Method for assembling spherical hinge rubber elastic element and product thereof

A technology of elastic components and assembly methods, applied in the direction of pivot connection, etc., to achieve the effect of improving axial extrusion force, ensuring safety, and flexible adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

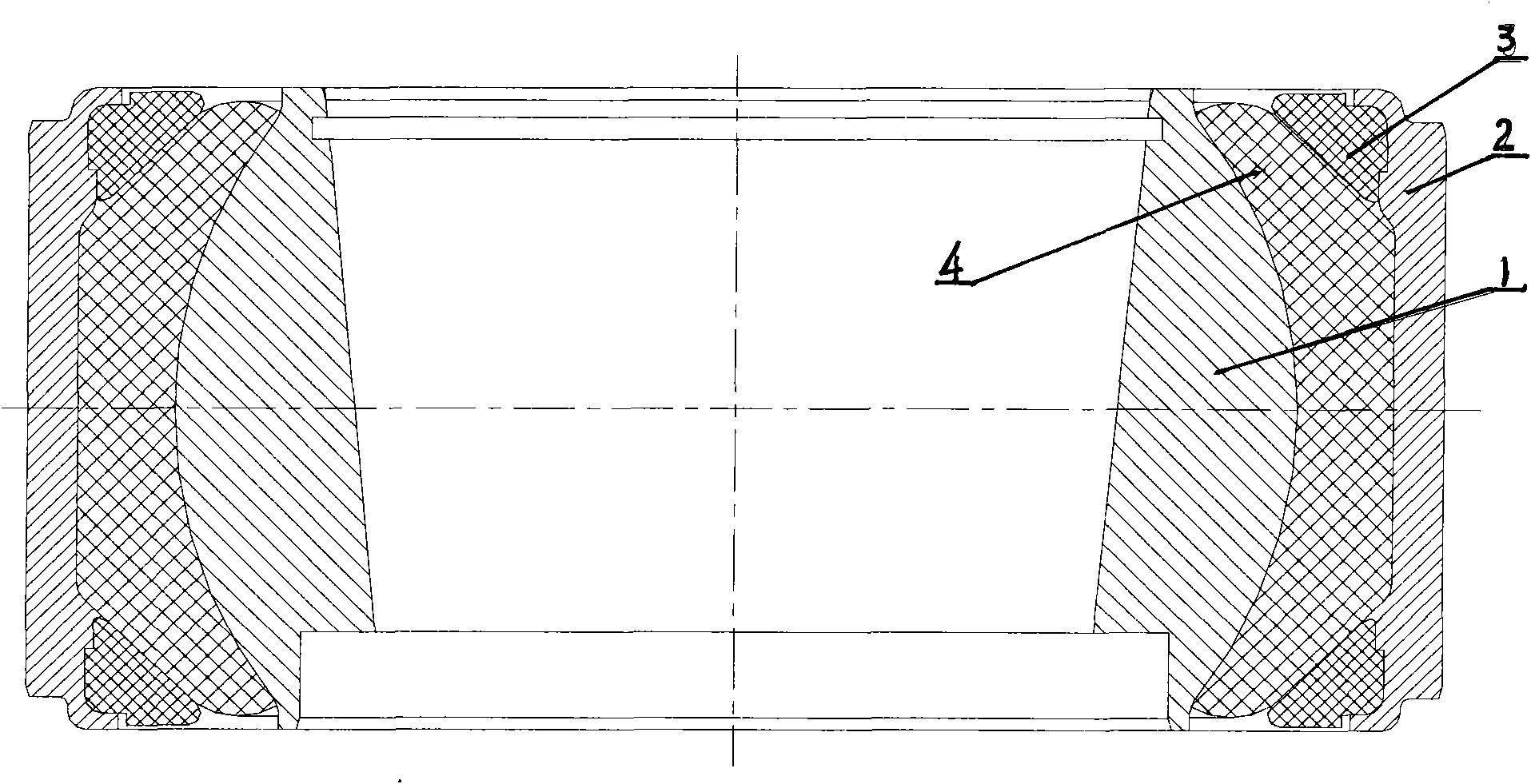

[0019] figure 1 A specific embodiment of the present invention is given, and it can be seen from the accompanying drawings that the present invention is a ball joint type rubber elastic element, including a metal inner sleeve (or mandrel) 1, a metal outer sleeve 2, and an elastic rubber body 4 , the metal stopper 3, the elastic rubber body 4 and the metal inner sleeve (or mandrel) 1 are vulcanized into an elastic body, and the elastic body is pressed into the metal outer sleeve 2; Edge; a metal stopper 3 is pressed on the outer edge of the elastic rubber body 4, and the metal stopper 3 is wrapped inwardly by the flanging of the metal jacket 2, so that the metal stopper 3 compresses the elastic rubber body to form a pre-compressive stress. There are two metal stoppers 3 , and one side of the elastic rubber body 4 in the axial direction.

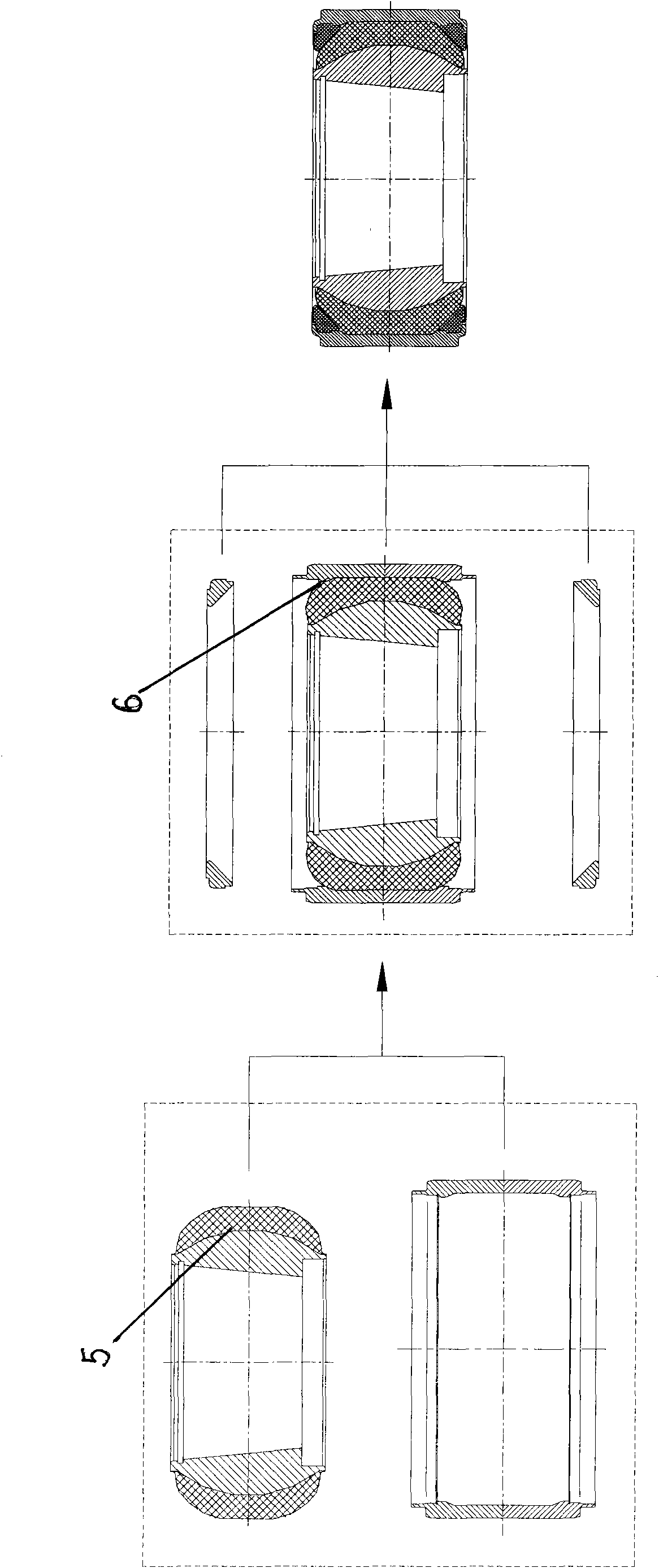

[0020] The production of spherical hinge rubber elastic elements is as follows: image 3 shown. The specific assembly steps are as follows...

Embodiment 2

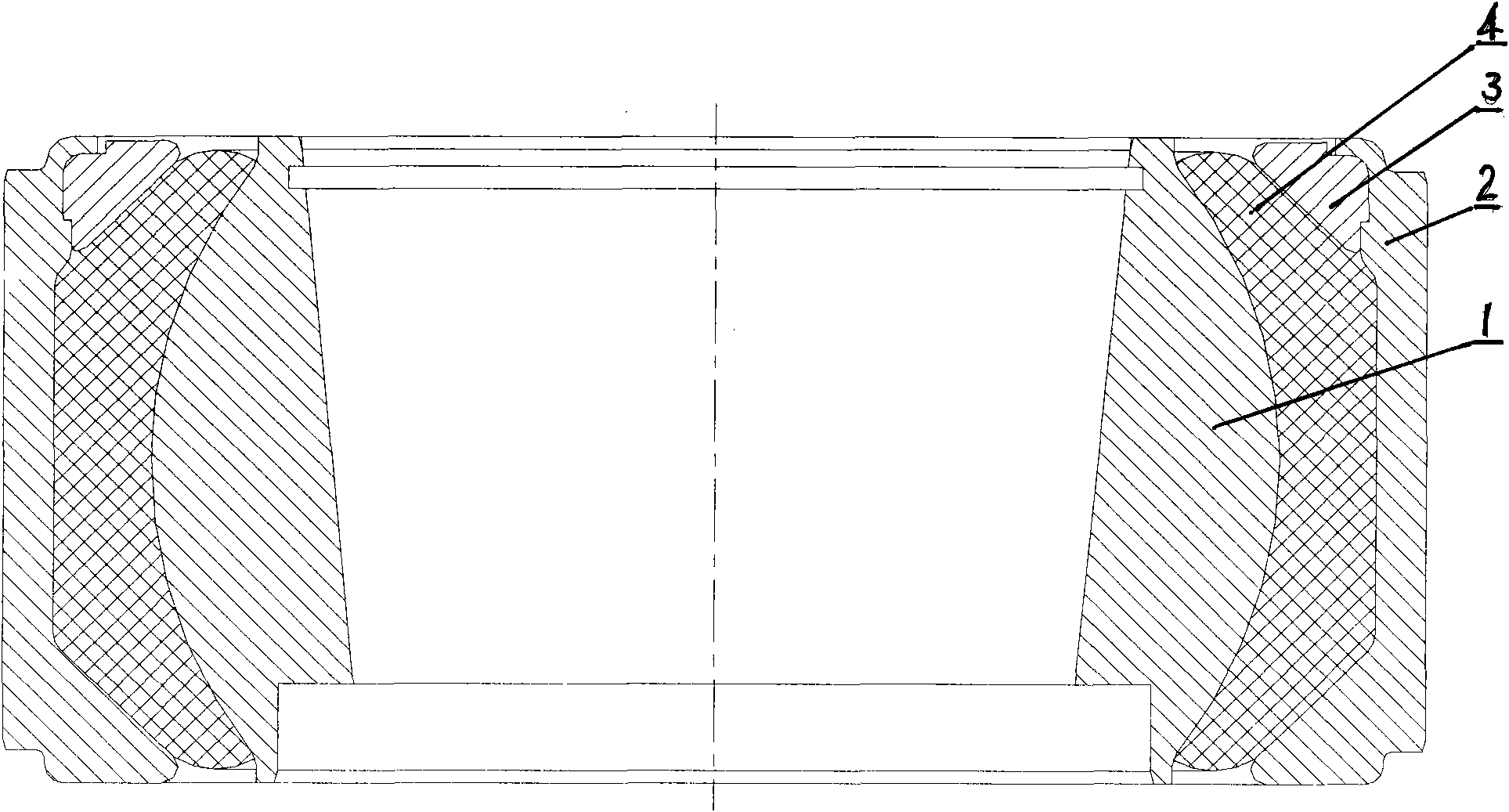

[0025] The structure of the second embodiment is similar to that of the first embodiment, except that the number of metal stoppers is changed from two to one, and only one is provided on either side of the elastic rubber body 4 in the axial direction. In this way, compared with the first embodiment, the axial precompression stress is adjusted, so that the axial stiffness is further reduced.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com