Container underframe

A container and underframe technology, which is applied in the field of container underframe structure, can solve the problems of inconsistent external dimensions and inability to carry out intermodal transport of container ships, and achieve the effects of reducing dead weight, improving loading efficiency, and increasing internal height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

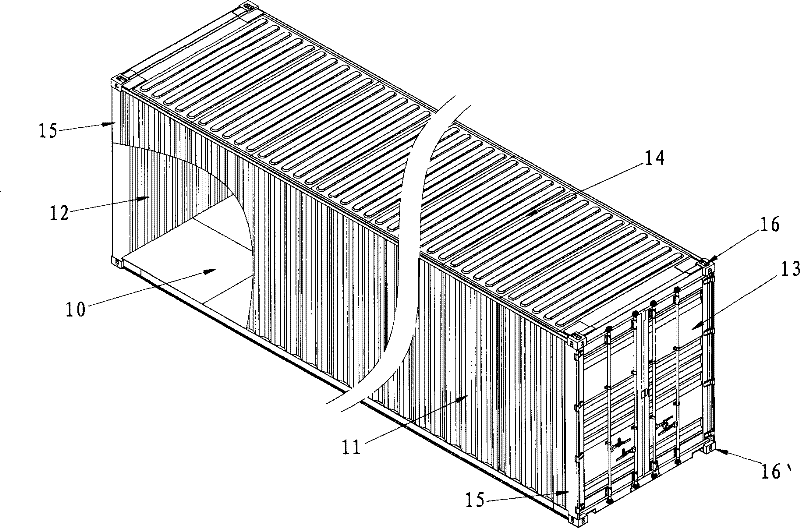

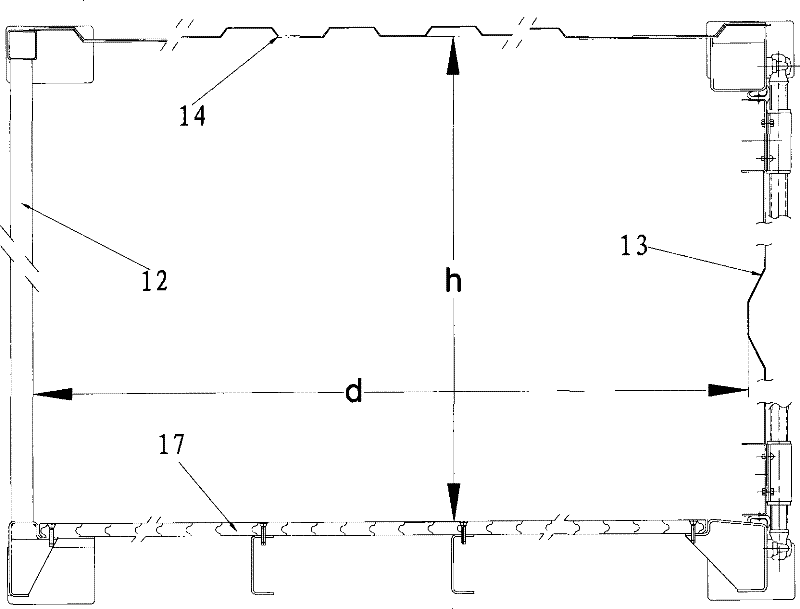

Embodiment 1

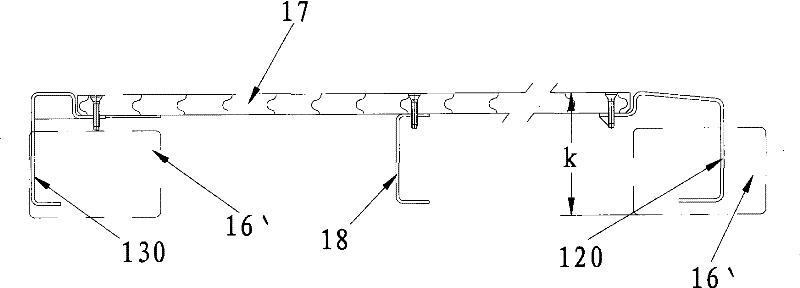

[0034] Such as Figure 4 , 5 The illustrated container underframe 3 includes bottom side beams 300 on both sides of the bottom frame, door sills 301 and front end lower beams 302 at both ends of the underframe, a plurality of parallel and arranged side by side between the door sill 301 and the front end lower beam 302 The bottom cross beam 303 is welded with bottom corner pieces 361 at both ends of the door sill 301 and both ends of the front lower beam 302; the aforementioned bottom side beam 300, bottom cross beam 303, door sill 301, and front end lower beam 302 are welded and connected to form a frame body, The wooden floor 37 is laid on the frame body, and its middle part is supported on the top surface of the bottom beam 303. The inner end of the door sill 301 is provided with a sill bending section 3011 that is downward and whose upper surface is flush with the top surface of the bottom beam 303 for carrying the wooden floor 37. Correspondingly, in order to ensure the flat...

Embodiment 2

[0040] In order to increase the inner height of the container more effectively, reduce the height of the bottom frame of the container, such as Figure 8 , 9 As shown, a recess 3611 is provided on the matching part of the bottom corner piece 361 for overlapping with the wooden floor 37, and the end corner of the wooden floor 37 can be placed in the recess 3611. The depth of the recess 3611 is the same as that of the wooden floor 37. The thickness is the same, so that the upper surface of the wooden floor 37 is flush with the upper surface of the bottom corner piece 361. Here, the purpose of opening the recess 3611 on the bottom corner piece is to maintain the structural integrity of the wooden floor 37. From the perspective of achieving the purpose of supporting the bottom corner piece 361 on the wooden floor 37, such as Picture 10 In the manner shown, a support platform 3612 for supporting the wooden floor is provided on the periphery of the inner side of the bottom corner pie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com