Chemical mechanical polishing sizing agent

A chemical mechanical and polishing slurry technology, which is applied in the manufacture of polishing compositions containing abrasives, electrical components, and semiconductor/solid-state devices, and can solve problems such as high pinhole corrosion, high dielectric erosion, and low product yield. , to achieve the effect of reducing corrosion, reducing dielectric erosion, and reducing defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~18

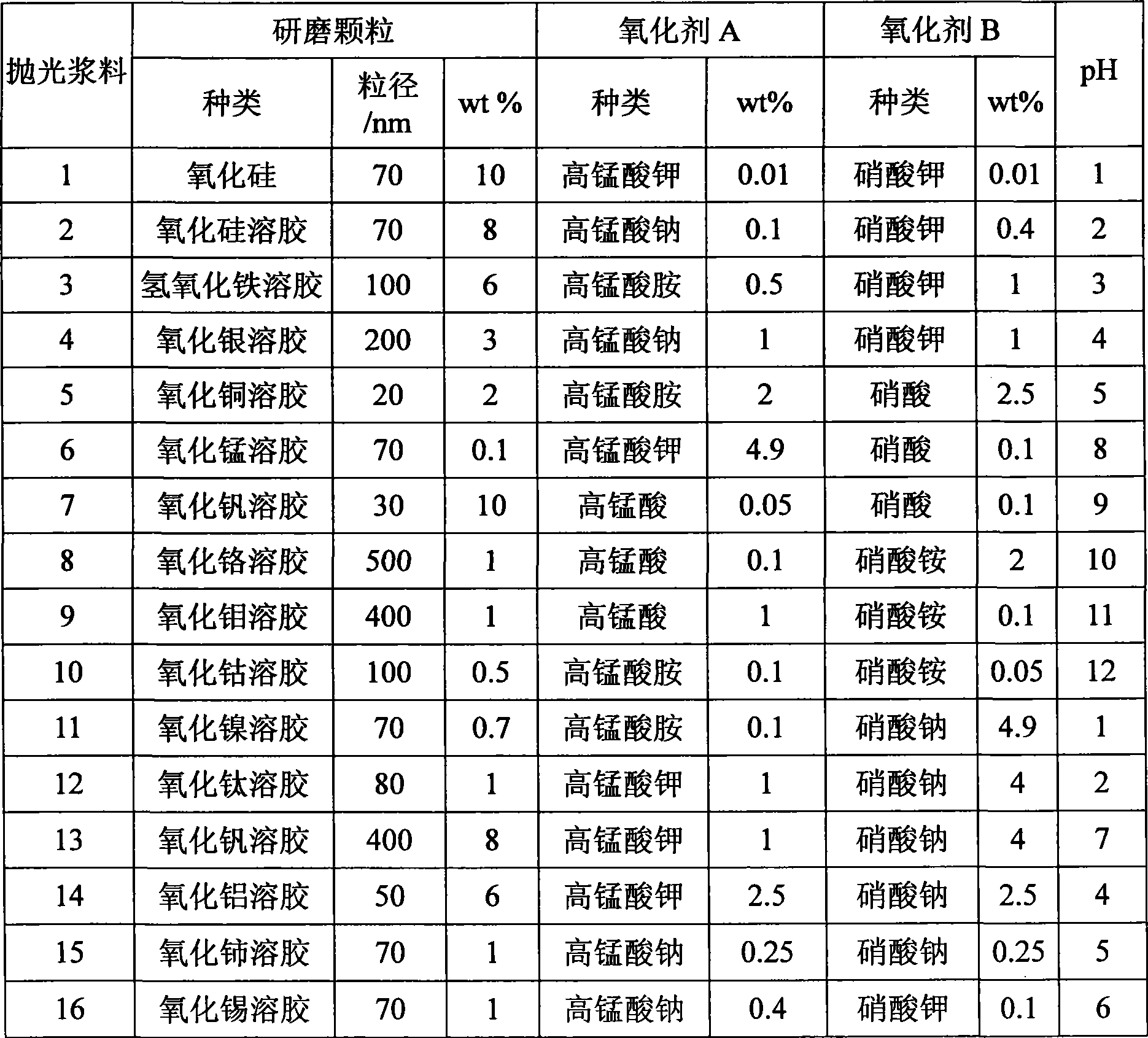

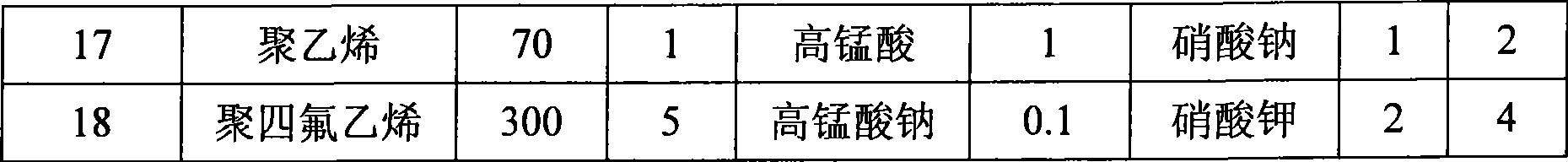

[0016] Table 1 is the chemical mechanical polishing slurry formulation of Examples 1-18. Components and their contents listed in Table 1 are added to the reactor and stirred evenly, adding deionized water to dilute to make up the polishing slurry to a percentage by weight of 100%, and finally using a pH regulator (20% KOH or dilute HNO 3 , select according to the needs of the pH value) adjust to the required pH value, continue to stir until a uniform fluid, and stand still for 30 minutes to obtain the chemical mechanical polishing slurry.

[0017] Table 1. Components and contents of chemical mechanical polishing slurry in embodiments 1 to 18

[0018]

[0019]

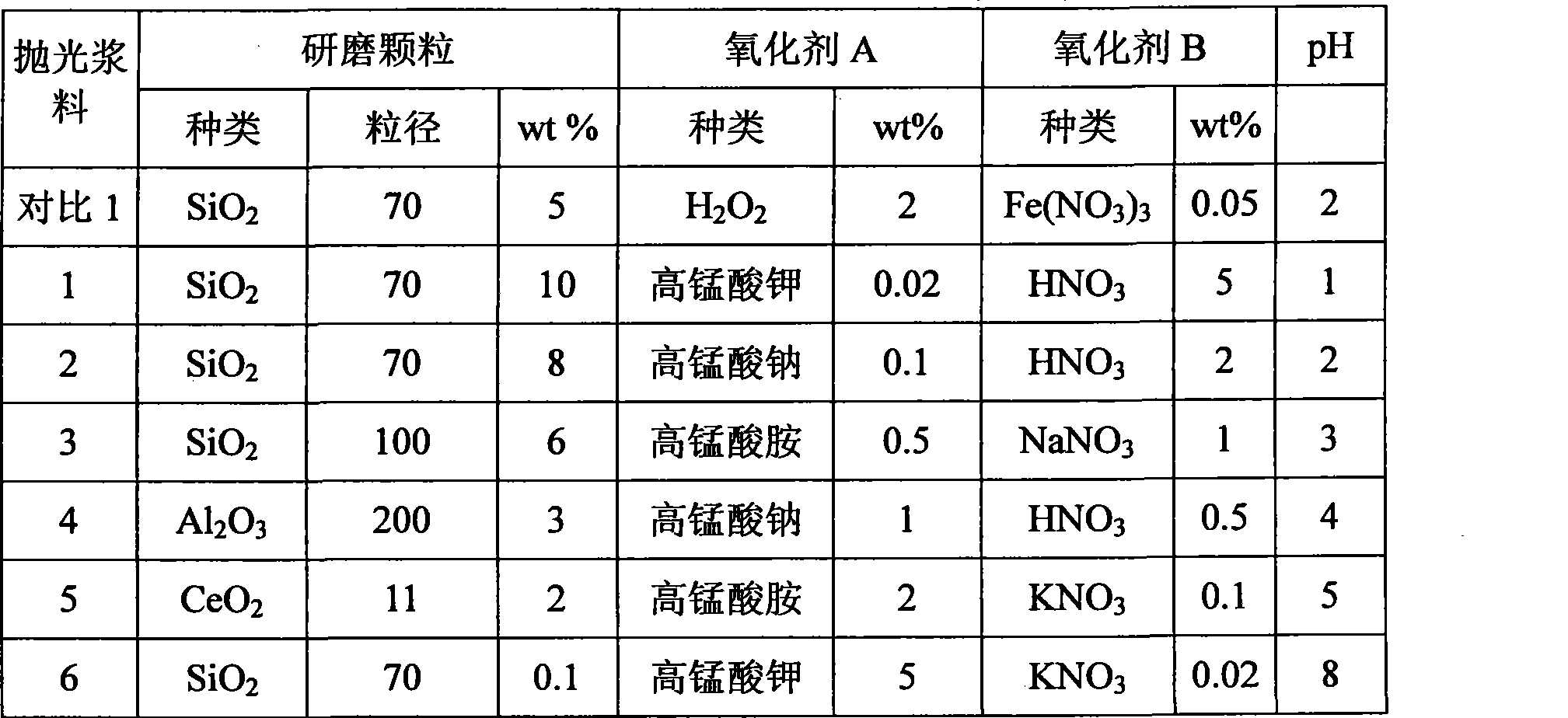

[0020] The beneficial effects of the present invention will be further illustrated below through effect examples.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com