Shock resistant continuous measurement type shift contactor

A contactor and measurement technology, applied in the direction of switches, rails, electrical components, etc., can solve the problems of inability to give early warning, easy drop of shrapnel elasticity, and inability to ensure pressure on contacts, and achieves a convenient and timely treatment and improves seismic performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

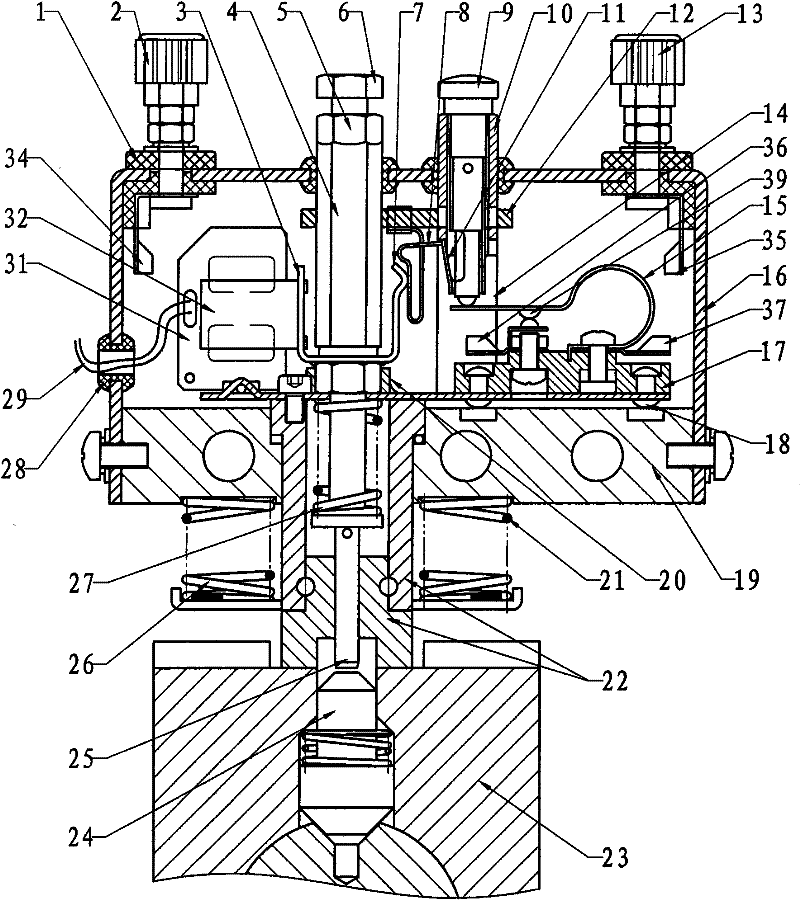

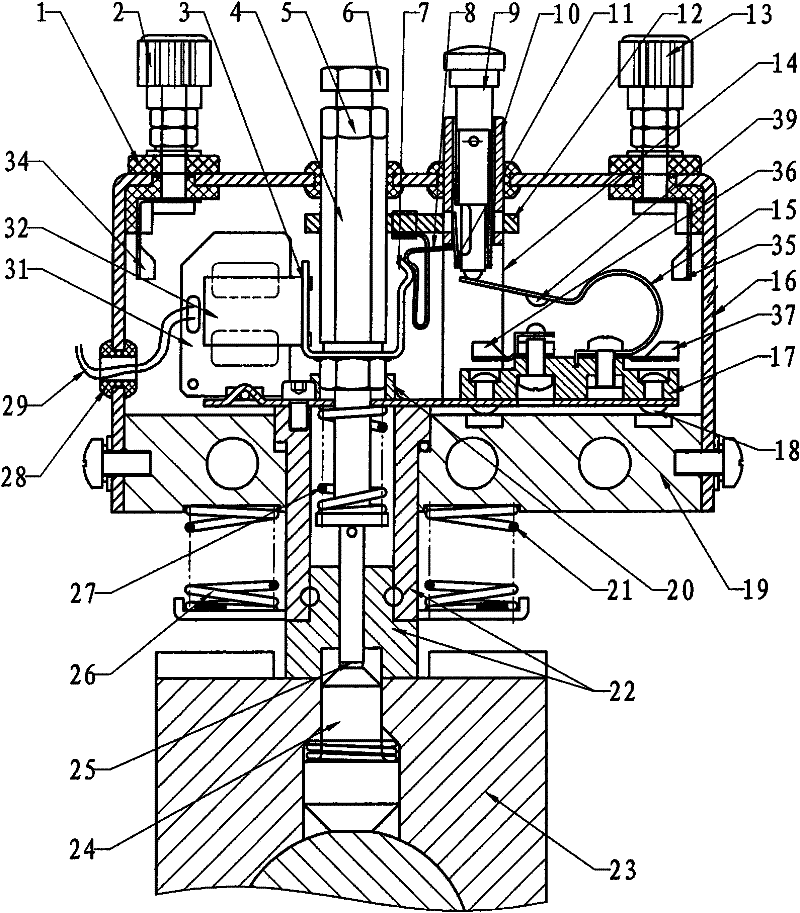

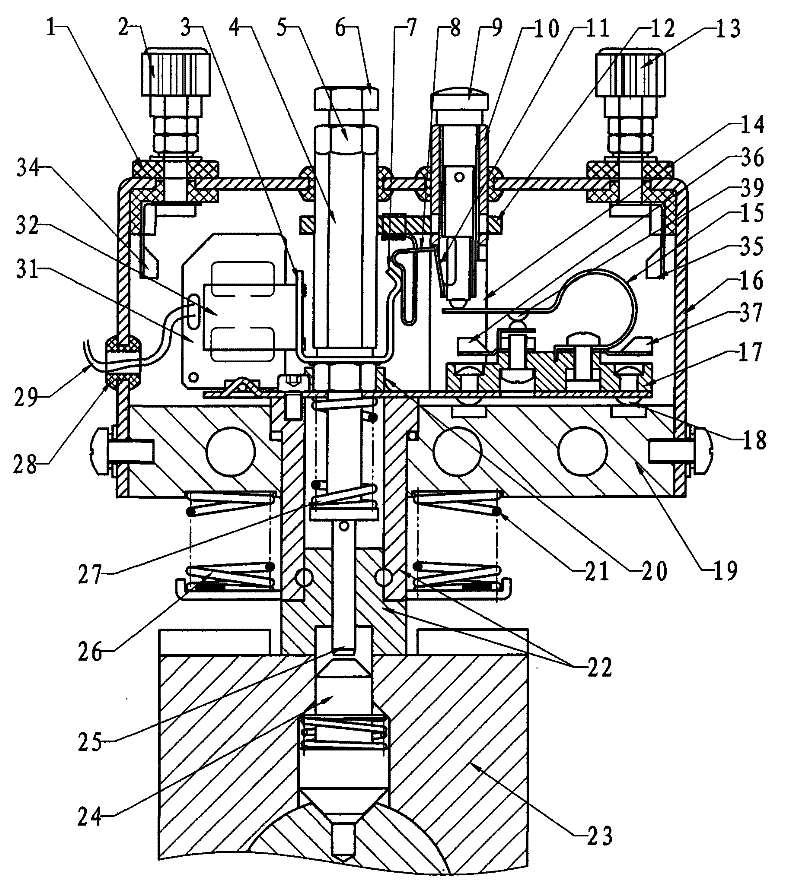

[0026] Such as figure 1 As shown, the displacement contactor includes a fixed base 19, a housing 16, a first terminal 2 indicating the circuit, a second terminal 13 indicating the circuit, a micro switch, a push rod 6, an upper adjustment cylinder 4, a lower adjustment cylinder 22 and The push rod moves down spring 27, the first integrally moved down spring 21, the second integrally moved down spring 26, and the eddy current displacement sensor.

[0027] The bottom of the shell 16 is fixed on the holder 19 with screws. A carrier plate 18 that can move up and down relative to the fixed seat is arranged on the fixed seat 19 .

[0028] The micro switch includes a first contact point 36 , a second contact point 37 , and a conductive shrapnel 15 with strong elastic force. The first contact 36 and the second contact 37 are respectively fixed on the insulating base 17 by screws, and the insulating base 17 is fixed on the carrier plate 18 . It shows that the first terminal 2 of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com