Switching rocker of a shifting device for a gear wheel gear change box and corresponding production method

A technology of variable speed gearbox and shifting device, which is applied in the field of transmission system, can solve the problems of high cost and time-consuming, and achieve the effect of saving time and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

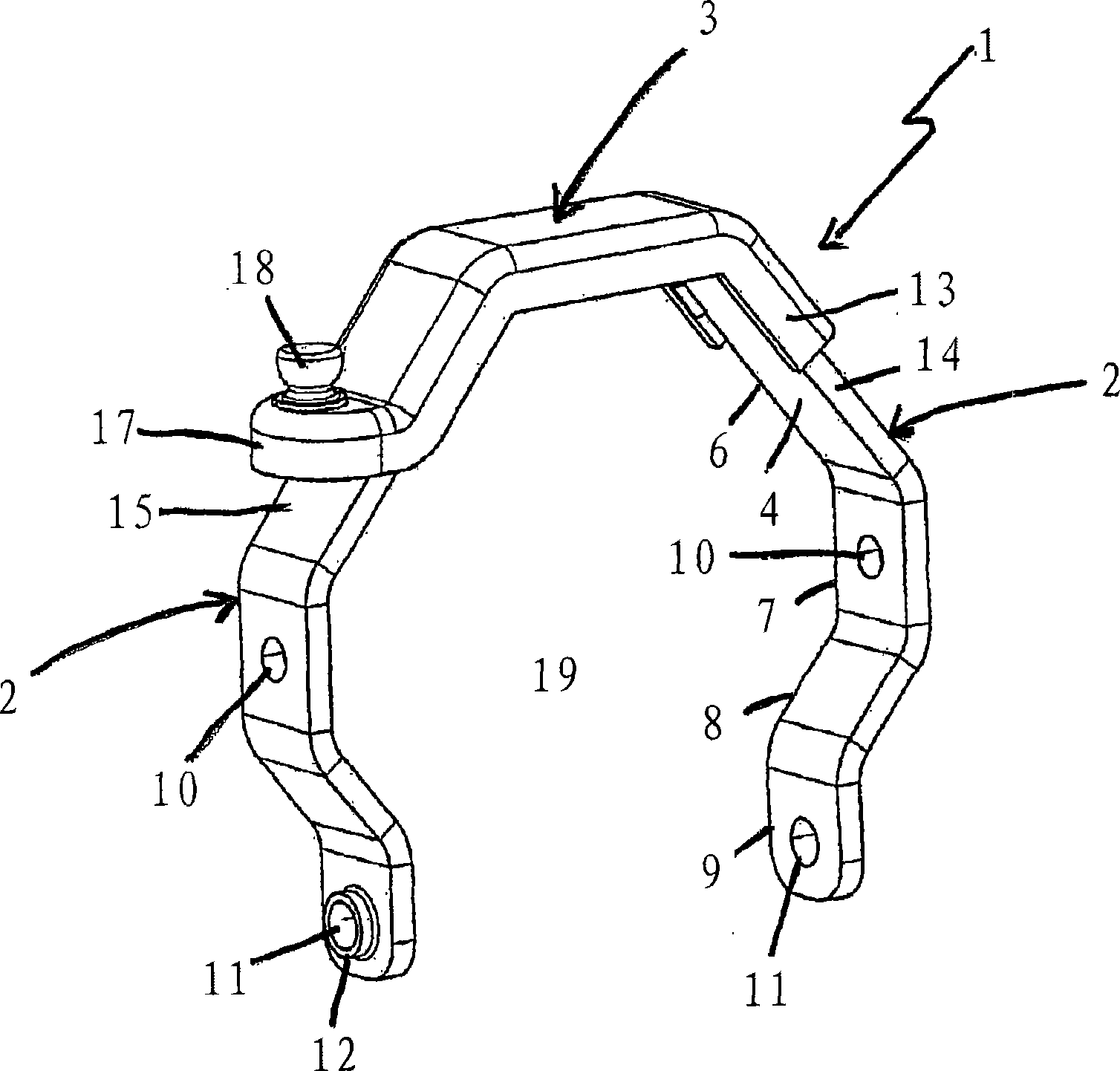

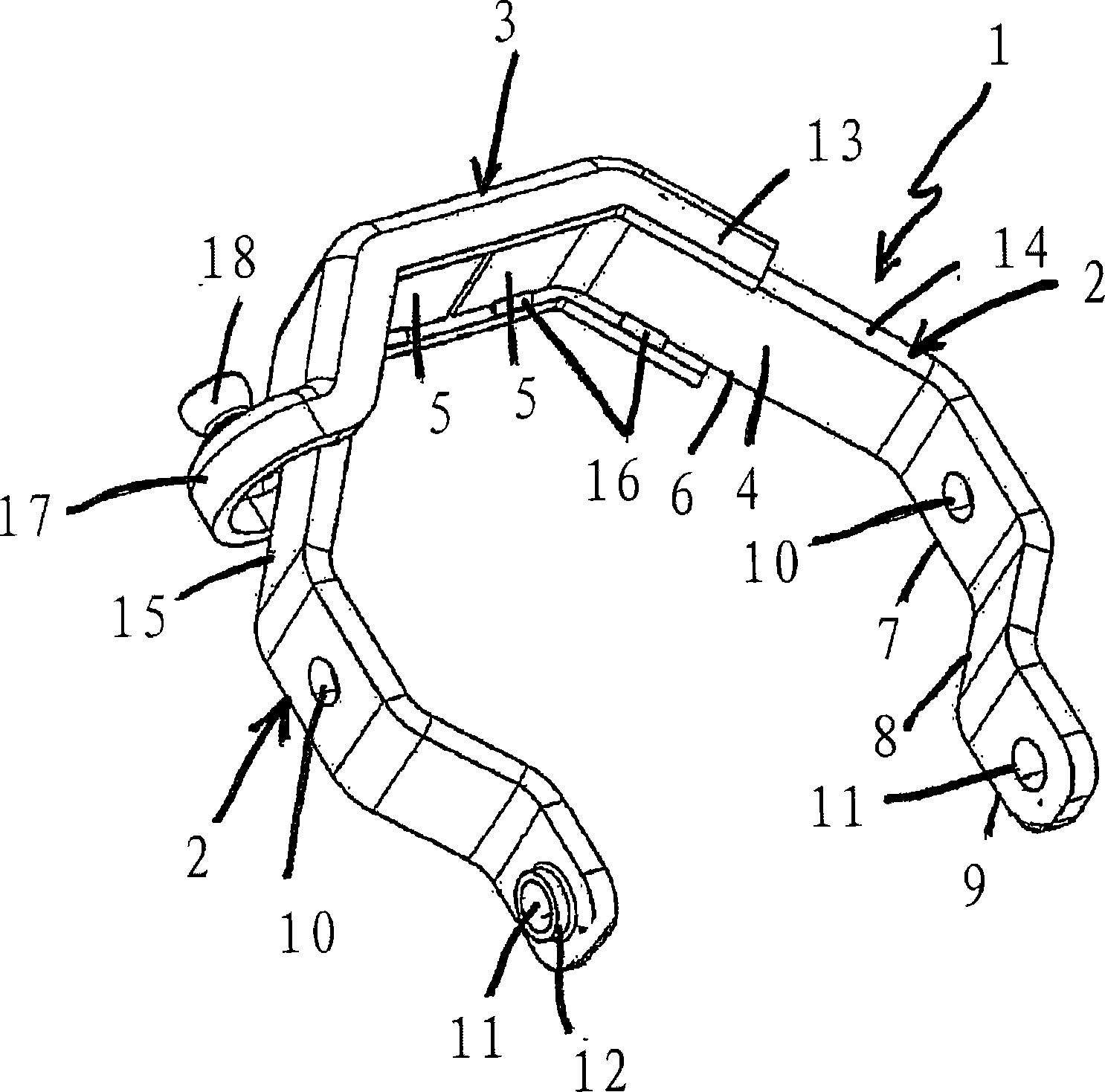

[0025] right now figure 1 and figure 2 An explanation is given in which an exemplary embodiment of a gearshift rocker according to the invention is explained.

[0026] Correspondingly, the shift rocker, which is designated together with the reference numeral 1, is composed of two half parts 2 of the same type and a connecting element 3 which firmly connects the two half parts 2 to one another.

[0027] Each half-part 2 has a curved spatial structure which is formed from a slightly elongated flat material, for example consisting of sheet steel. To this end, several bending operations are required, in which the different profiled sections of the flat material are hemmed by forces acting on the wide forming surfaces 4 and 15 in a direction perpendicular to the longitudinal direction of the flat material.

[0028] The effect of a bending process is thus to curl the first end profiled section 5 relative to the second profiled section 6 in the direction of bending. The further b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com