Template system capable of internally erecting and detaching mould

A formwork and integral technology, applied in the fields of formwork/formwork/work frame, on-site preparation of building components, construction, etc., can solve the safety risks in construction operations, the labor intensity of workers, and the long time for vertical formwork removal, etc. problem, to achieve the effect of simple structure, high work efficiency and stable moving speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

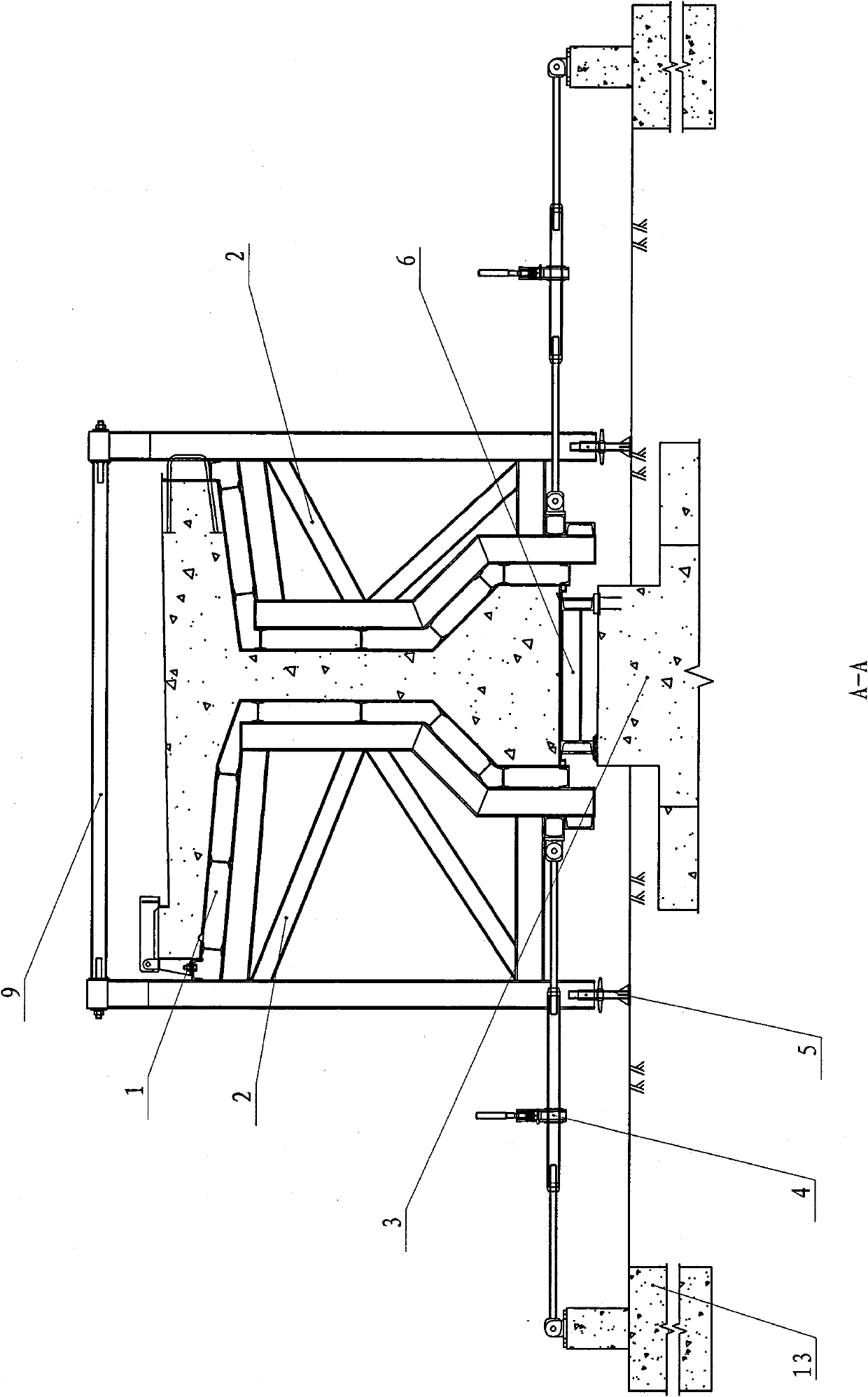

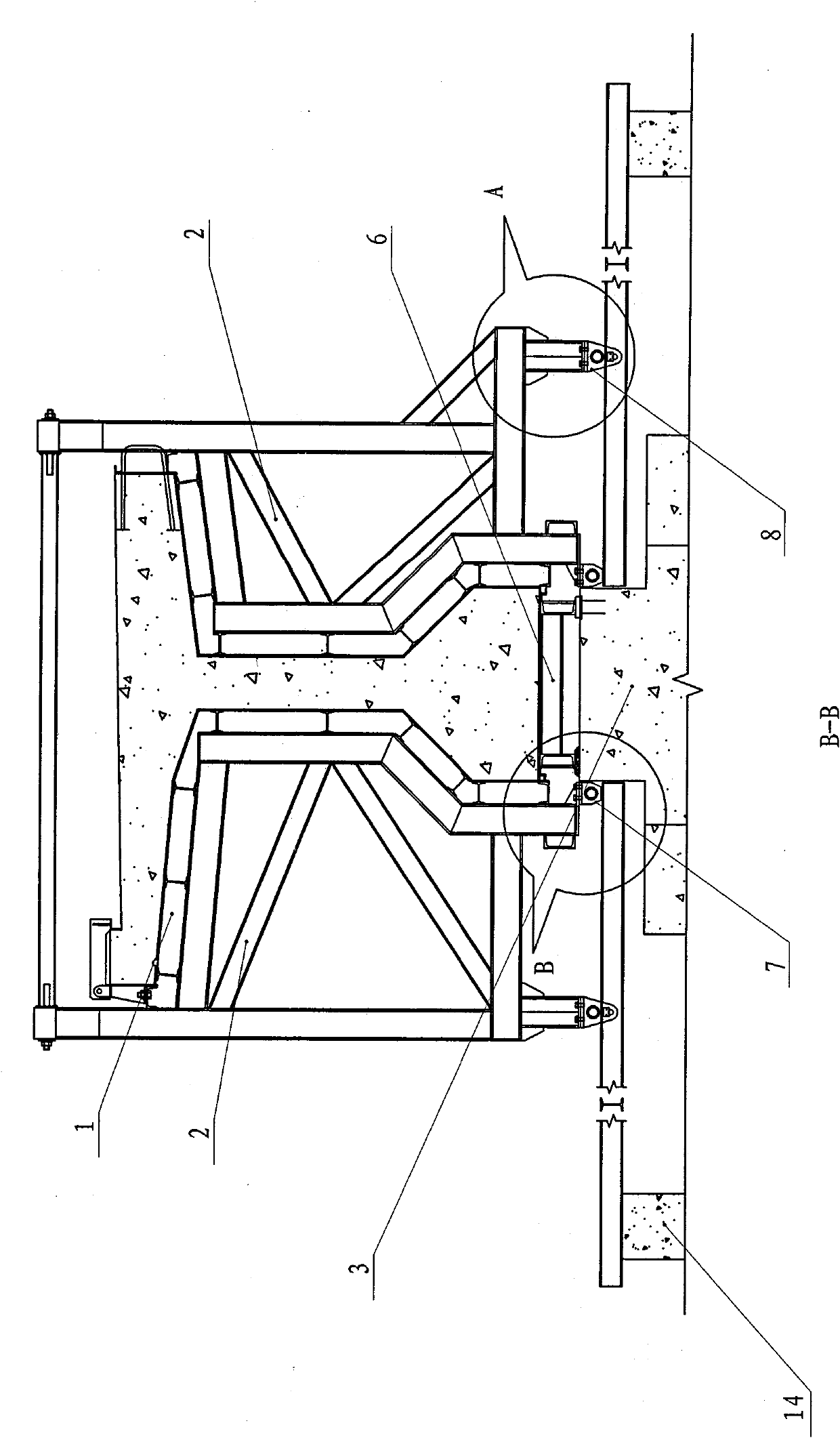

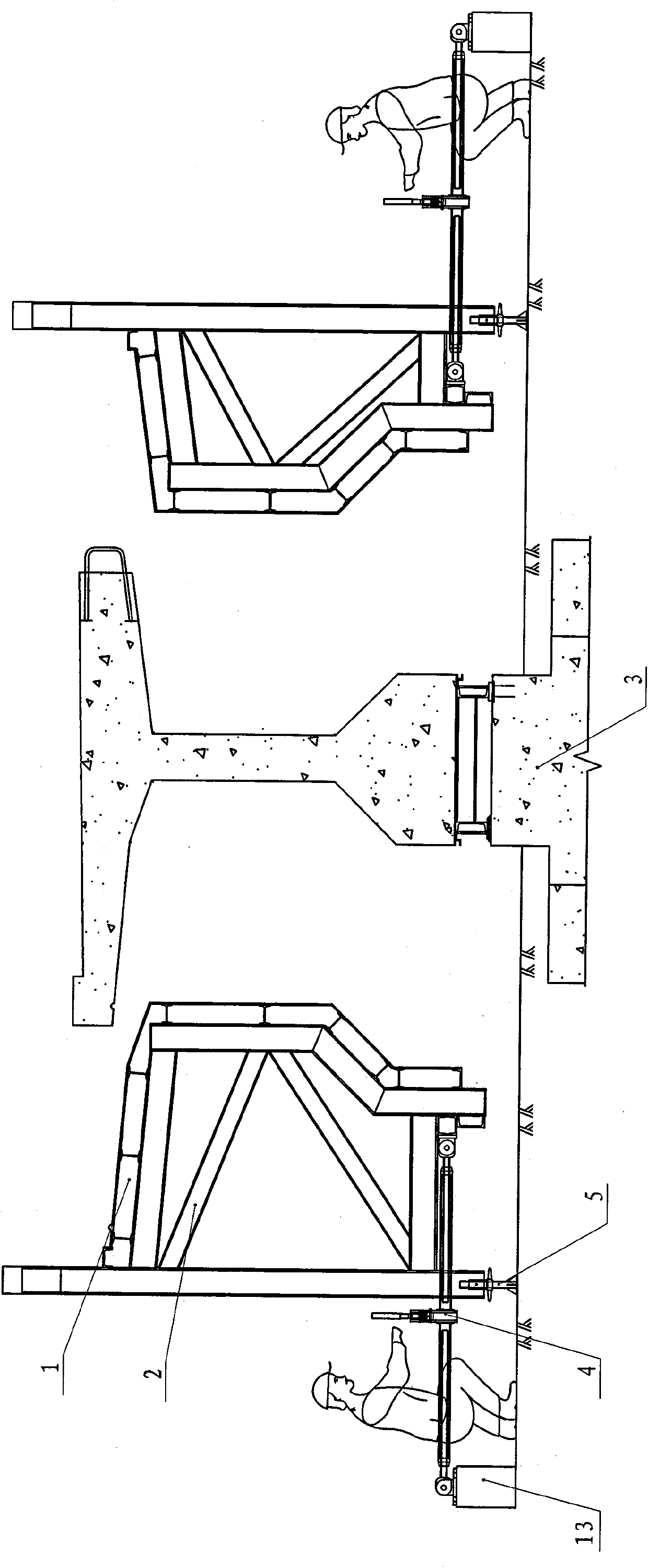

[0030] Embodiment: See accompanying drawings 1-8 of the description, in which 1-both sides formwork, 2-support, 3-bottom mold base, 4-support driving device, 5-adjustable vertical support seat, 6-bottom formwork, 7-Bracket inner caster assembly, 8-Bracket outer caster assembly, 9-Lateral tie rod, 13-Drive base, 14-Rail base; 8-1 is "π" shaped frame plate, 8-2 is clamp plate, 8-3 is a reverse buckle axle, 8-4 is a roller, and 8-5 is a reverse buckle wheel; 7-1 is a "π" shape frame plate, and 7-2 is a roller; 4-1 is a driving rod, and 4-2 is a Elastic dry, 4-3 is a sleeve, 4-4 is a bolt rod; 5-1 is a tubular long nut with a handle, and 5-2 is a screw with a flat seat.

[0031] The formwork system that can be erected and disassembled as a whole includes a base, a formwork and its bracket. The formwork includes two side formworks and a bottom formwork, the bottom formwork is fixed on the base, and the bottom formwork and the two side formworks are connected by bolts The upper par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com