De-icing device with wattless current injected in the end of transmission line

A transmission line and ice melting technology, which is applied in the installation of cables, electrical components, overhead installation, etc., can solve the problems of large-capacity adjustable inductance without forming equipment and large equipment investment, and achieves favorable development and implementation, and good economic benefits. , good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

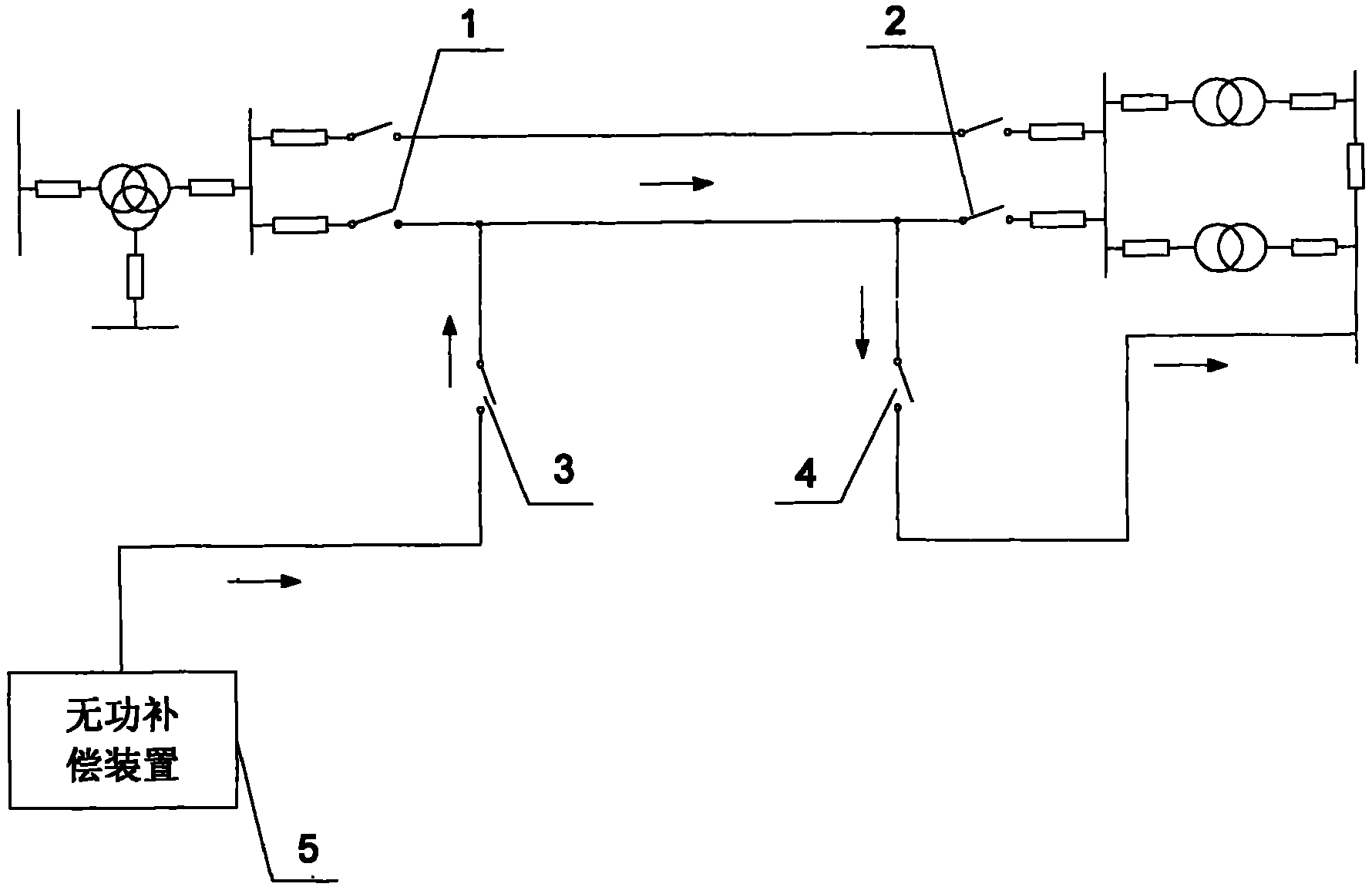

[0017] Specific implementation mode one: the following combination figure 1 Describe this embodiment, this embodiment includes a first isolating switch 1 and a second isolating switch 2, the two ends of the transmission line are respectively provided with the first isolating switch 1 and the second isolating switch 2, and it also includes a near-end deicing isolating switch 3 , the far-end ice-melting isolating switch 4 and the reactive power compensation device 5, the reactive power compensating device 5 is connected to one end of the near-end ice-melting isolating switch 3, and the connection point between the first isolating switch 1 and the near-end of the transmission line is connected to the ice-melting isolating switch The other end of 3 is connected, the connection point between the second isolating switch 2 and the far end of the transmission line is connected to one end of the remote deicing isolating switch 4, and the other end of the remote deicing isolating switch ...

specific Embodiment approach 2

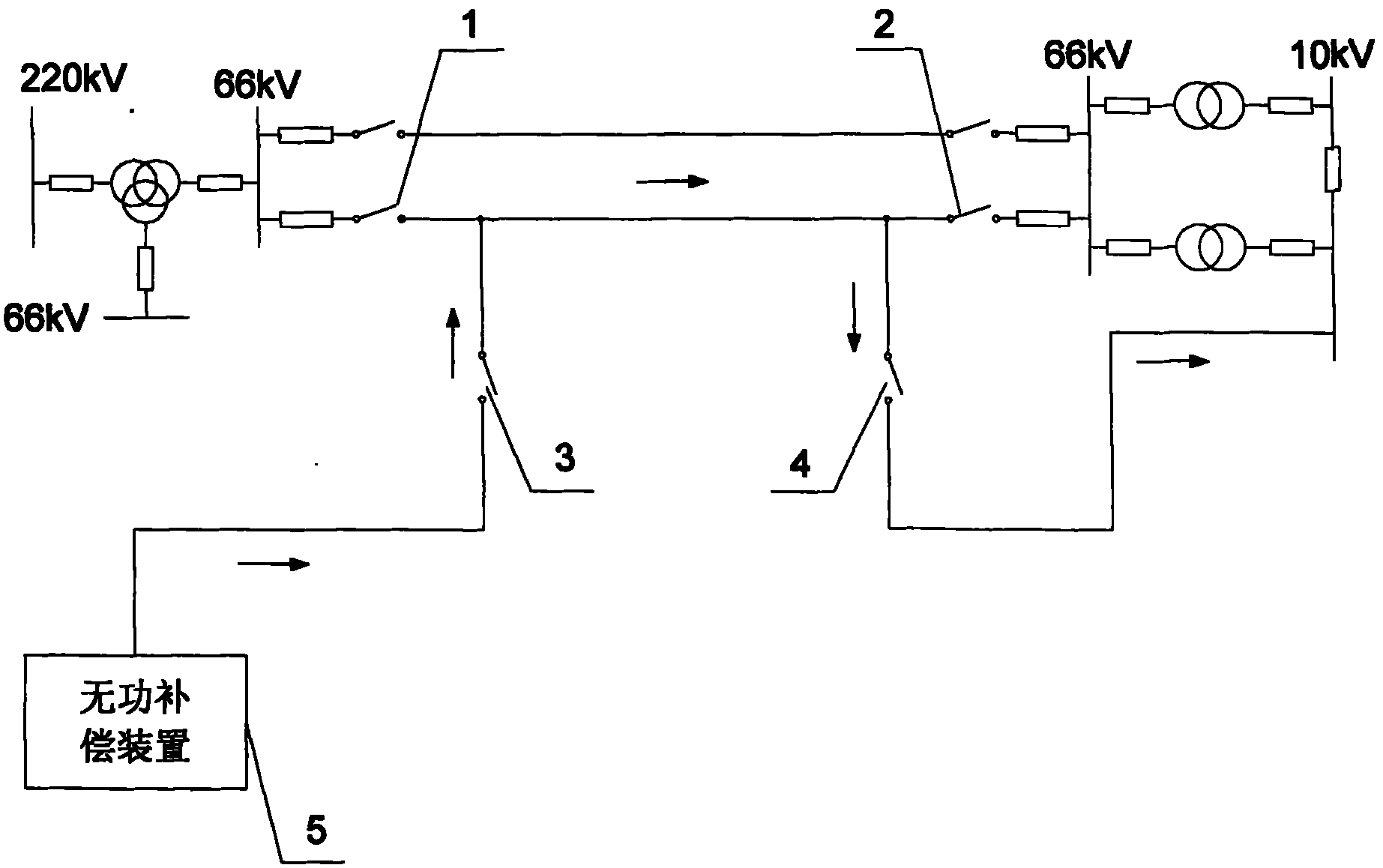

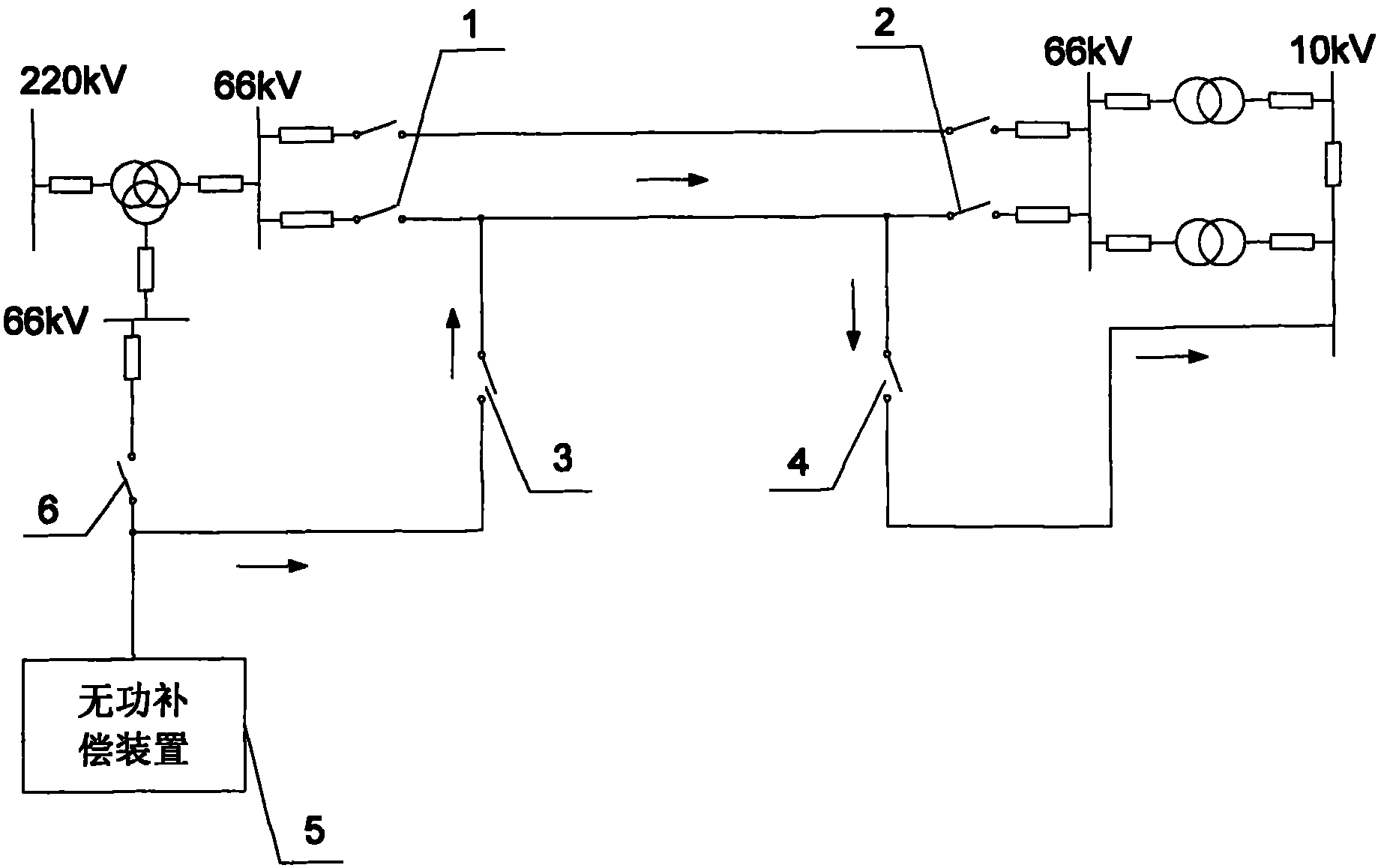

[0018] Specific implementation mode two: the following combination Figure 2 to Figure 5 This embodiment is described. The difference between this embodiment and the first embodiment is that the reactive power compensation device 5 uses a capacitor, a capacitor bank or a static var compensator SVC, and other components and connections are the same as those of the first embodiment.

[0019] The transmission line refers to the transmission line between two substations. In this embodiment, the reactive power compensation device 5 adopts a capacitor, a capacitor bank or a static var compensator SVC connected in parallel on the busbar of the near-end substation, that is, the near-end substation The reactive power compensation device 5 originally used to improve the power factor is connected to the remote substation for melting ice of the transmission line. In this way, there is no need to add special ice melting equipment, such as adjustable reactors, DC rectifying and voltage regul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com