Molding machine

A molding and cavity technology, which is applied in the field of simultaneous molding of upper and lower boxless molds, can solve the problems of long time consumption and low mold production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

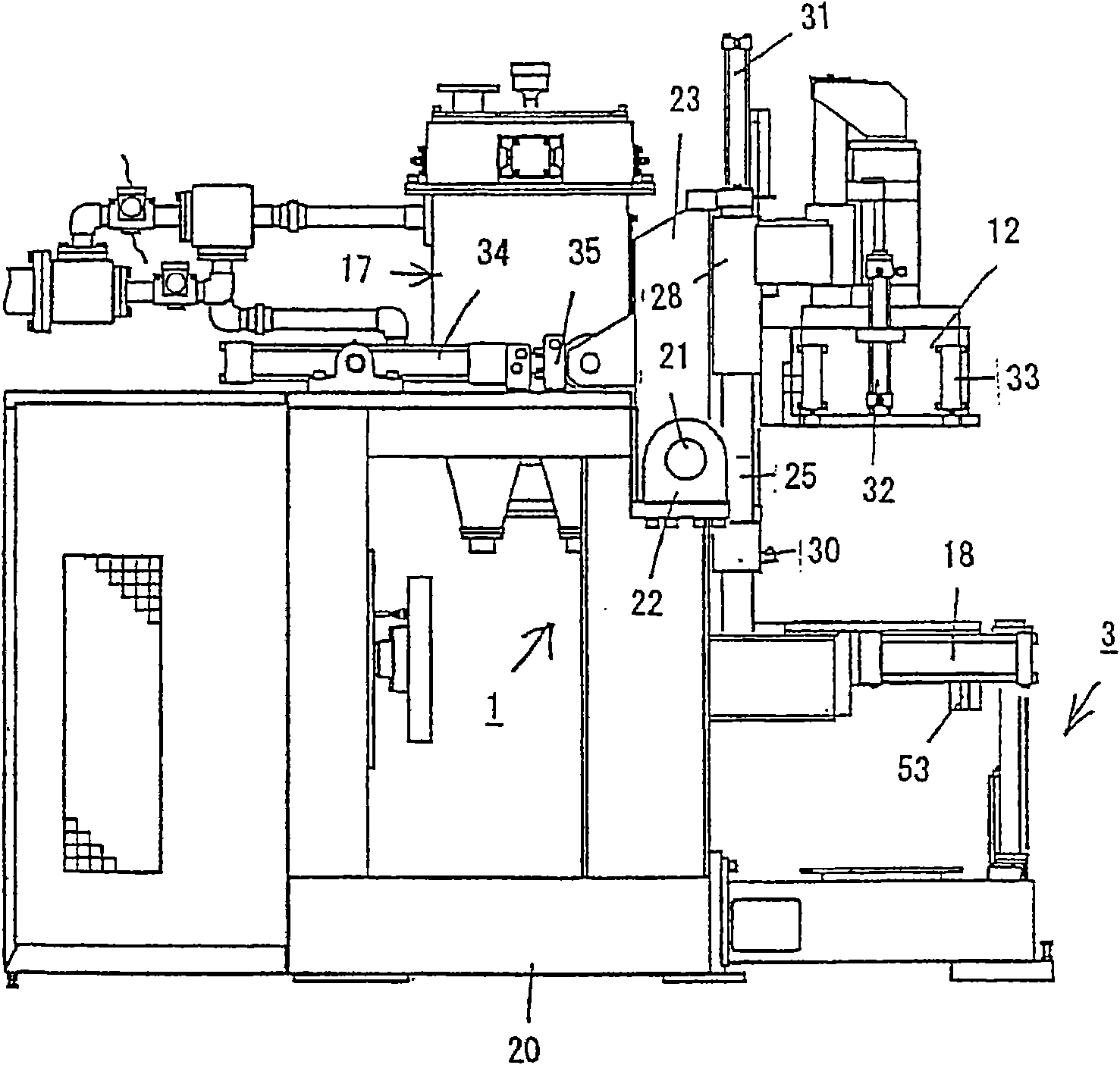

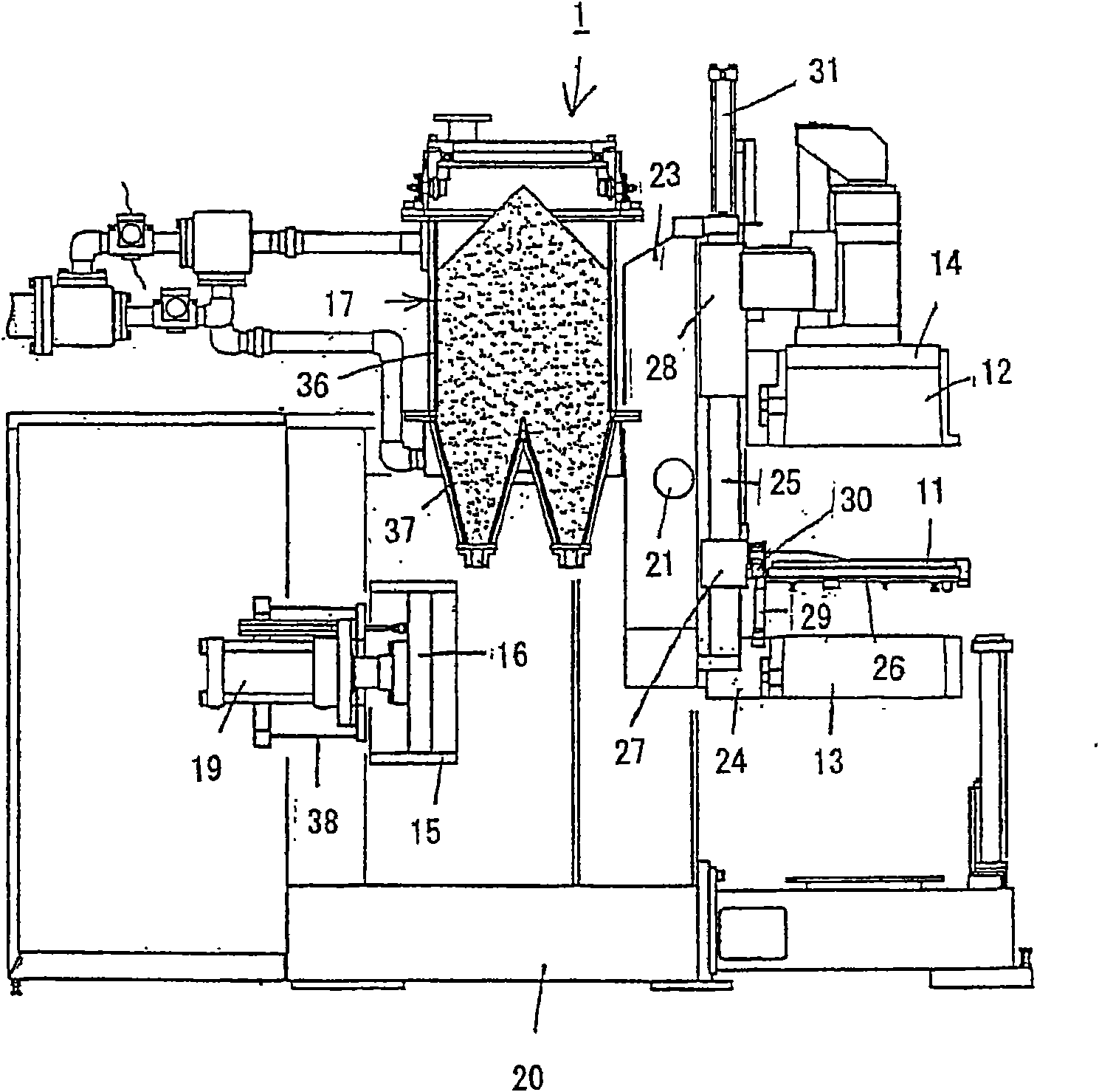

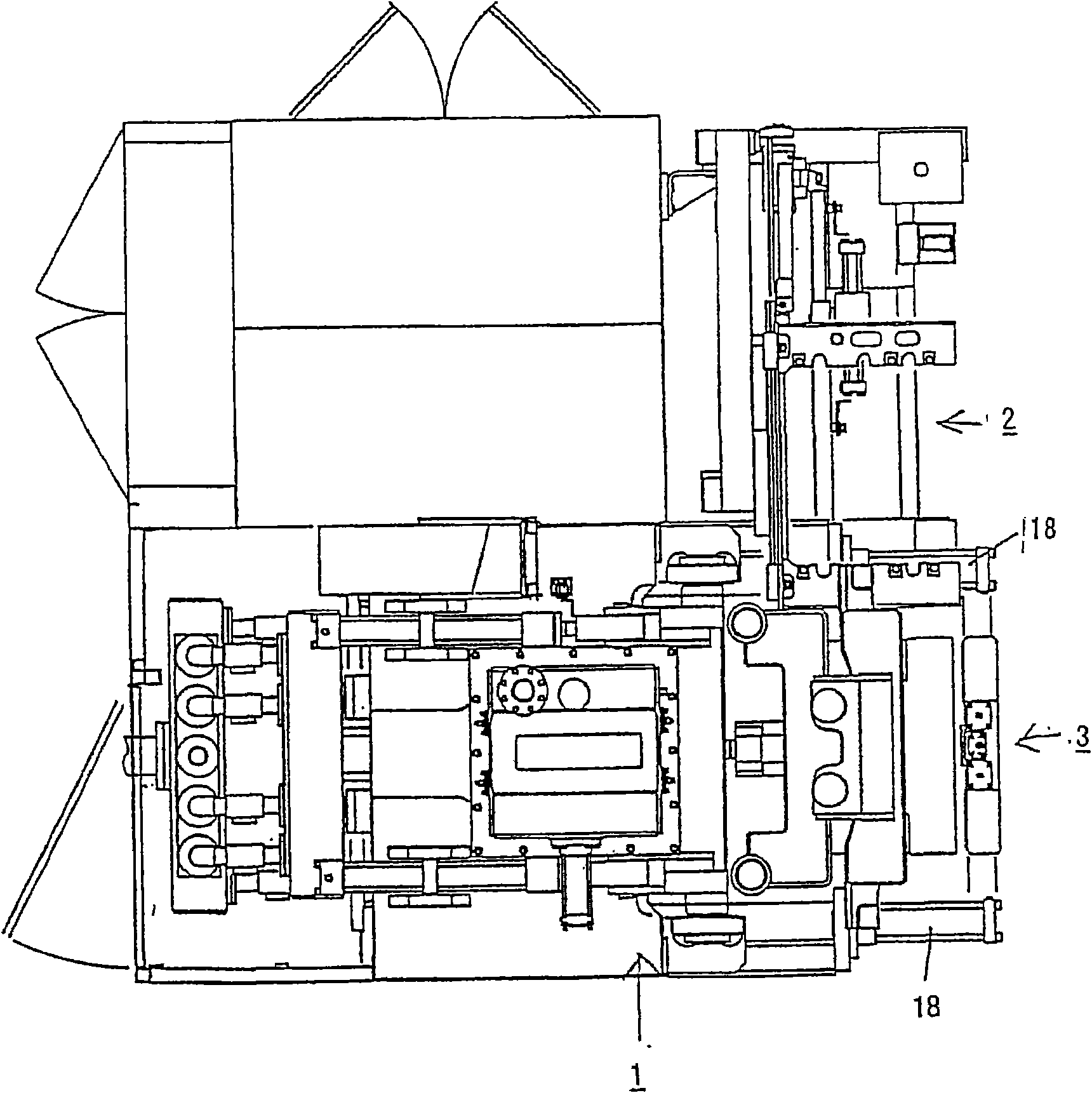

[0025] Figure 1 to Figure 4 One embodiment of the tankless molding device of the present invention is described. This boxless molding device generally includes a main body unit 1 positioned on a mechanical frame 20 of the device, and a double-sided template 11 ( figure 2 ) into and out of the transmission device 2 ( image 3 ), and a mold ejection device 3 for ejecting the final upper and lower molds molded in the main body unit 1 from the upper and lower flasks 12 and 13. Both sides of the double-sided template 11 are provided with patterns.

[0026] 1. The main unit of the molding device

[0027] On the styling device of the present invention, its main unit 1 will be described first. optimally, as figure 2 As shown, the main body unit 1 includes an upper sand box (a first sand box) 12 and a lower sand box (a second sand box) 13, the double-sided template 11 can be clamped therebetween, one can be inserted into the upper sand box and An upper extruding member 14 oppo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com