Lever bracket mechanism for reducing transmission backlash of gears

A technology of gear transmission and support mechanism, which is applied in the direction of gear transmission, transmission, belt/chain/gear, etc., which can solve the problems of difficult adjustment, difficulty in ensuring center distance accuracy, side clearance, and increase in backlash

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention is described in more detail below in conjunction with accompanying drawing example:

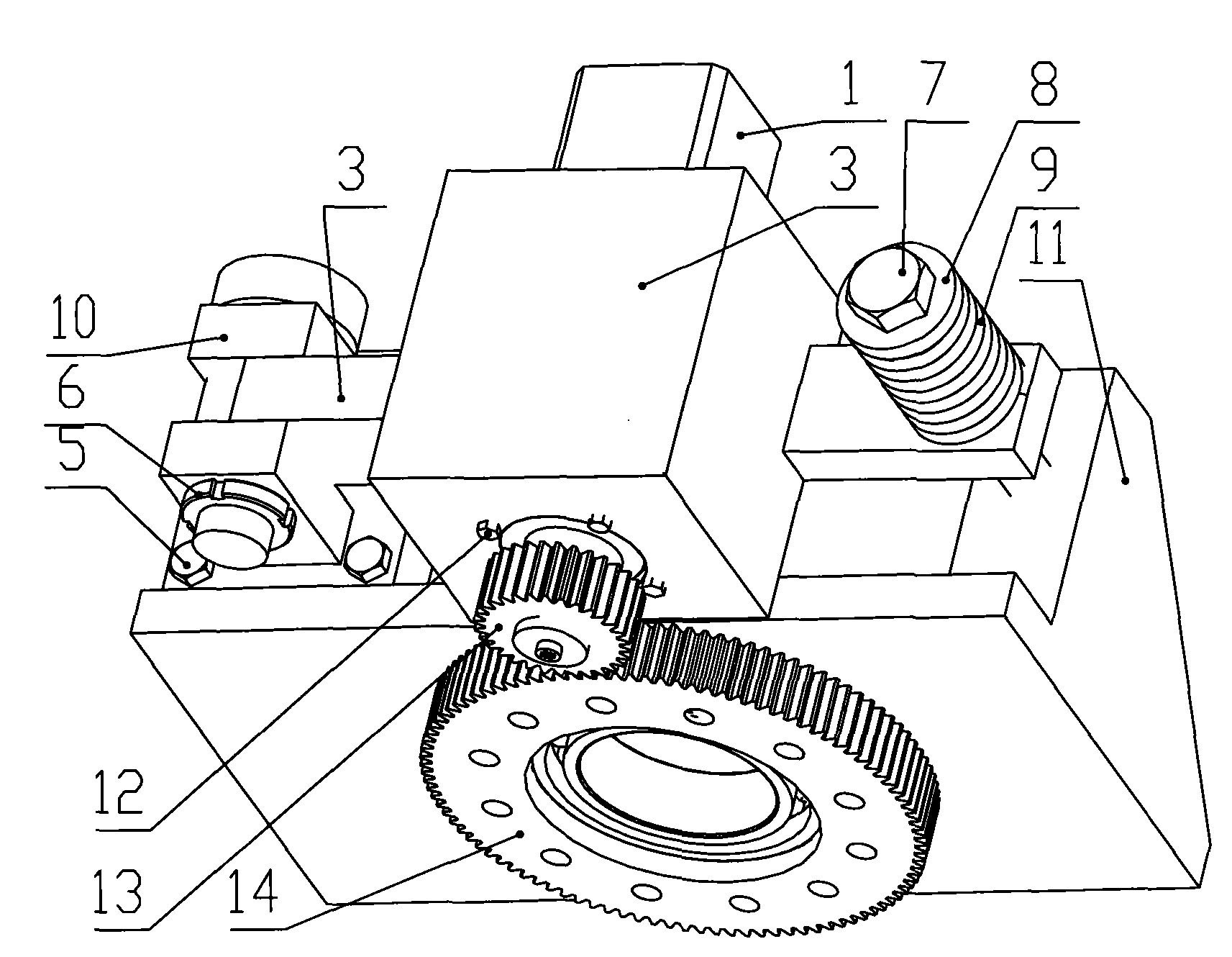

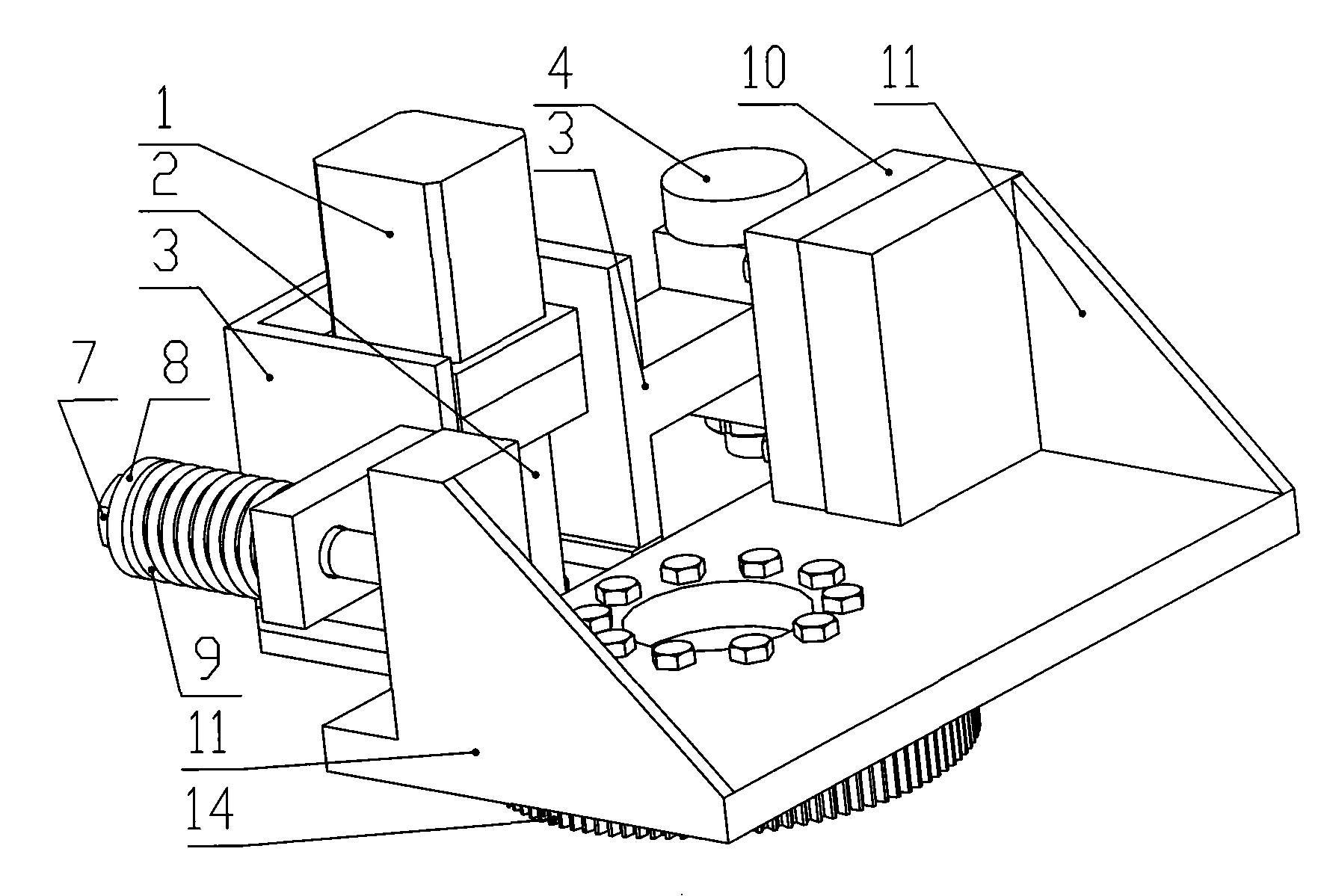

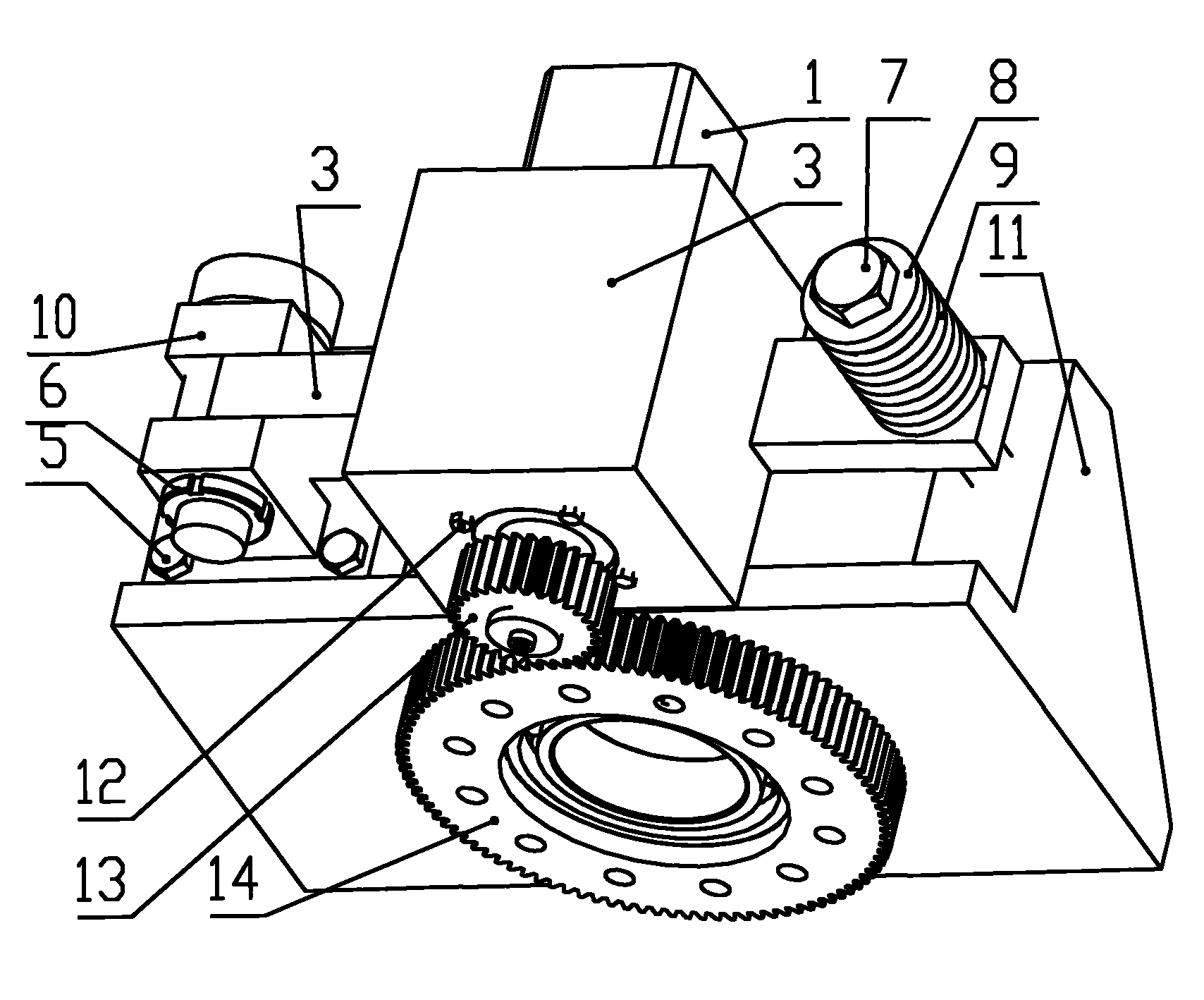

[0012] combine figure 1 with figure 2 The composition of the present invention includes: motor 1, reducer 2, lever bracket 3, pin shaft 4, screw group 5, small round nut 6, bolt 7, guide plate 8, compression spring 9, bracket 10, gear mounting body 11, Screw group 12, gear 13 and gear 14.

[0013] Fix the speed reducer 2 on the lever bracket 3 through the screw group 12, and then fix a gear 13 on the output shaft of the speed reducer 2; fix the bracket 10 on the gear mounting body 11 through the screw group 5, and process on the bracket 10 There is a hole, one end of the lever bracket 3 is processed with a hole, the pin shaft 4 passes through the above-mentioned hole, and the insertion end of the pin shaft 4 is screwed into the pin shaft 4 with a small round nut 6, and the pin shaft 4 is axially fixed, so that the lever bracket 3 can Rotate around the axis of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com