Method for manufacturing alignment film

A production method and technology of alignment film, which can be applied to instruments, coatings, pre-treated surfaces, etc., and can solve problems such as stripe defects of liquid crystal panels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

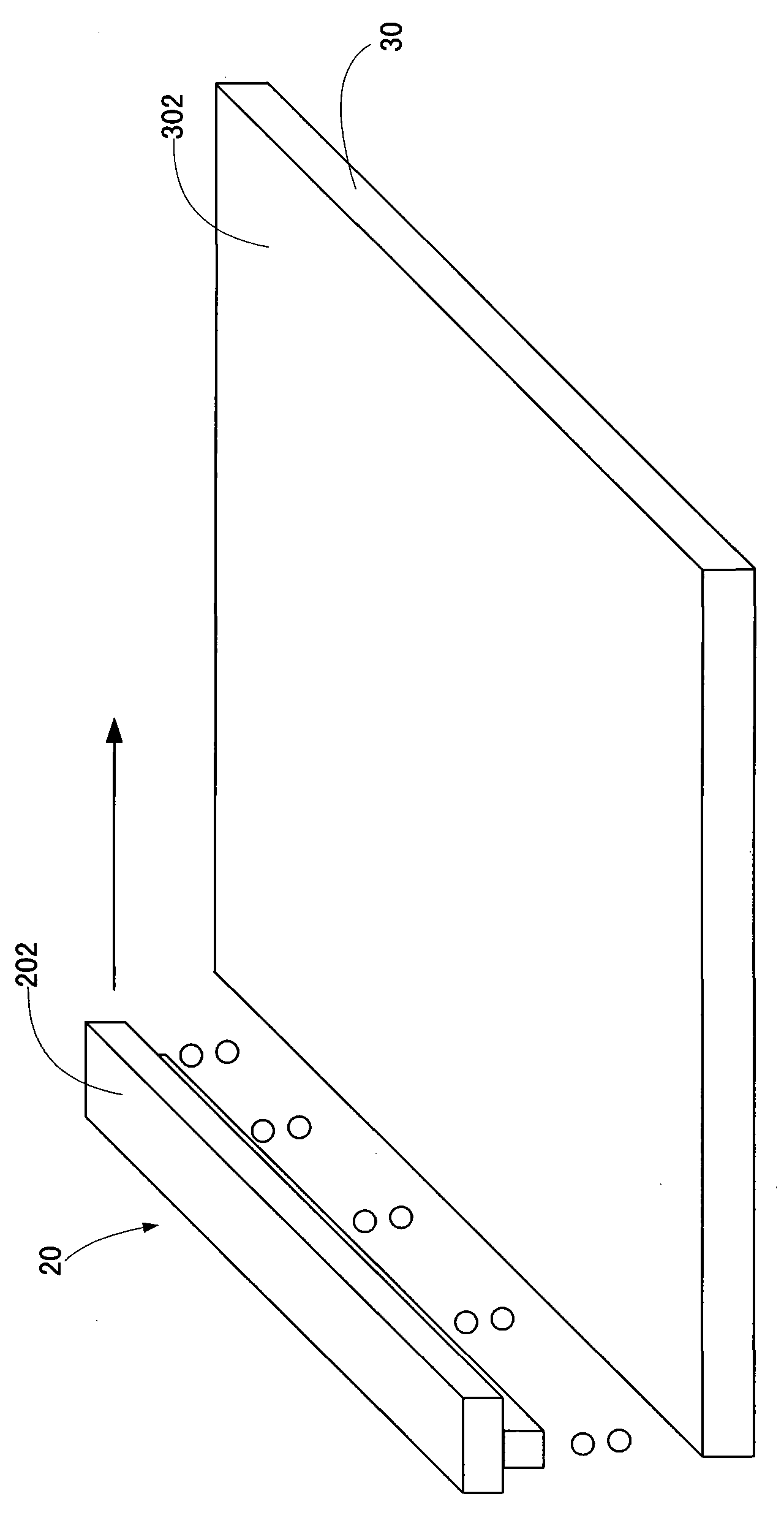

[0014] The embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

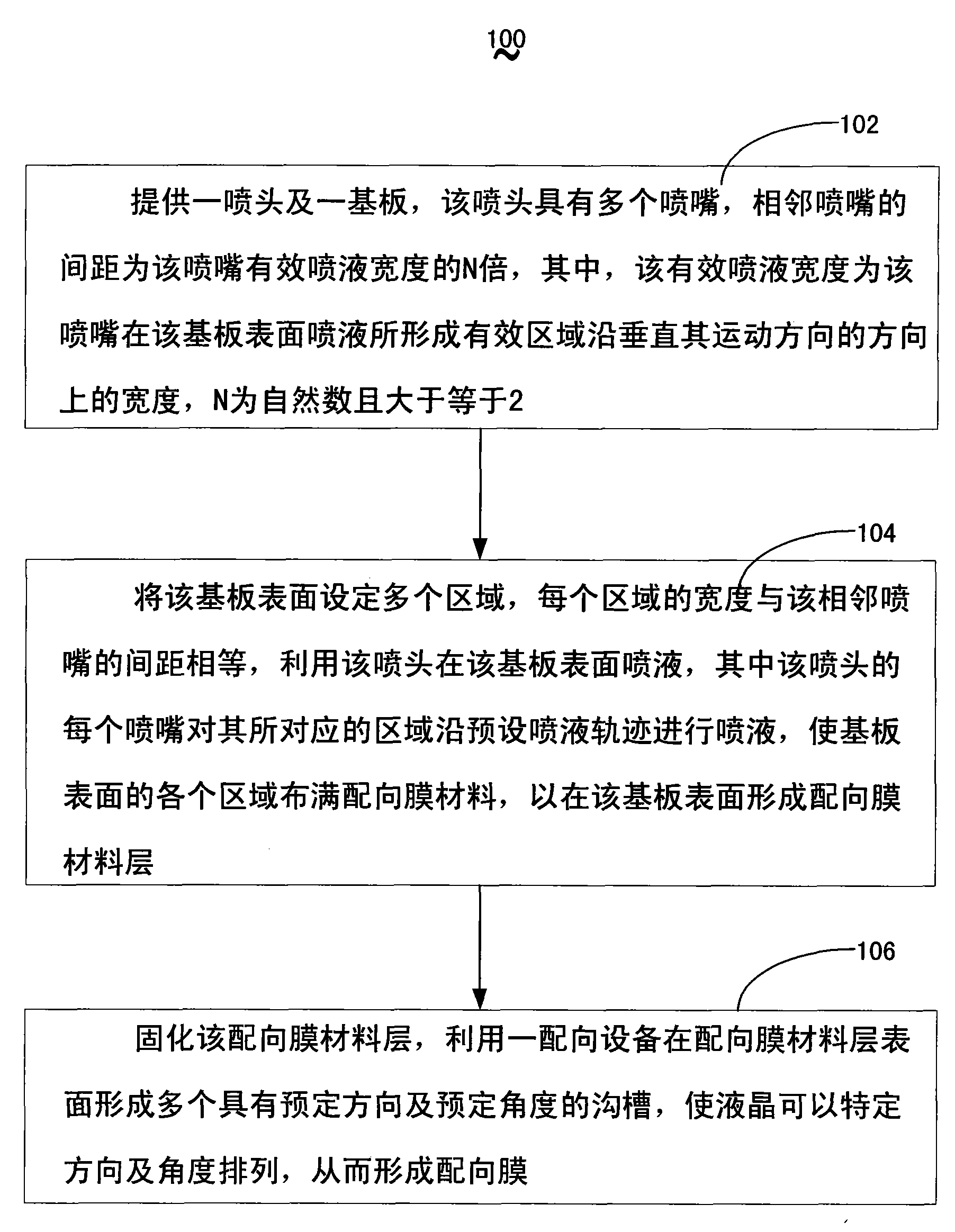

[0015] see figure 1 , the embodiment of the present invention provides a method 100 for manufacturing an alignment film, which includes the following steps:

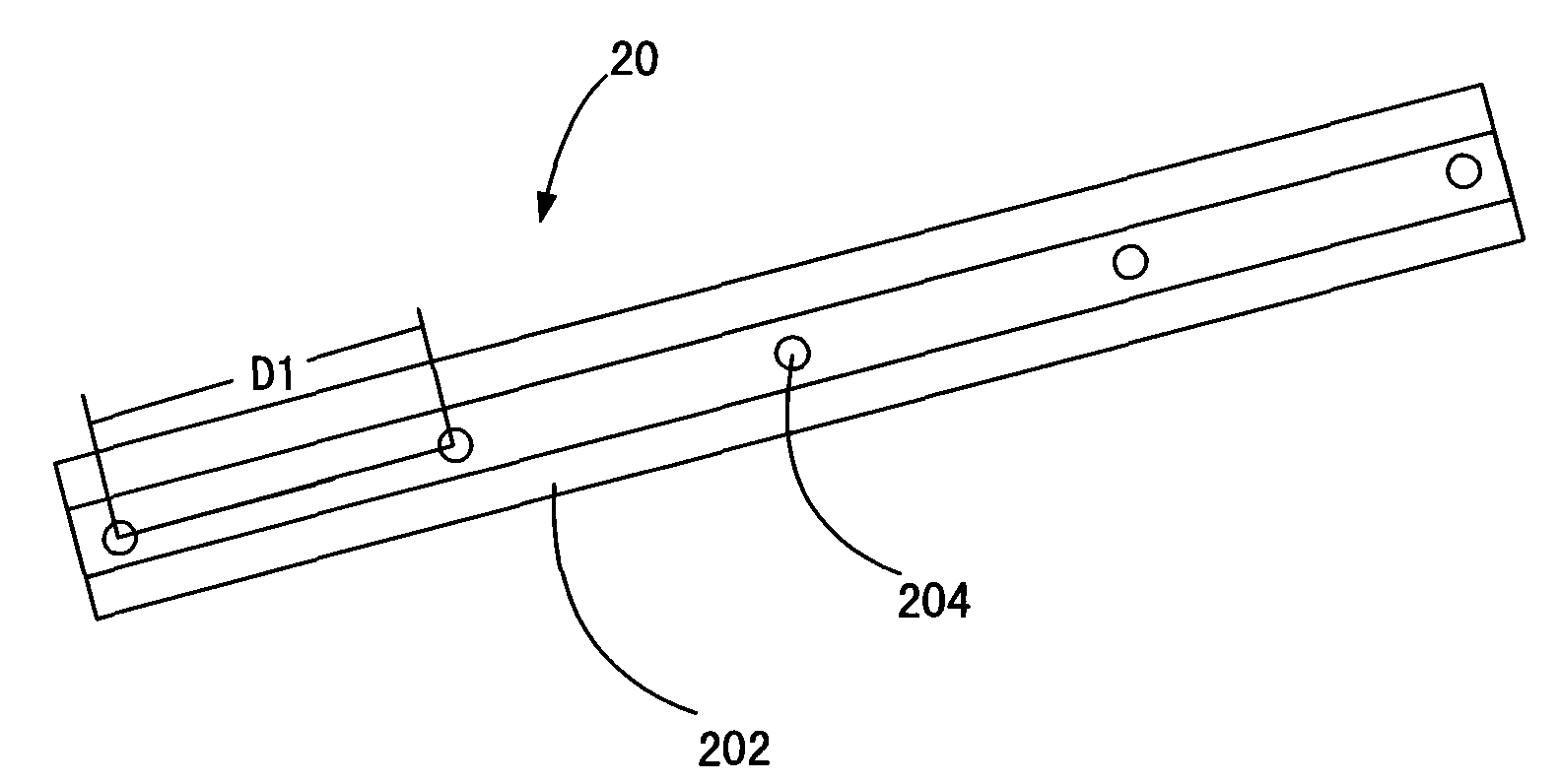

[0016] Step 102: Provide a spray head and a substrate, the spray head has a plurality of nozzles, and the distance between adjacent nozzles is N times the effective liquid spray width of the nozzle, wherein the effective liquid spray width is the width of the liquid sprayed by the nozzle on the surface of the substrate Form the width of the effective area along the direction perpendicular to its movement direction, N is a natural number and greater than or equal to 2;

[0017] Step 104: Setting multiple regions on the surface of the substrate, the width of each region is equal to the distance between the adjacent nozzles, using the nozzle to spray liquid on the surface of the substra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com