Double powered variable transmission for electric automobile

A continuously variable transmission, electric vehicle technology, applied in transmissions, vehicle components, gear transmissions, etc., can solve the problem that it is difficult to meet the economical and vehicle cost requirements of electric vehicles, and is not suitable for high-torque climbing and muddy road driving. , hindering the speed of high-speed operation of automobiles, etc., to meet the requirements of economy and vehicle cost, easy to implement, and easy to assemble

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

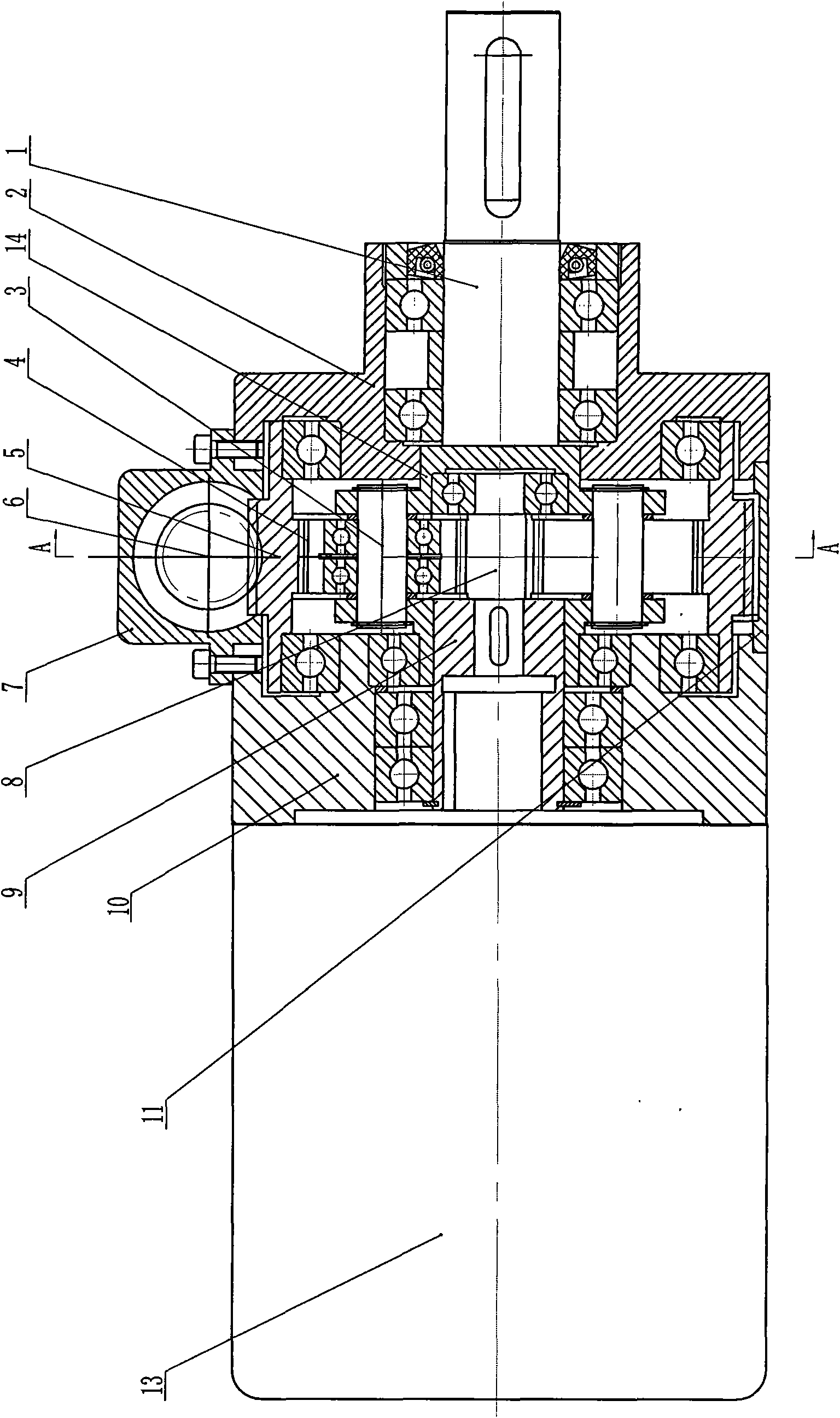

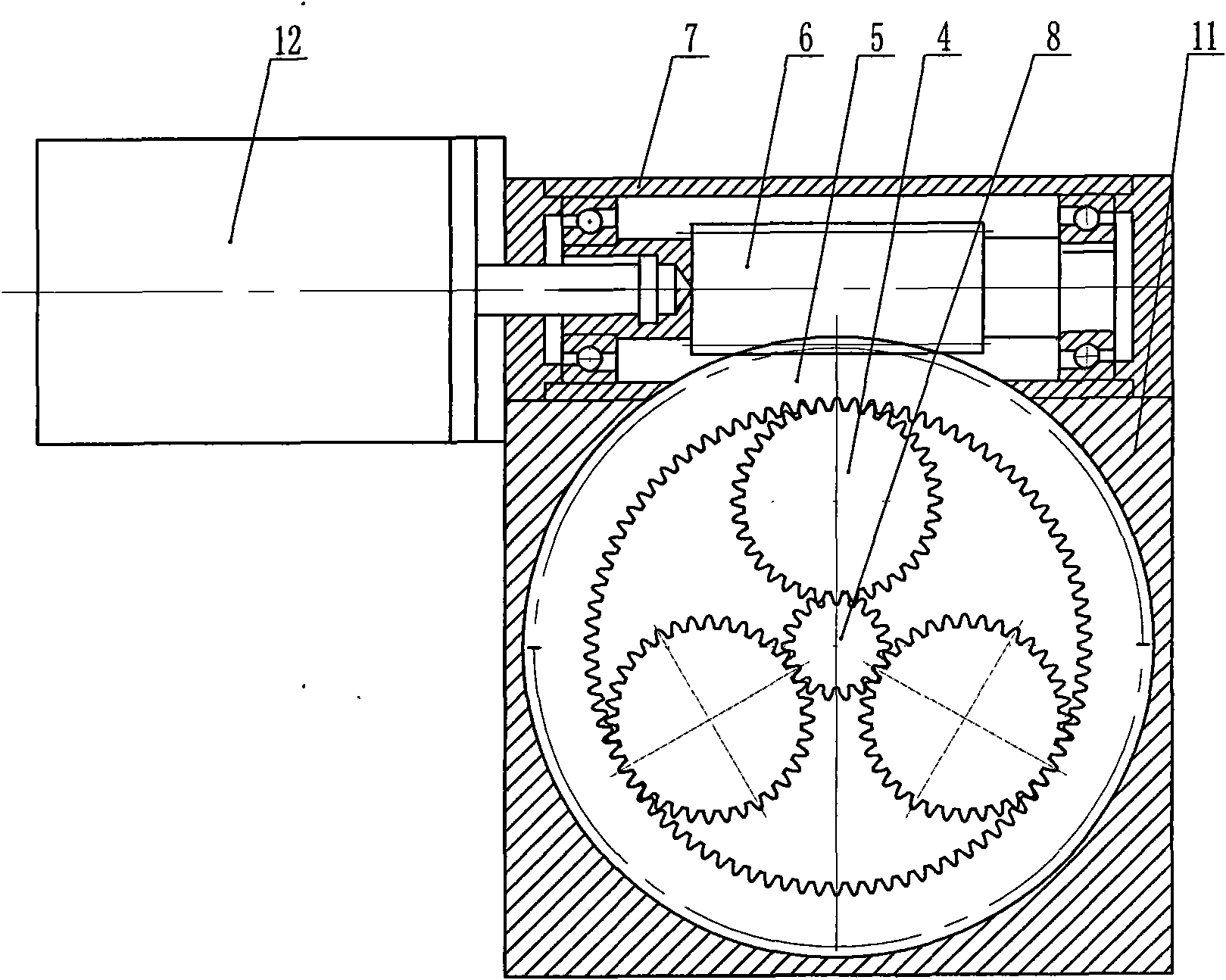

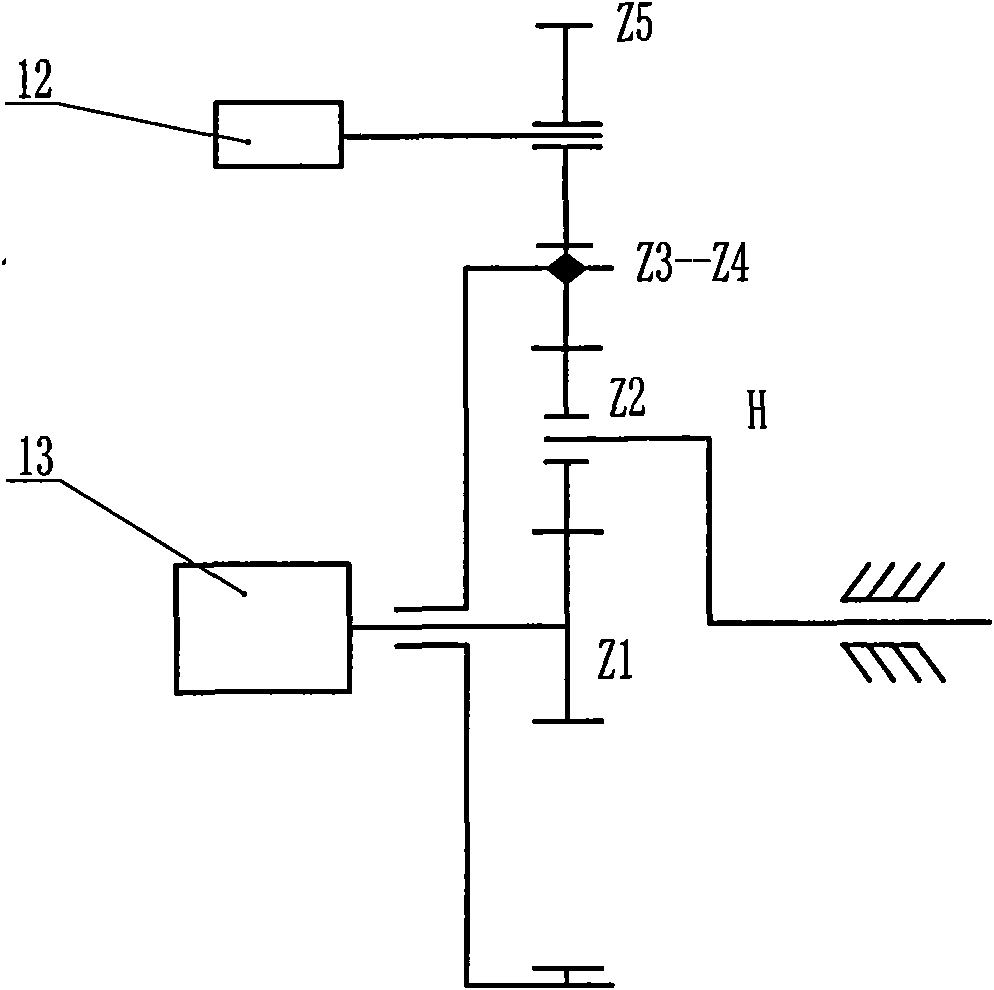

[0021] like figure 1 , figure 2 As shown, the present invention consists of an output shaft 1, an end cover 2, a planetary gear shaft 3, a planetary gear 4, a ring gear 5, a worm 6, a worm housing 7, a sun gear 8, an input shaft 9, a connecting body 10, and a middle housing 11. It is composed of adjusting motor 12, main power motor 13, planet carrier 14, several bearings, retaining rings and other accessories. The casing of the main power motor 13 is fixed on the left end of the connecting body 10 by screws, and the right end of the connecting body 10 is fixed with the end cover 2 through the middle casing 11, and the ring gear 5 and the planetary gear 4 are arranged in the middle casing 11 , planetary carrier 14 and sun gear 8, wherein planetary gear 4 is between ring gear 5 and sun gear 8, and number is 2-8, preferably 3 in the present embodiment, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com