Star-structure organic inorganic hybridization green light material and preparation and application thereof

A star-shaped structure, luminescent material technology, applied in luminescent materials, silicon organic compounds, chemical instruments and methods, etc., can solve the problems of uneven dispersion, separation and purification not reaching the level of small molecules, uneven luminescence, etc. The process is simple, the source of raw materials is convenient, and the reaction speed is fast.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] Sodium azide POSS (14.58g 10mmol), compound 1 (see reaction formula 1) (45.14g 80mmol) and CuI (0.19glmmol) were added in the there-necked flask, under N 2 DMF10ml was added under atmosphere, and stirred at room temperature for 12 hours. After the initial product was filtered, it was successively washed with CHCl 3 , MeOH, H 2 O, THF, Et 2 O washed and dried under vacuum at 40°C for 12 hours. The molecular formula of the product is: (C 30 SiN 5 OBF 10 h 19 ) 8 Si 8 o 12 , Yield 95%, Luminescence peak wavelength: 661nm.

[0058] Chemical reaction formula 1:

[0059]

Embodiment 2

[0061] Sodium azide POSS and 2-(4-alkynylstyryl)-4-dinitrilemethylene-6-methylpyran hybrid materials

[0062] Sodium azide POSS (14.58g 10mmol), compound 1 (see reaction formula 2) (39.50g 70mmol) and CuI (0.19g1mmol) were added in the there-necked flask, under N 2 10 ml of DMF was added under atmosphere, and after stirring at room temperature for 12 hours, n-hexyne (0.82 g 10 mmol) was added. After the initial product was filtered, it was successively washed with CHCl 3 , MeOH, H 2 O, THF, Et 2 O washed and dried under vacuum at 40°C for 12 hours. The molecular formula of the product is: (C 30 SiN 5 OBF 10 h 19 ) 7 (C 9 SiN 3 Oh 18 ) Si 8 o 12 , Yield 92%, luminescence peak wavelength: 661nm.

[0063] Chemical reaction formula 2:

[0064]

Embodiment 3

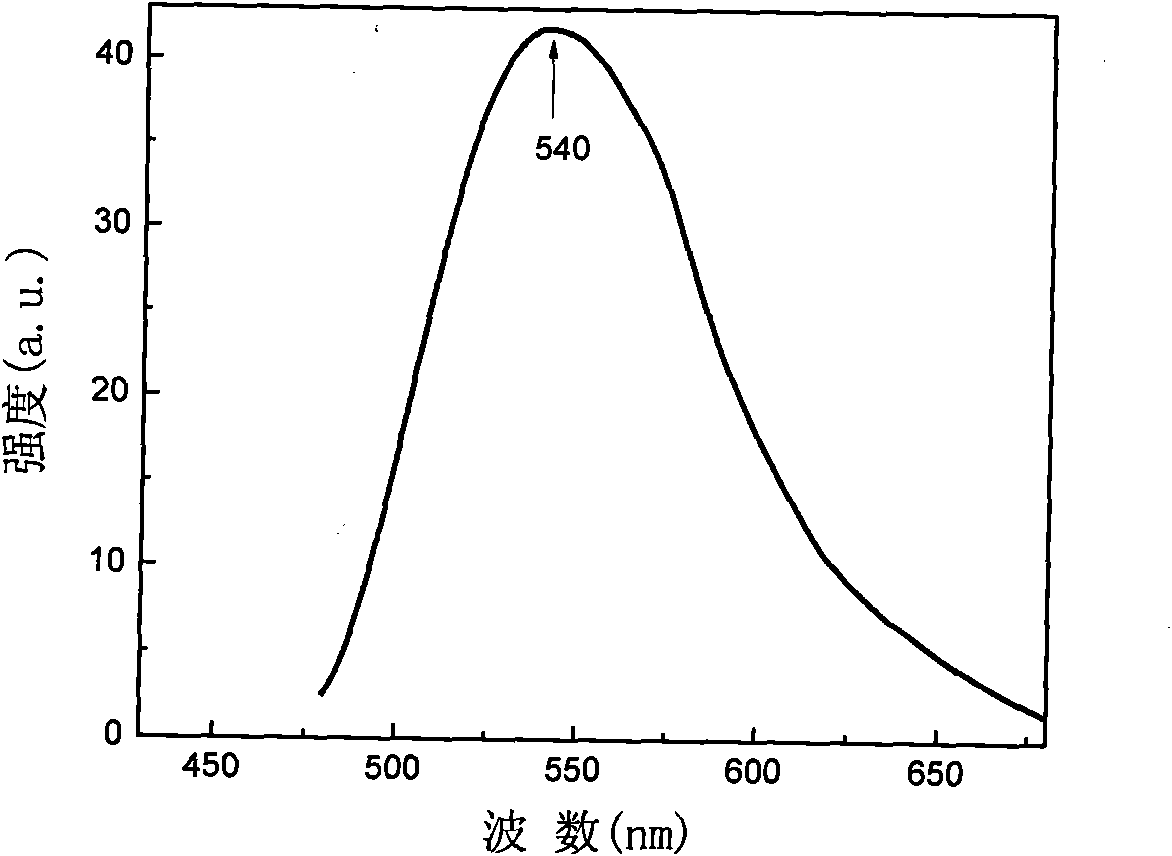

[0066] Octavinyl POSS (6.33g 10mmol) and compound 1 (see Reaction Formula 3) (45.78g 80mmol) were dissolved in 50ml DMF, and irradiated by ultraviolet light for 4h. After the initial product was filtered, it was successively washed with CHCl 3 , MeOH, H 2 O, THF, Et 2 O washed and dried under vacuum at 40°C for 12 hours. The molecular formula of the product is: (C 25 SN 2 BF 10 h 10 ) 8 Si 8 o 12 , Yield 99%, Luminescence peak wavelength: 540nm.

[0067] Chemical reaction formula 3:

[0068]

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap