Pontoon metering system of wharf materials

A measurement system and material technology, applied in the field of large-scale material measurement system, can solve the problems of large errors, many human factors, and it is difficult to contain fraud, and achieve the effect of accurate and reliable measurement, small human factors, and easy measurement management.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the accompanying drawings.

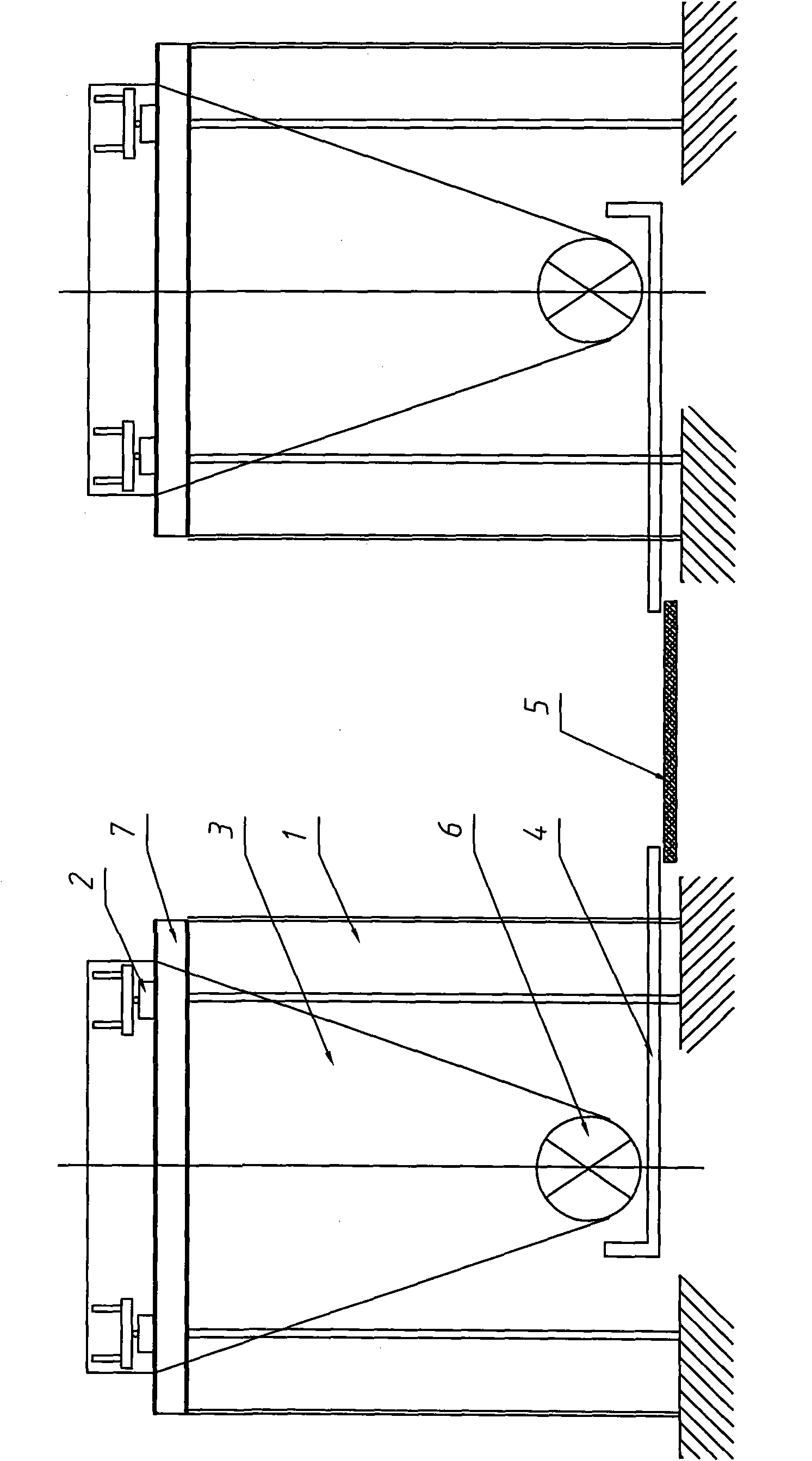

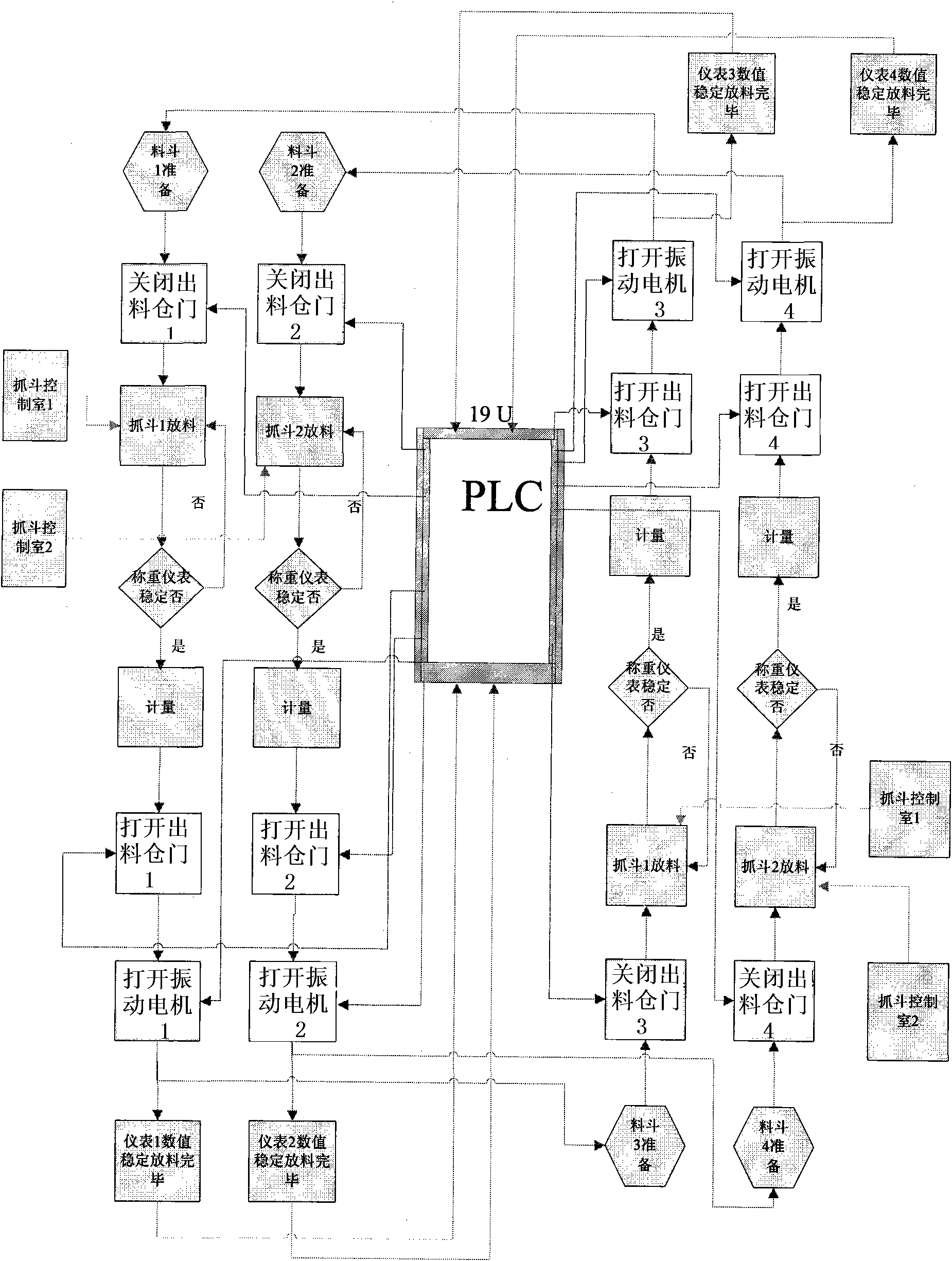

[0013] Such as figure 1 as shown ( figure 1 Only the mechanical parts of the system have been shown), the wharf material barge metering system of the present invention includes a control circuit, a support column 1, a load cell 2, a weighing instrument, a hopper 3, a material transfer shuttle plate 4 and a material conveying belt 5 , the load cell 2 is arranged on the top of the supporting column 1, the load cell 2 is electrically connected with the weighing instrument, and the hopper 3 is carried on the load cell 2 and suspended in the air. The material transfer shuttle plate 4 is used to transfer the material released by the hopper to the material conveying belt 5, and then the material is conveyed to the warehouse built on the side of the wharf by the material conveying belt. One end of the feeding shuttle plate 4 is located below the hopper discharge bin door 6, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com