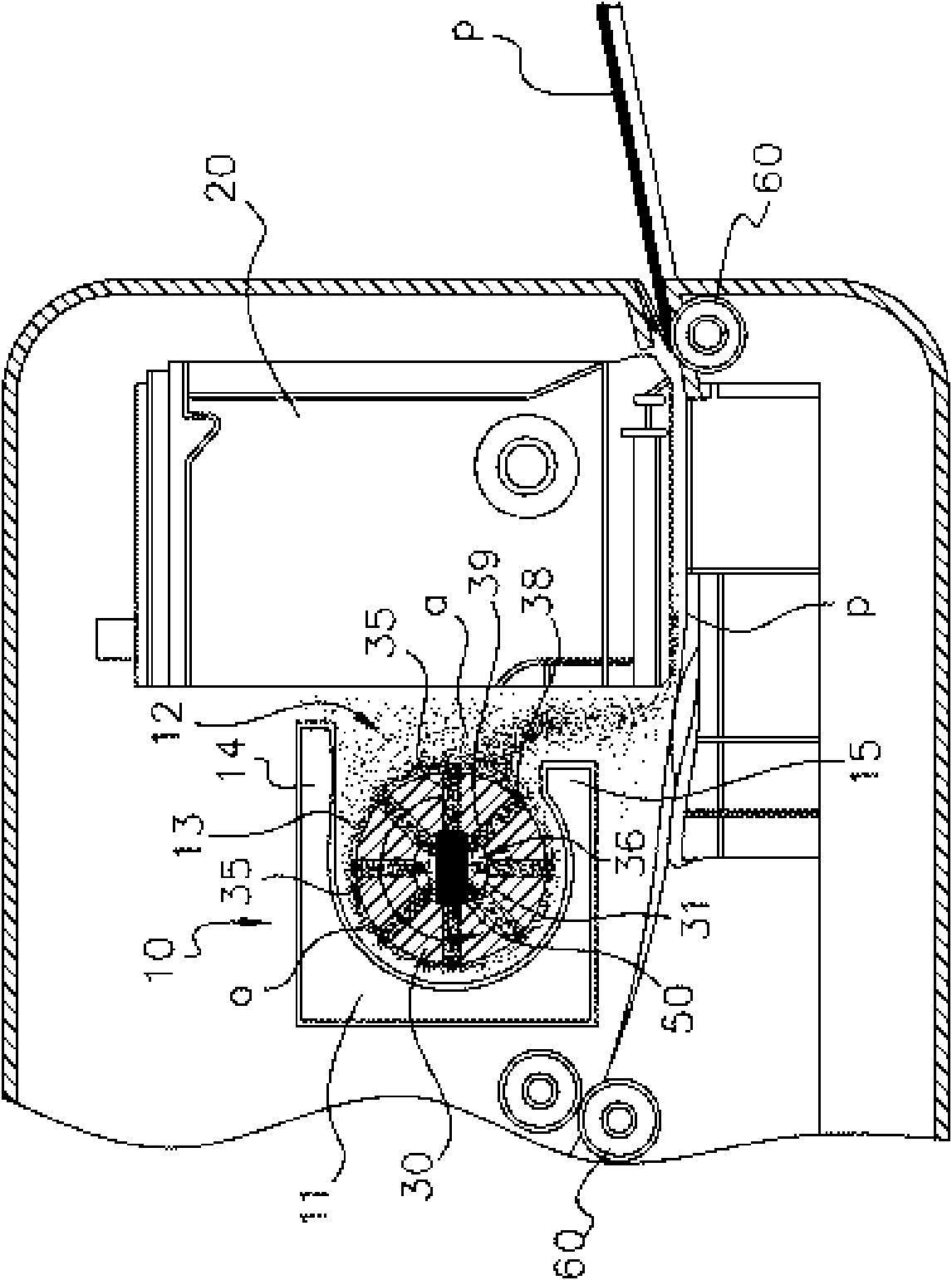

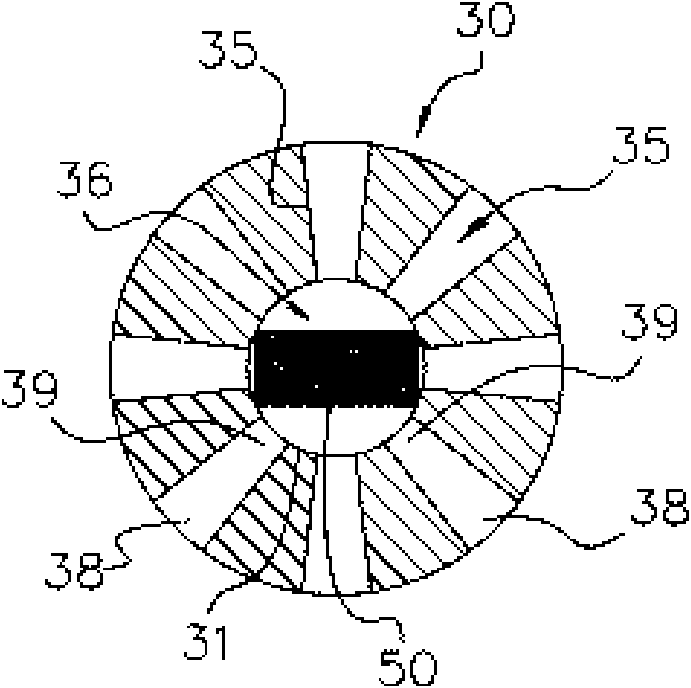

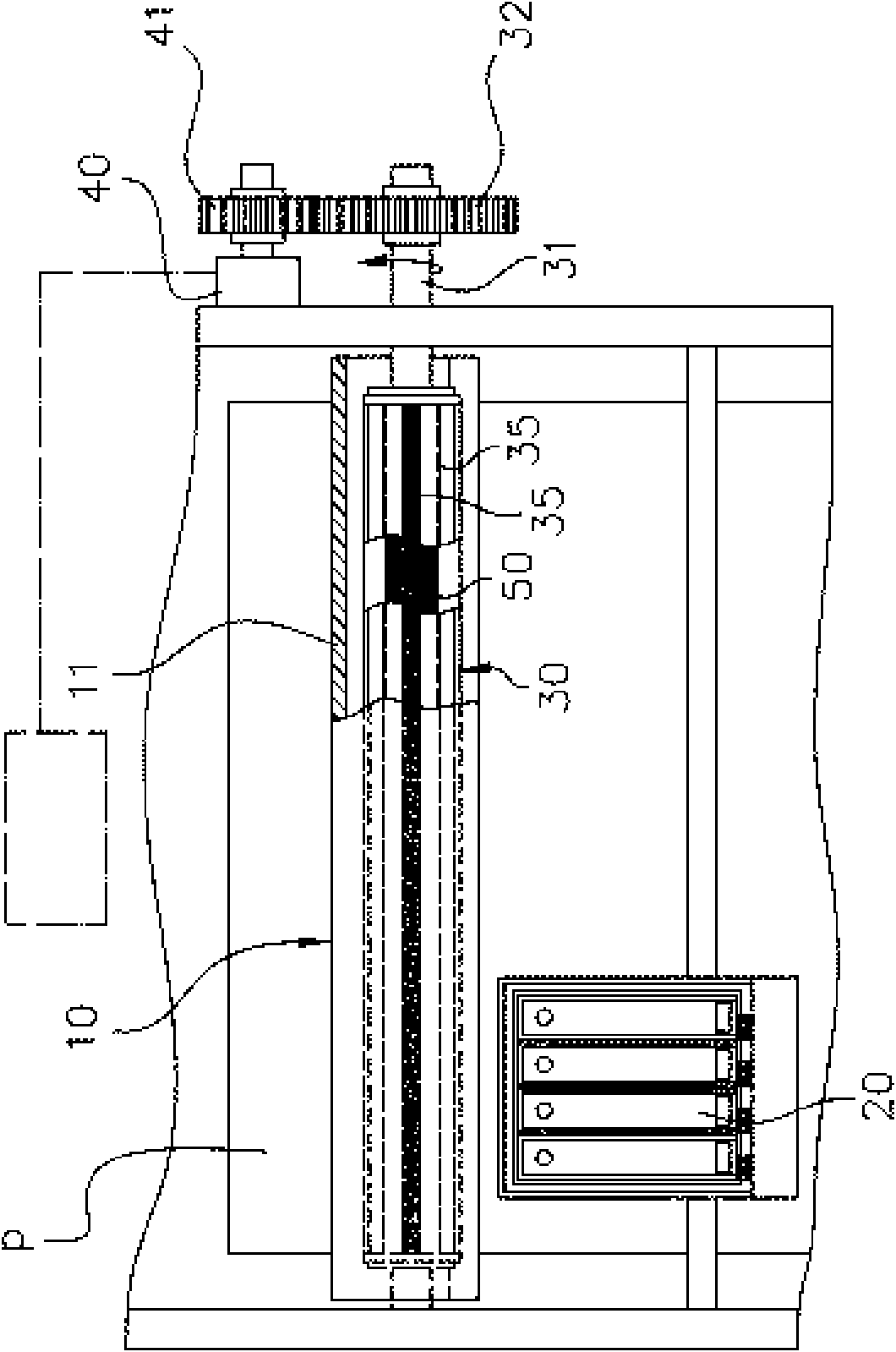

[0032] see figure 1 , figure 2 and image 3 , the present invention is a particle or aerosol collection device for an office machine, including a collection device, generally represented by reference number 10 . Said collecting device 10 is arranged on the position close to a printing part or printing head 20, comprises a housing 11 with opening 12; Housing 11 has an upper part 14 and lower part 15, and defines a space 13, configures an absorbing Part 30 is used to attract or collect particles or ink aerosols a that are scattered in the air.

[0033] Please refer to image 3 , the absorption part 30 is driven by a motor 40 and can rotate freely; and with the rotation of the absorption part 30, the air is brought into the absorption part 30, and a negative pressure effect is established in the vicinity of the absorption part 30 to guide or collect volatile Particles or ink aerosol a scattered in the air inside the business machine move to the absorbing portion 30 . In the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com