Flexible expansion link mechanism

A telescopic rod and flexible technology, applied in the field of flexible telescopic rod mechanism, can solve problems such as affecting the quality and accuracy of OLED, substrate crushing or scratching, etc., to avoid hard collision, prolong opening or closing time, and reduce acceleration. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to describe the technical content and structural features of the flexible telescopic rod mechanism of the present invention in detail, further descriptions will be made below in conjunction with the embodiments and accompanying drawings.

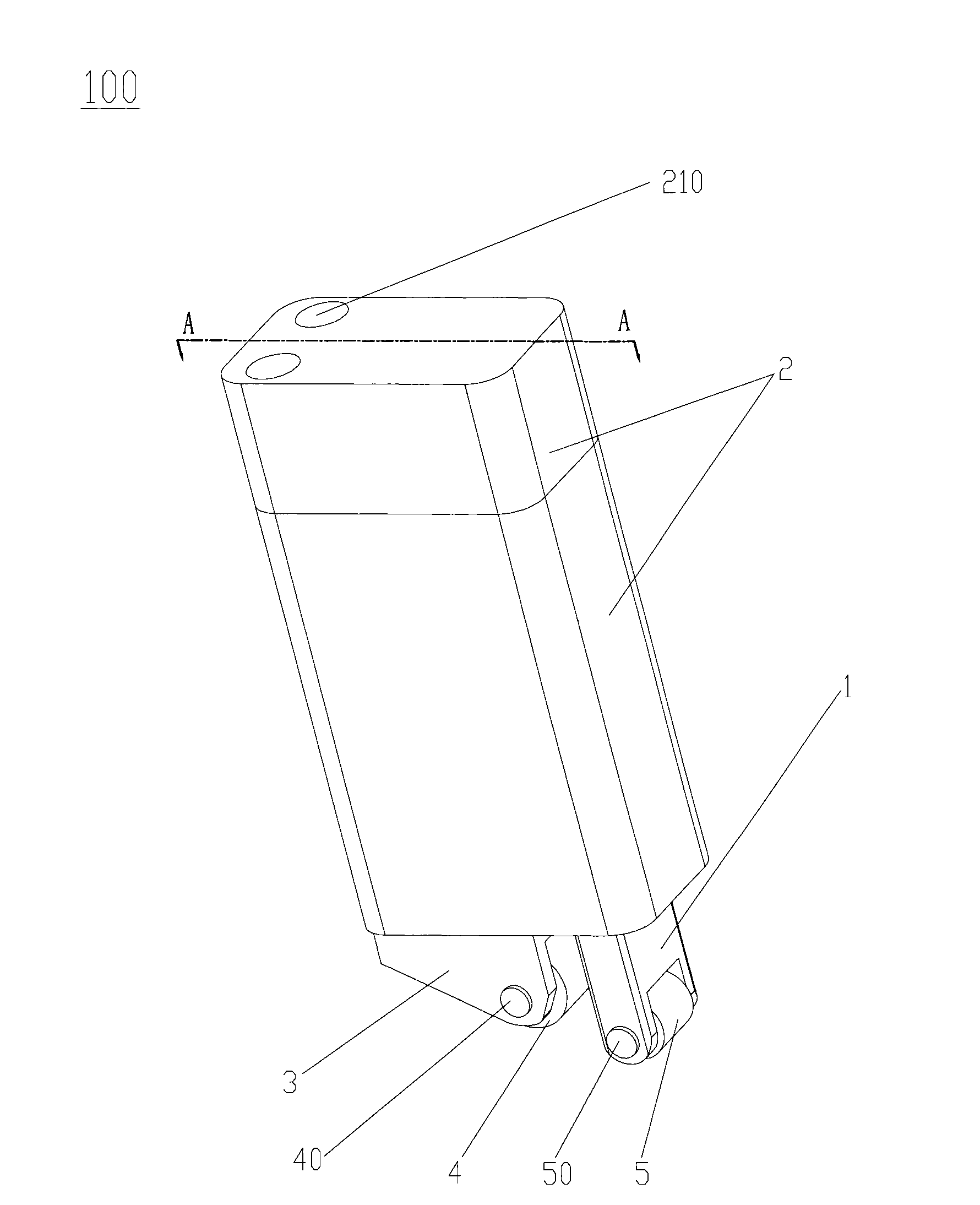

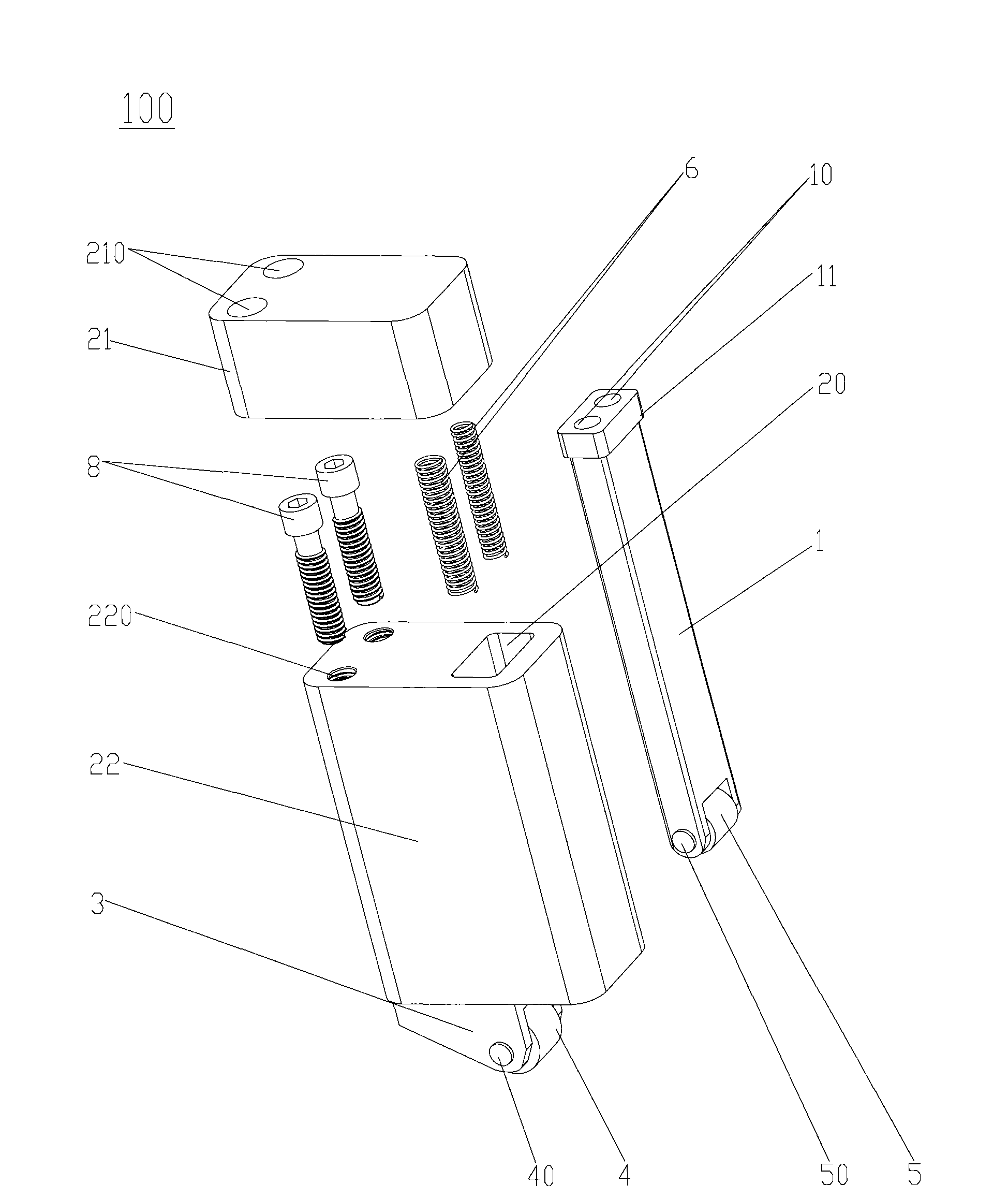

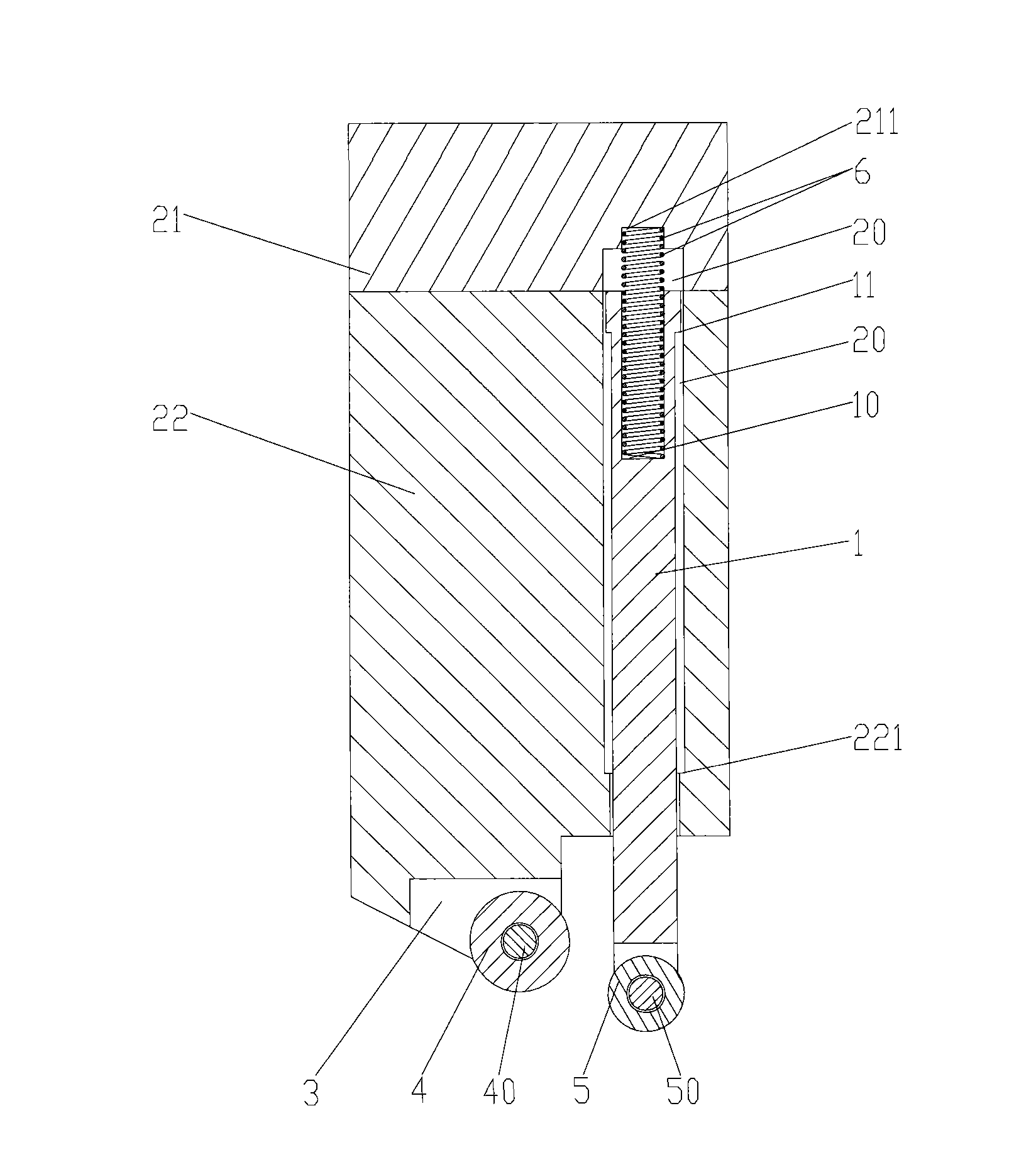

[0021] Such as figure 1 , figure 2 with Figure 4 As shown, the flexible telescopic rod mechanism 100 of the present invention is connected with the driving device (not shown in the figure) when working. The flexible telescopic rod mechanism 100 includes a rod frame 2 and a slave pressure rod 1. device connection, the lower end of the rod frame 2 has a main pressure rod 3 protruding outwards, and the rod frame 2 is provided with a sliding channel 20 for the sliding of the secondary pressure rod 1, and the secondary pressure rod 1 is clamped on the One end of the sliding channel 20 is in elastic contact with the rod frame 2, and the other end of the secondary pressing rod 1 extends out of the sliding channel 20 along the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com