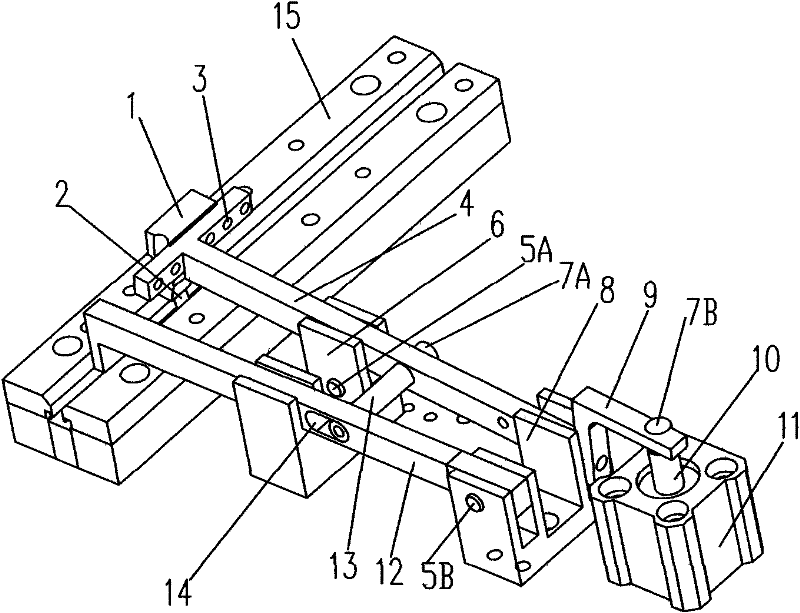

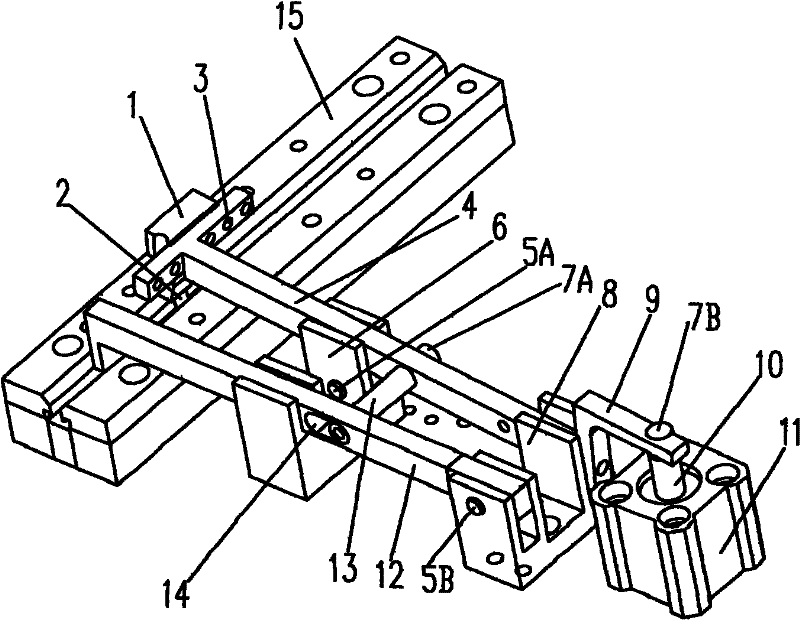

A sorting structure of integrated circuit testing and sorting machine

A technology for testing sorting machines and integrated circuits, applied in sorting and other directions, can solve problems such as high cost and short service life, and achieve the effects of eliminating shaking, facilitating maintenance and replacement, and reducing use costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] When the cylinder block 11 is working and the cylinder shaft 10 is jacked up, the front shift lever 4 is supported by the shift lever pin 5A as a fulcrum, and the part of the shift lever pin 5A side biased to the cylinder block 11 will be tilted with the cylinder shaft 10. The part of the other side of the gear lever pin 5A that is partial to the particle briquetting block 1 will descend to realize the function of the second-to-last grain; at the same time, the warping of the front gear lever 4 side will drive the warping of the optical axis 13 positioned above. Since the gear lever pin 5B as a fulcrum on the rear gear lever 12 is located on the rear support 8 at the tail, the optical axis 13 will move in the through groove 14 on the rear gear lever 12, and drive the rear gear lever 12 around the gear lever The pin 5B is tilted up to realize the function of putting the last material; similarly, when the cylinder shaft 10 is retracted downward, the front gear lever 4 is s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com