Spacial multi-angle truss structure

A truss structure and multi-angle technology, applied in the field of truss structures, can solve the problem that the truss connection nodes cannot adapt to the change of the connection angle of the truss rods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

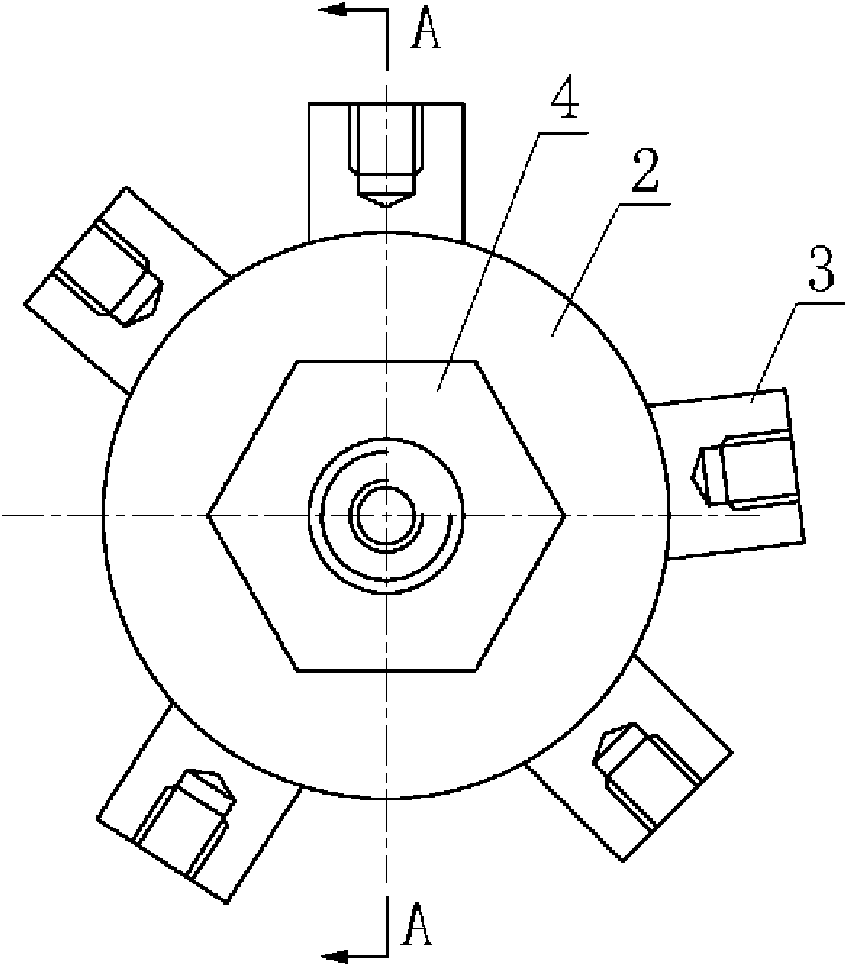

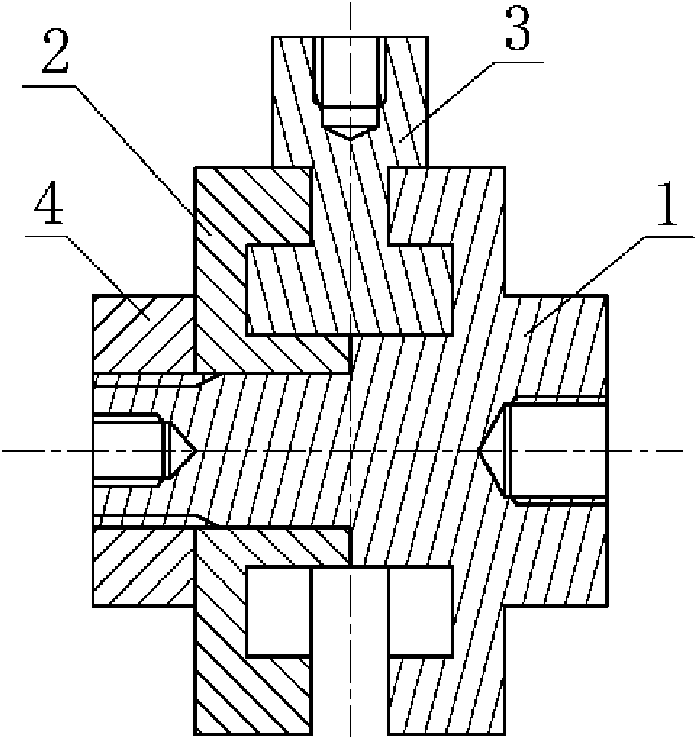

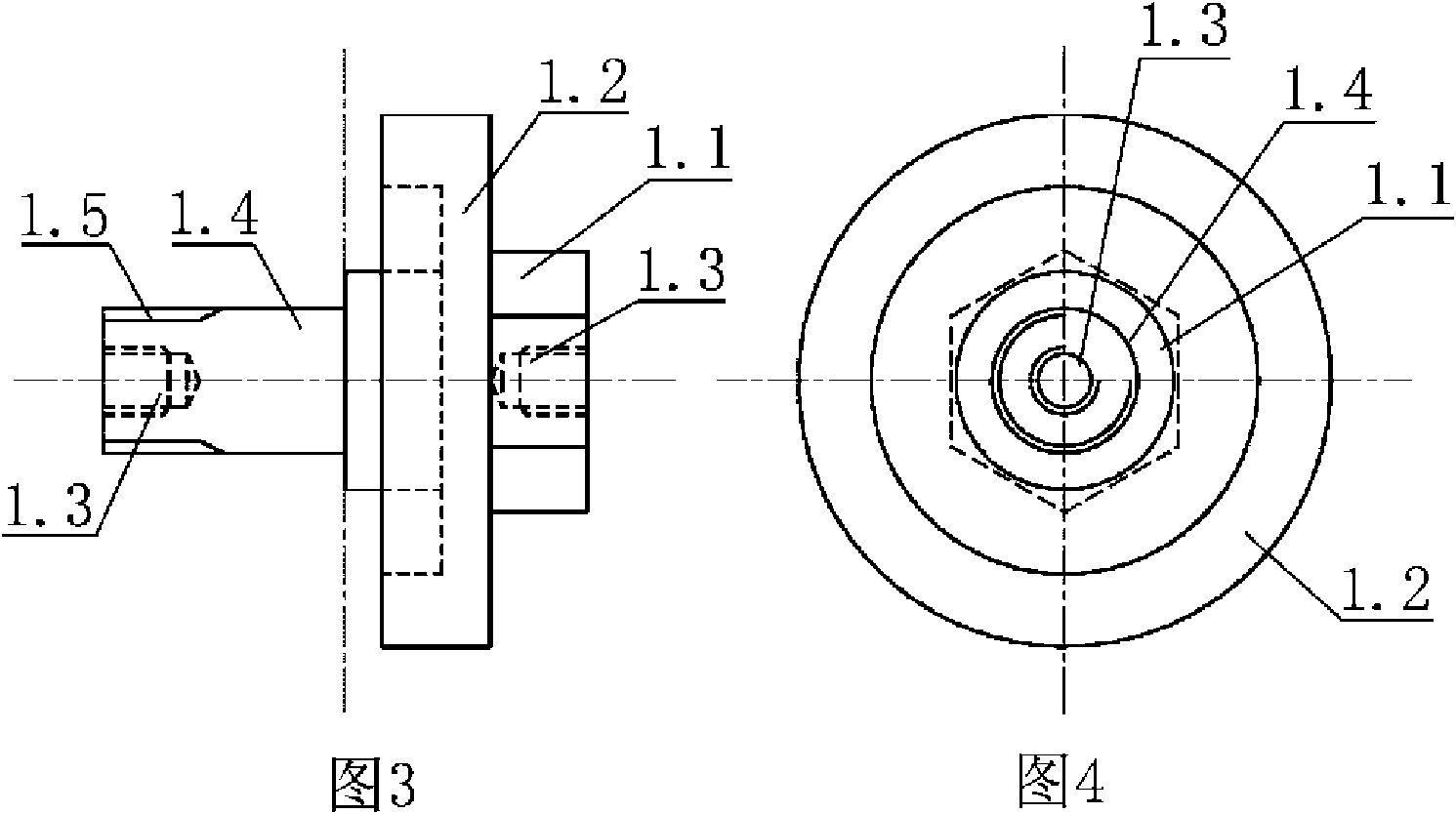

[0035] Referring to the embodiment shown in Figure 1417, this space multi-angle truss structure is composed of truss rods 5, space bolt ball nodes 6 and multi-angle variable nodes 7. see Figure 1-5 , the multi-angle variable node is composed of bushing 1, sliding bushing 2, slider 3 and nut 4. The center of bushing 1 is in the shape of a stepped shaft, and the two ends of the stepped shaft are respectively provided with concentric joints that can be connected with truss rods. Screw hole 1.3, the high-order shaft 1.1 of the stepped shaft extends a disc-shaped bushing chute 1.2, and the end of the low-order shaft 1.4 of the stepped shaft has an external thread 1.5. The center of the shaft sleeve 1 is in the shape of a three-stage or two-stage stepped shaft 1.1.

[0036] see figure 1 , figure 2 , Figure 68, the sliding sleeve 2 is set on the lower shaft 1.4 of the stepped shaft and fixed by the nut 4, the inner diameter of the sliding sleeve 2.1 is adapted to the outer diame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com