Polishing slurry for metal chemical mechanical polishing, and use thereof

A chemical mechanical and polishing slurry technology, which is applied in the direction of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., to prevent dielectric erosion, improve product yield, and reduce usage

Inactive Publication Date: 2013-06-12

ANJI MICROELECTRONICS (SHANGHAI) CO LTD

View PDF4 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

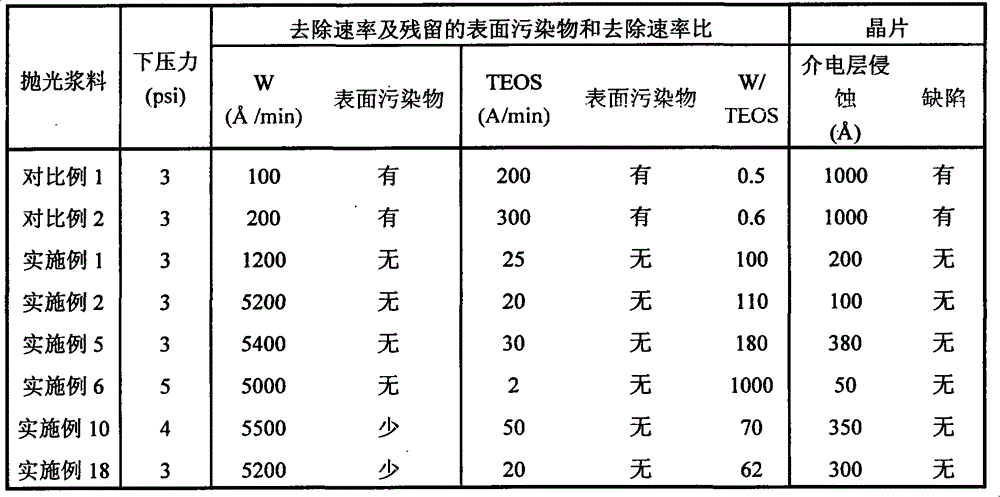

[0004] Therefore, the technical problem to be solved in the present invention is to provide a polishing slurry for metal chemical mechanical polishing and its application in view of the shortcomings of the existing polishing liquid for metal chemical mechanical polishing. The polishing slurry polishes the object Low substrate surface contamination, low dielectric erosion, and high product yield

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1~25

[0021]

[0022] The beneficial effects of the present invention will be further illustrated below through test examples.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses polishing slurry for metal chemical mechanical polishing, and use thereof. The polishing slurry contains oxidants, abrasive particles and a carrier, wherein the oxidants are selected from one or more of permanganic acid, manganic acid and soluble salts thereof, and the polishing slurry preferably comprises one or more water-soluble oxidants of which the oxidation-reductionpotential is higher than divalent manganese ions, except for peroxides. By means of the action of permanganic acid, manganic acid or soluble salts thereof, the polishing slurry produces synergistic effect preferably through the permanganic acid, the manganic acid or the soluble salts thereof and another oxidant to increase the absolute removal rate of metal and reduce the use of polishing particles, thereby reducing cost and the absolute removal rate of dielectric layers and obviously decreasing defects, scratches, stains and other residue. In addition, the polishing slurry has small relativeremoval rate selectivity of dielectric substances during planarization, can prevent dielectric erosion generated during metal planarization, and can improve product yield.

Description

technical field [0001] The invention relates to a polishing slurry, in particular to a polishing slurry for metal chemical mechanical polishing and its application. Background technique [0002] In the integrated circuit (IC) manufacturing process, planarization technology has become one of the indispensable key technologies that are equally important and interdependent with photolithography and etching. The chemical mechanical polishing (CMP) process is currently the most effective and mature planarization technology. The chemical mechanical polishing system is a chemical mechanical planarization technology integrating cleaning, drying, online detection, end point detection and other technologies. An essential technology for improving production efficiency, reducing costs, and global flattening of wafers. CMP is widely used in the field of IC manufacturing, and the polishing objects include substrates, dielectrics and interconnect materials. Among them, metal CMP is one ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): H01L21/304

Inventor 徐春

Owner ANJI MICROELECTRONICS (SHANGHAI) CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com