Frock clamp

A technology of tooling fixtures and clamping blocks, which is applied in the field of tooling fixtures, can solve problems such as low efficiency, inconvenient work efficiency, and complicated operation of tooling fixtures, and achieve the effect of simple actions and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

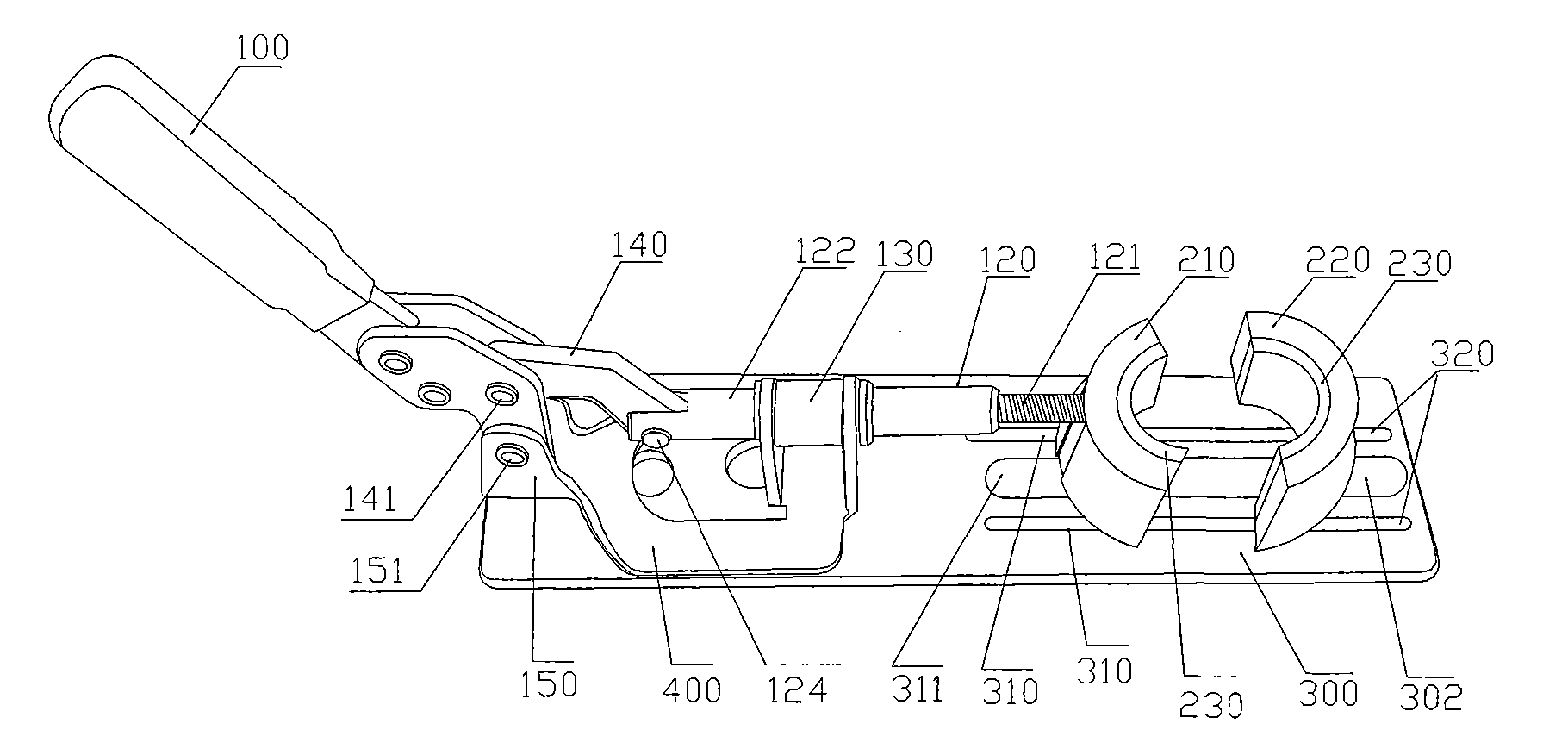

[0020] Figure 1 to Figure 4 A preferred embodiment of the present invention is shown.

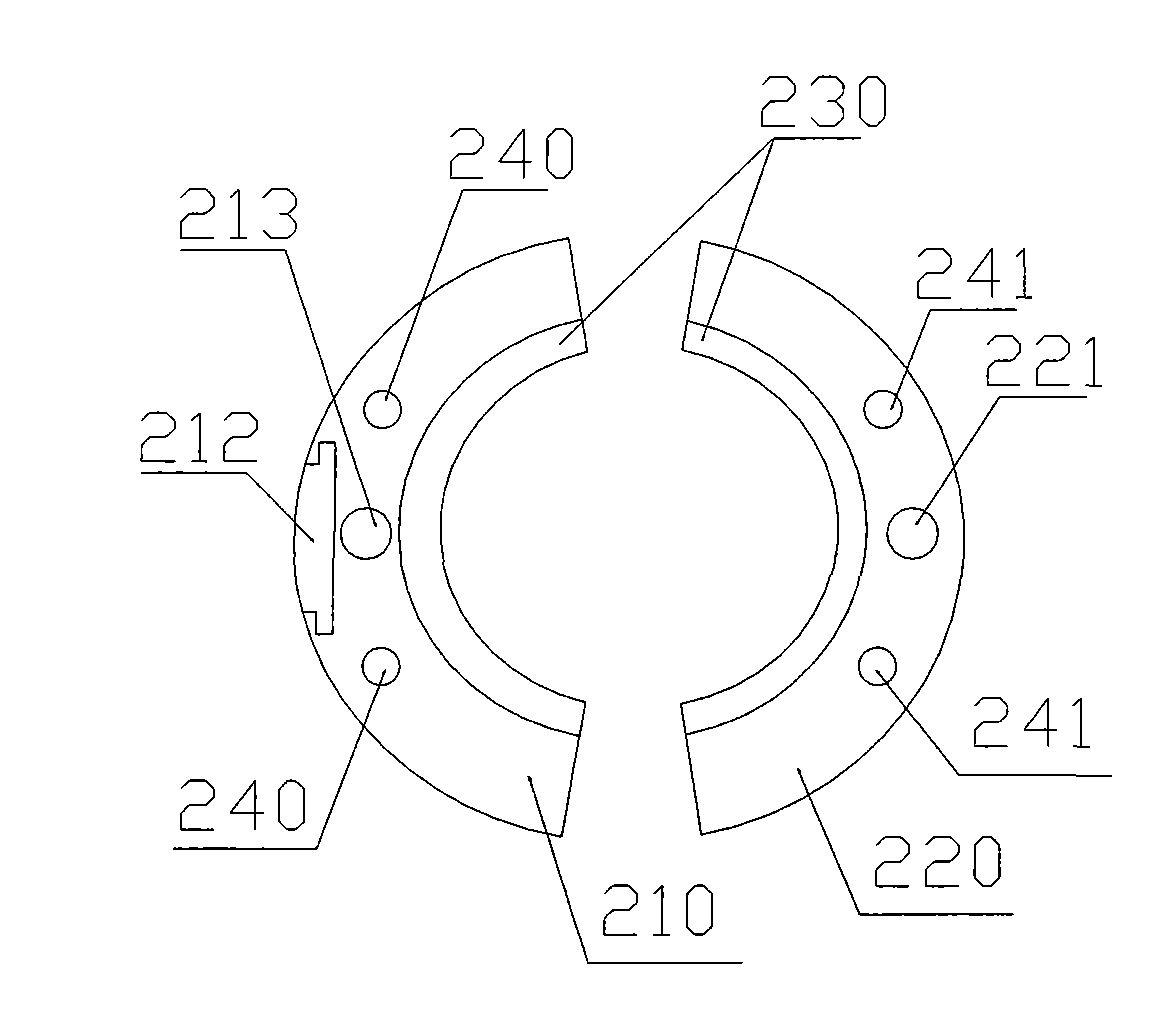

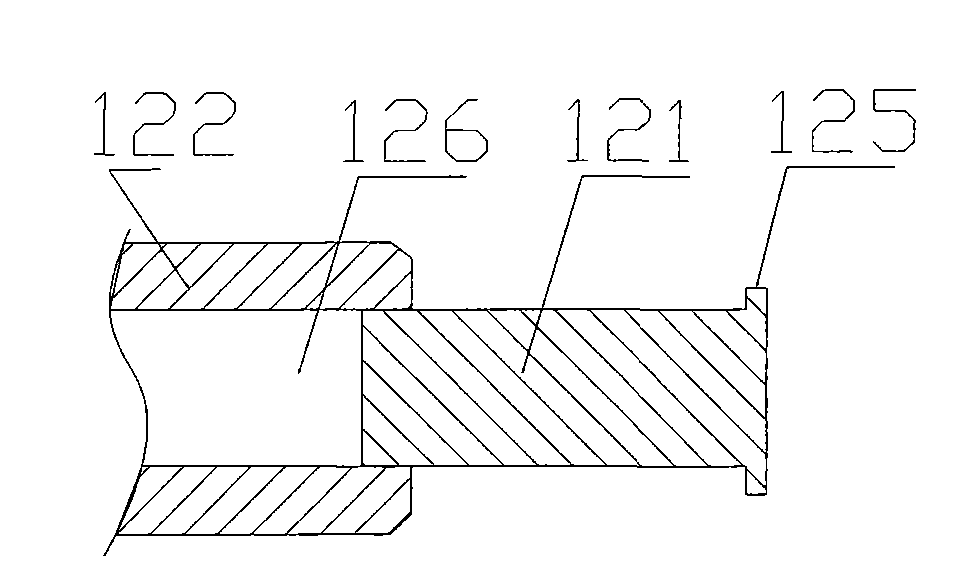

[0021] A tooling fixture, such as figure 1 As shown, it includes a base plate 300, a first clamping block 220 fixed on the base plate 300, a second clamping block 210 slidably arranged on the base plate 300, and driving the second clamping block to face the first clamping block on the base plate. A mobile driving device. The driving device includes a bracket 400, a driving rod, a pressing rod 100, and a connecting rod 140. The bracket 400 is fixedly installed on the base plate 300 and includes a driving rod support 130 for installing the driving rod and a supporting rod. The two parts of the fixed support 150 connecting the tooth rod; one end of the pressure rod 100 is the rotating connection end, at which end is rotatably connected to the fixed support 150 through the first rotating shaft 151, and the other end is the hand-held end; the drive rod 120 is installed on the drive rod The bracket...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com