Fluid pump driven by compressed air

A technology of compressed air and fluid pumps, applied in the direction of pumps, piston pumps, machines/engines, etc., can solve problems such as difficulty, easy piston failure, maintenance and installation, etc., and achieve the effect of simple maintenance and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

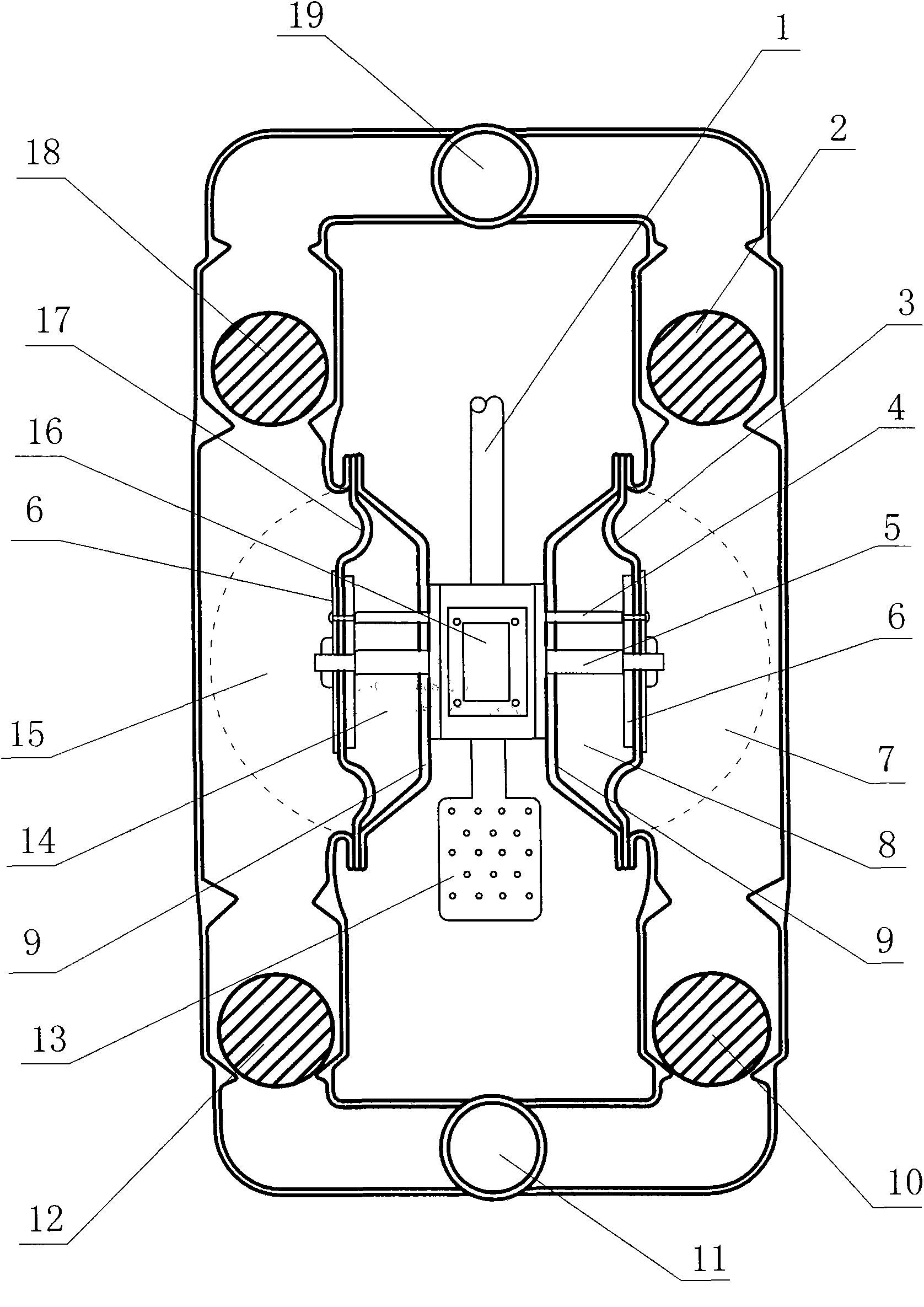

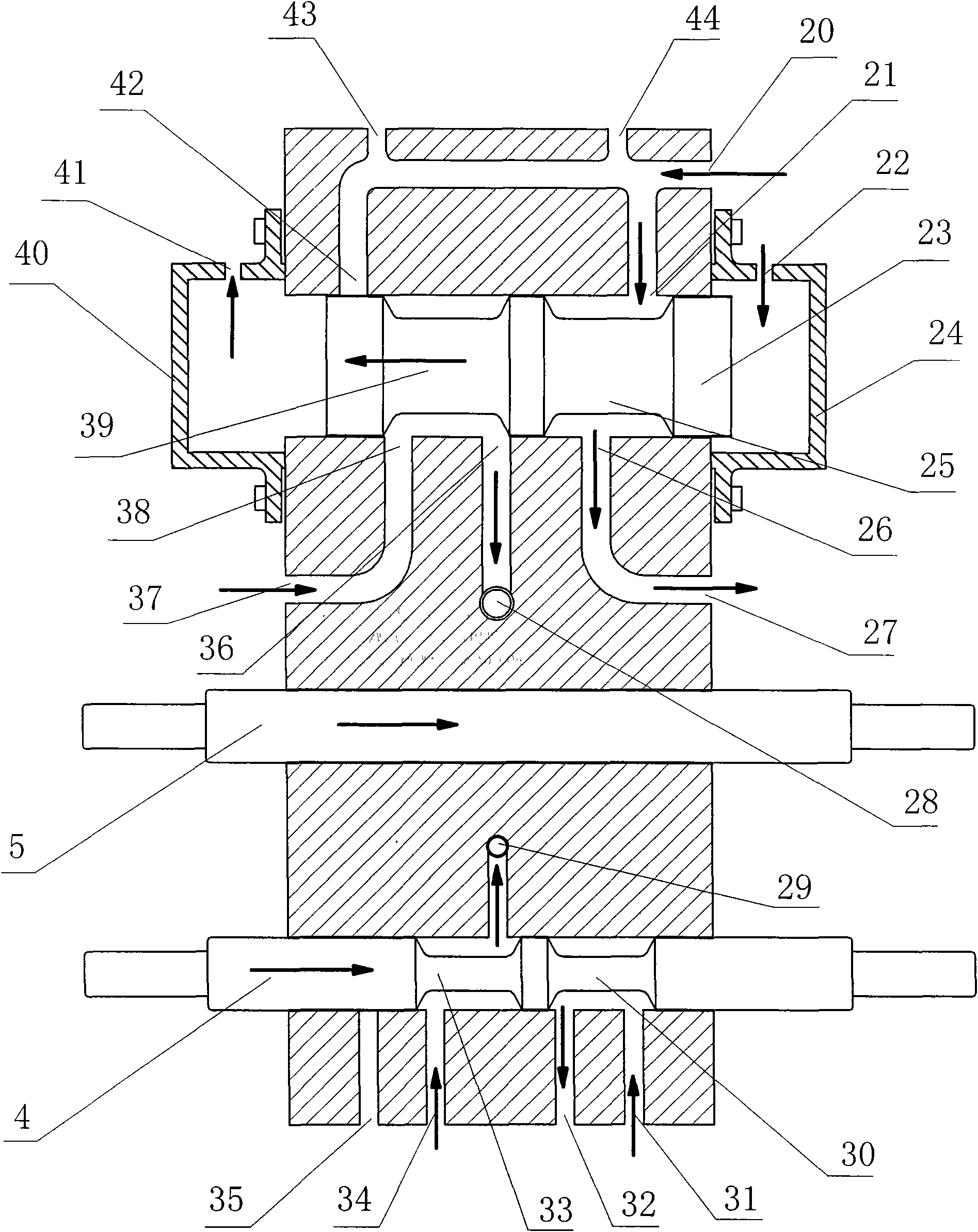

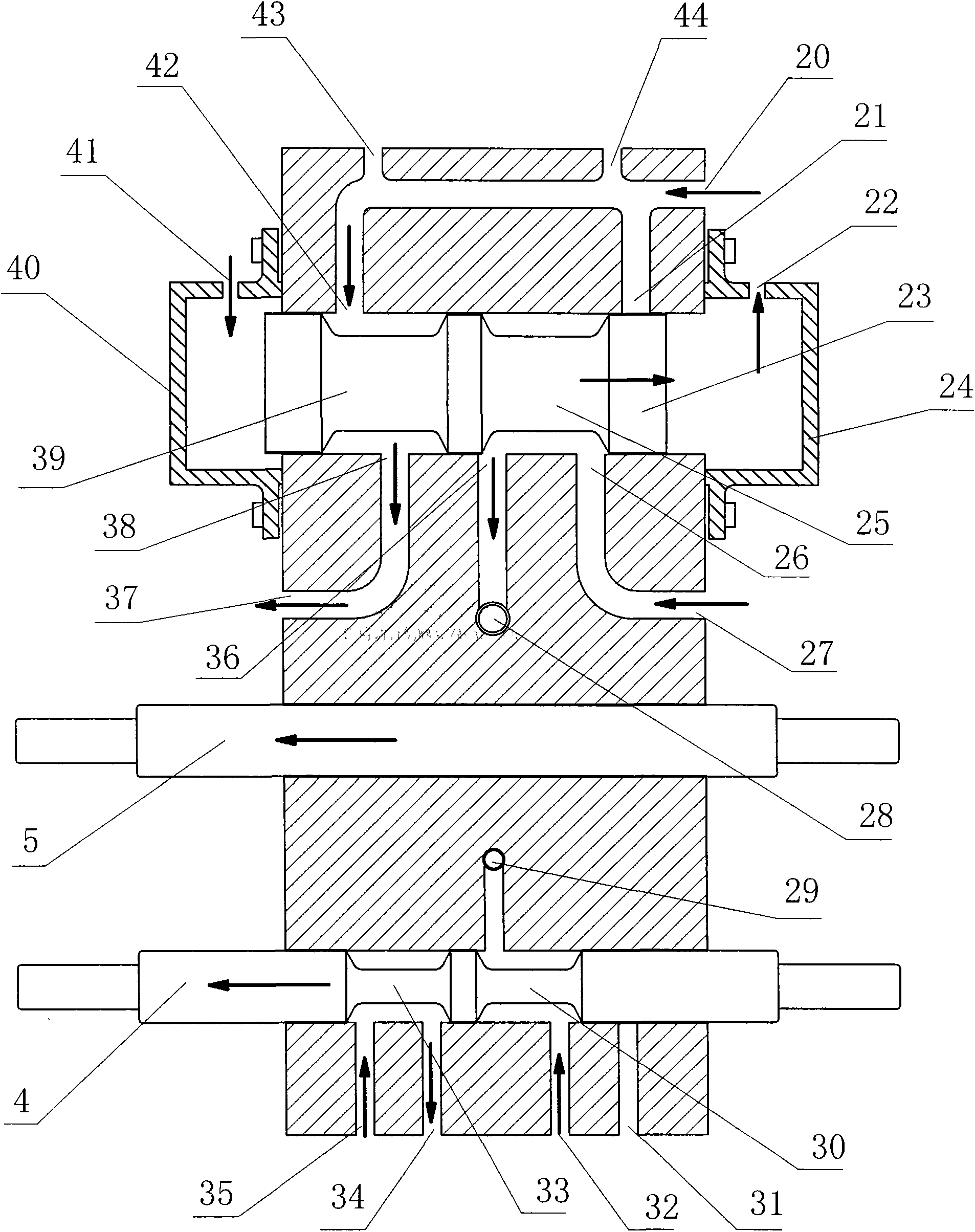

[0055] like figure 1 , figure 2 , image 3As shown, a fluid pump driven by compressed air includes a central body 16, a central shaft 5, a reversing shaft 4, a left diaphragm 17, a right diaphragm 3, a left air chamber 14, a right air chamber 8, and a left fluid chamber 15. Right fluid chamber 7, valve ball A18, valve ball B2, valve ball C12, valve ball D10, fluid inlet 11 and flow out 19, etc. The central shaft 5 and the reversing shaft 4 are movably installed on the central body 16, and a sealing ring is installed between the central shaft 5, the reversing shaft 4 and the central body 16, and the central shaft 5 and the reversing shaft 4 move left and right on the central body 16 air will not pass through. The left diaphragm 17 and the right diaphragm 3 are respectively installed at both ends of the central shaft 5, and the two diaphragms are fixed on both ends of the central shaft 5 through the diaphragm splint 6, and the two ends of the reversing shaft 4 are also respe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com