Ice-melting method of transmission line with ends therefore infused with reactive current

A technology for power transmission lines and ice-melting methods, applied in reactive power compensation, cable installation, reactive power adjustment/elimination/compensation, etc., can solve the problems of large-capacity adjustable inductors without molding equipment and large investment in equipment, and achieve Facilitate development and implementation, good economic benefits, clear division of responsibilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

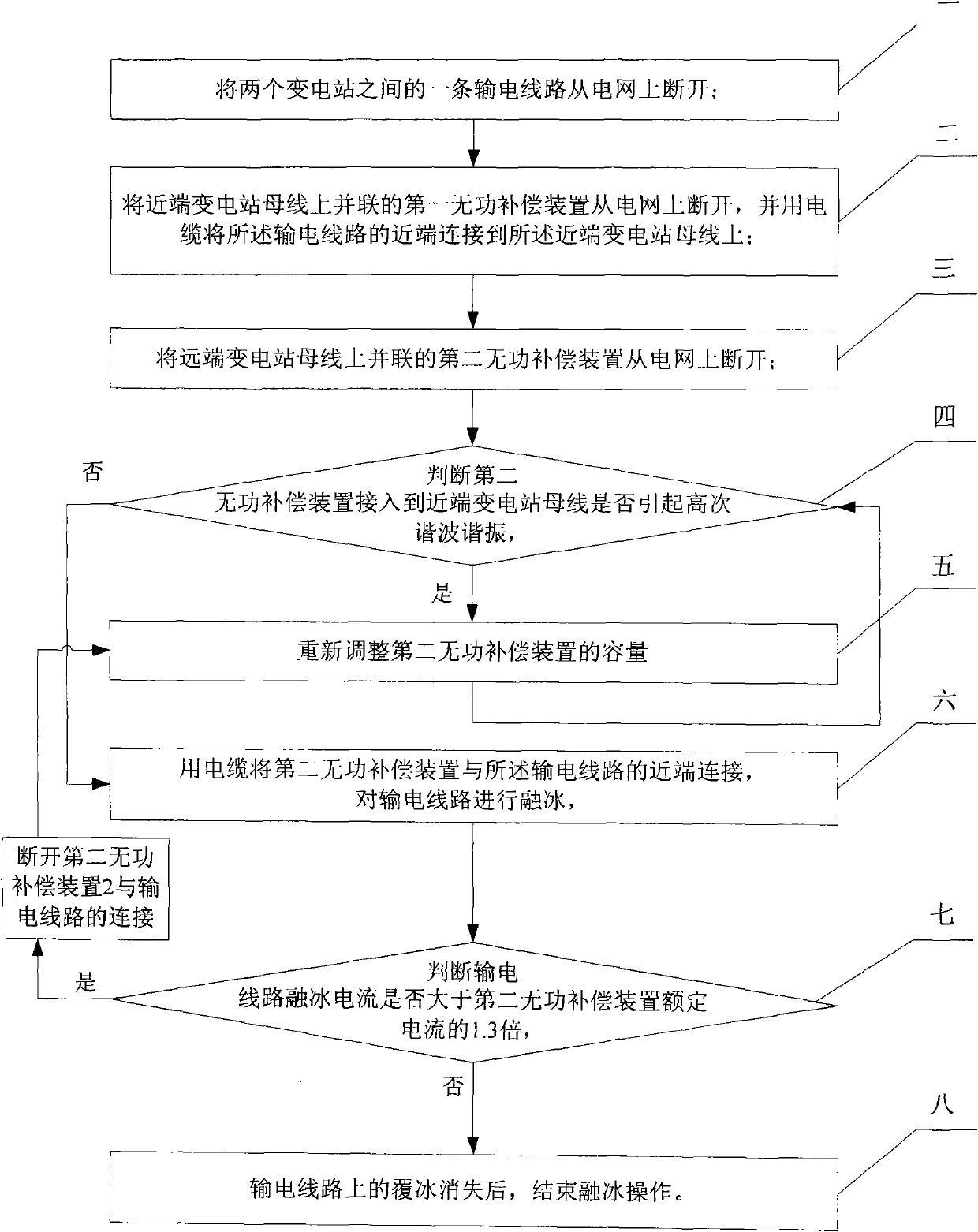

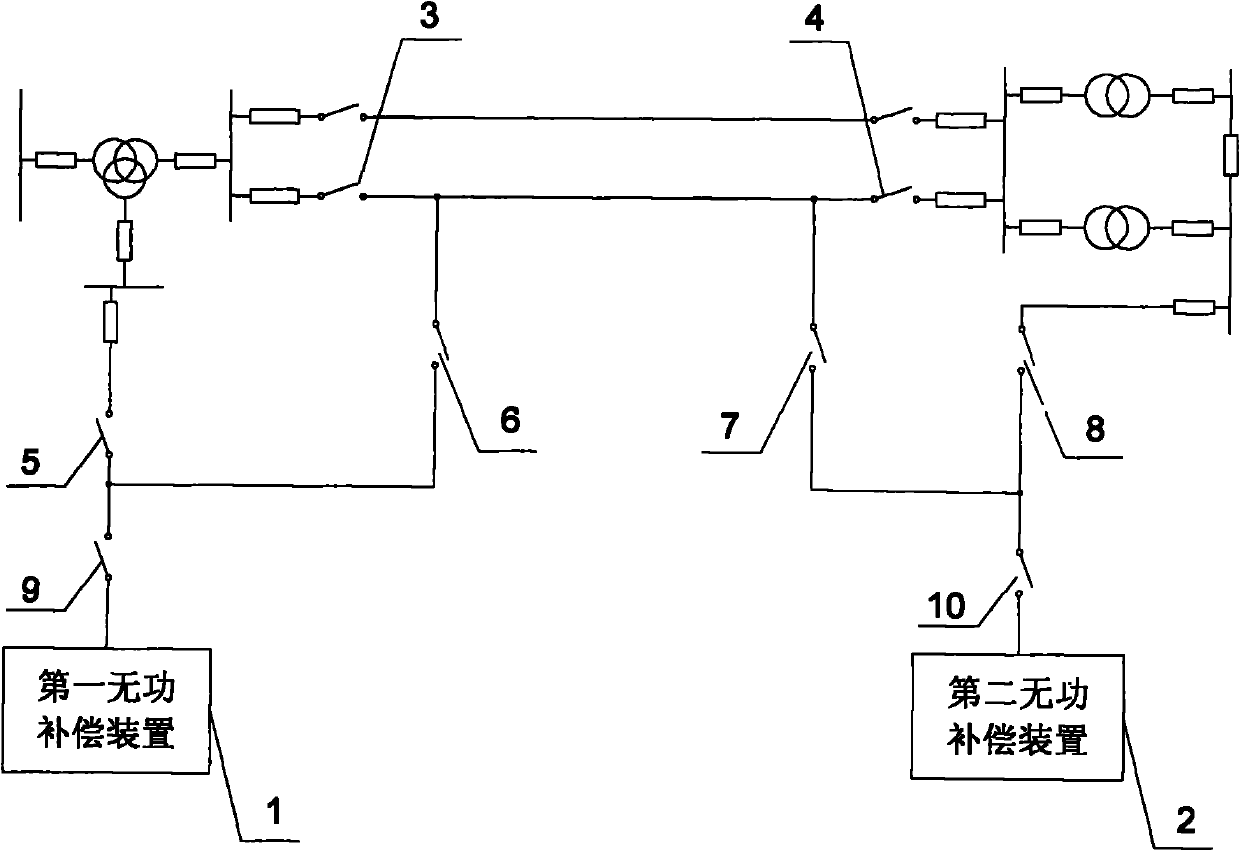

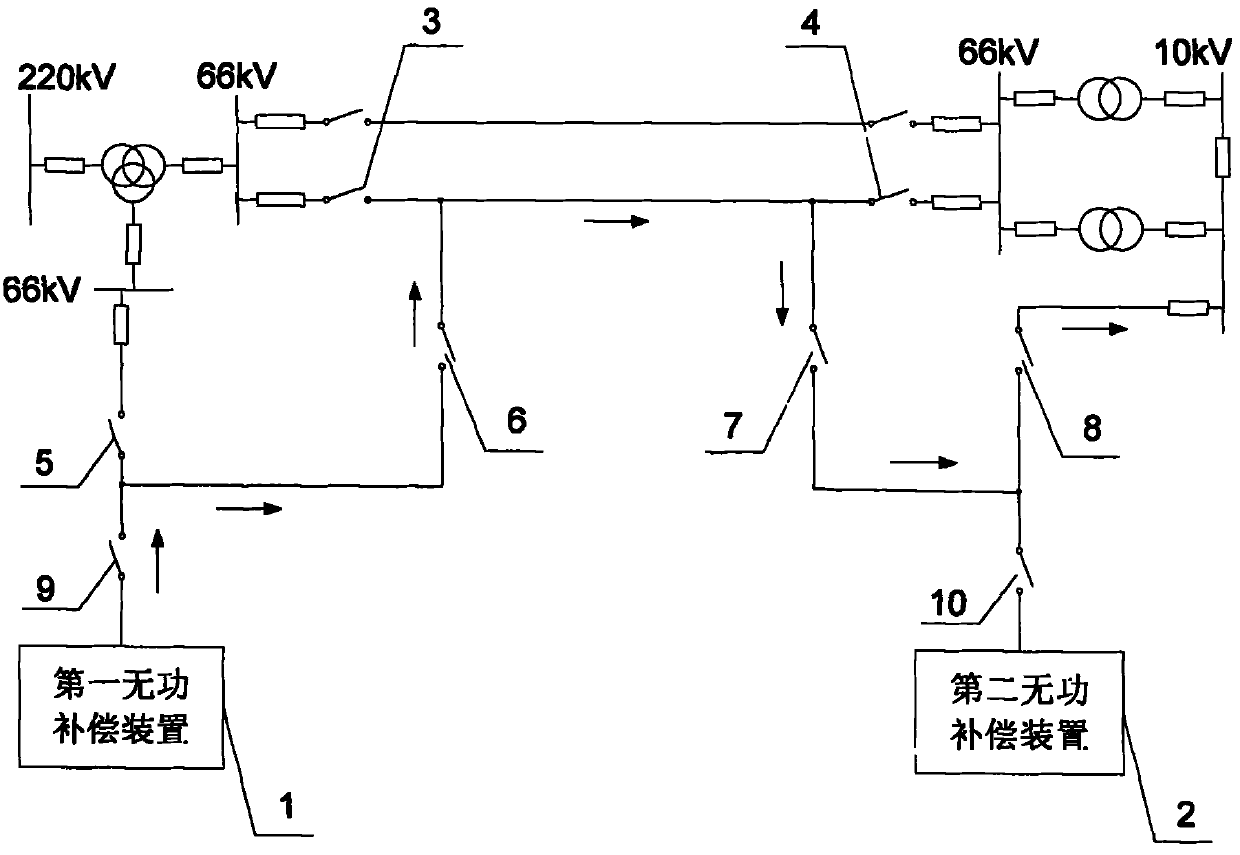

[0027] Specific implementation mode one: the following combination Figure 1 to Figure 5 Describe this embodiment, the method of this embodiment includes the following steps:

[0028] Step 1. Disconnecting a transmission line between two substations from the grid;

[0029] Step 2, disconnect the first reactive power compensation device 1 connected in parallel on the bus of the near-end substation from the grid, and connect the near-end of the transmission line to the bus of the near-end substation with a cable;

[0030] Step 3, disconnecting the second reactive power compensation device 2 connected in parallel on the remote substation busbar from the power grid;

[0031] Step 4, judging whether the connection of the second reactive power compensation device 2 to the near-end substation bus causes high-order harmonic resonance,

[0032] If the judgment result is yes, go to step 5, if the judgment result is no, go to step 6,

[0033] Step five, readjust the capacity of the se...

specific Embodiment approach 2

[0058] Embodiment 2: The difference between this embodiment and Embodiment 1 is that in step 4, the method for judging whether the connection of the second reactive power compensation device 2 to the bus bar of the near-end substation causes high-order harmonic resonance is as follows:

[0059] Calculate the reactive power capacity Q that can cause higher harmonics when connected to the busbar of the near-end substation according to the following formula X :

[0060] Q X = S d ( 1 n 2 - A )

[0061] Among them, S d is the near-end substation bus three-phase short-circuit capacity (MVA);

[0062] A is the inductance of each phase of the second reactive power compensation device 2 (X L ) and capacitive reactance (X C ) ratio,

[0063] That is, A=X L / X C ;

[0064] n is the...

specific Embodiment approach 3

[0067] Specific implementation mode three: the following combination figure 2 and image 3 Describe this embodiment. The difference between this embodiment and Embodiment 1 is that the first reactive power compensation device 1 and the second reactive power compensation device 2 use capacitors, capacitor banks or static var compensators SVC, and others are the same as those of the embodiment. One is the same.

[0068] There is no need to add special ice-melting equipment, such as adjustable reactors, DC rectifier and voltage regulator devices, etc. Capacitors, capacitor banks or static var compensators SVC can be used for connection in the existing power grid, and the reactive current loop input at the end of the line can be formed. De-ice the lines. Save money, manpower and material resources.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com