Cutting device

A desktop cutting machine, cutting machine technology, applied in the direction of sawing equipment, metal sawing equipment, sawing machine equipment, etc., can solve the problems of cumbersome locking and unlocking operations of sliding locking mechanisms, etc., to improve operability and improve operability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

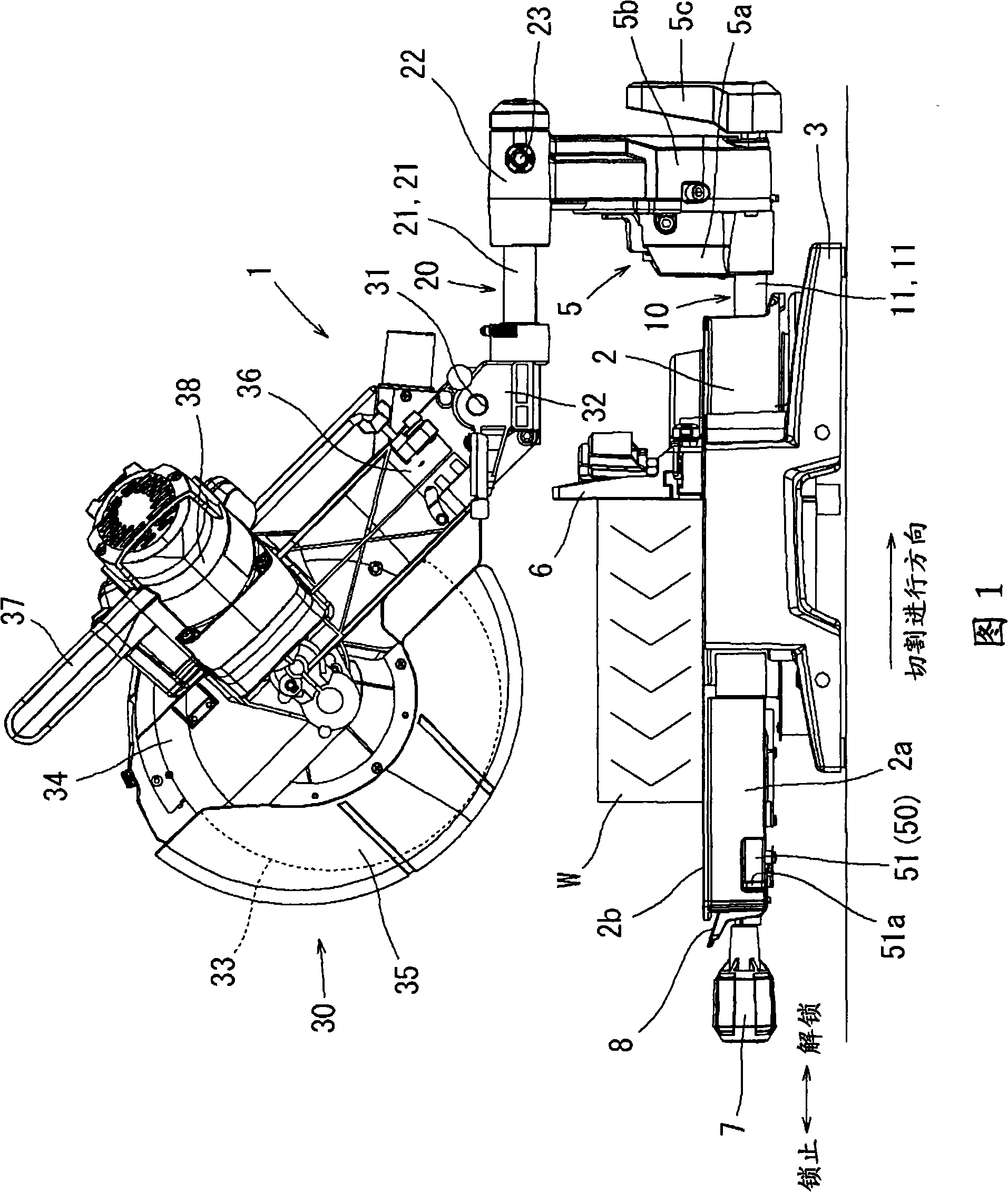

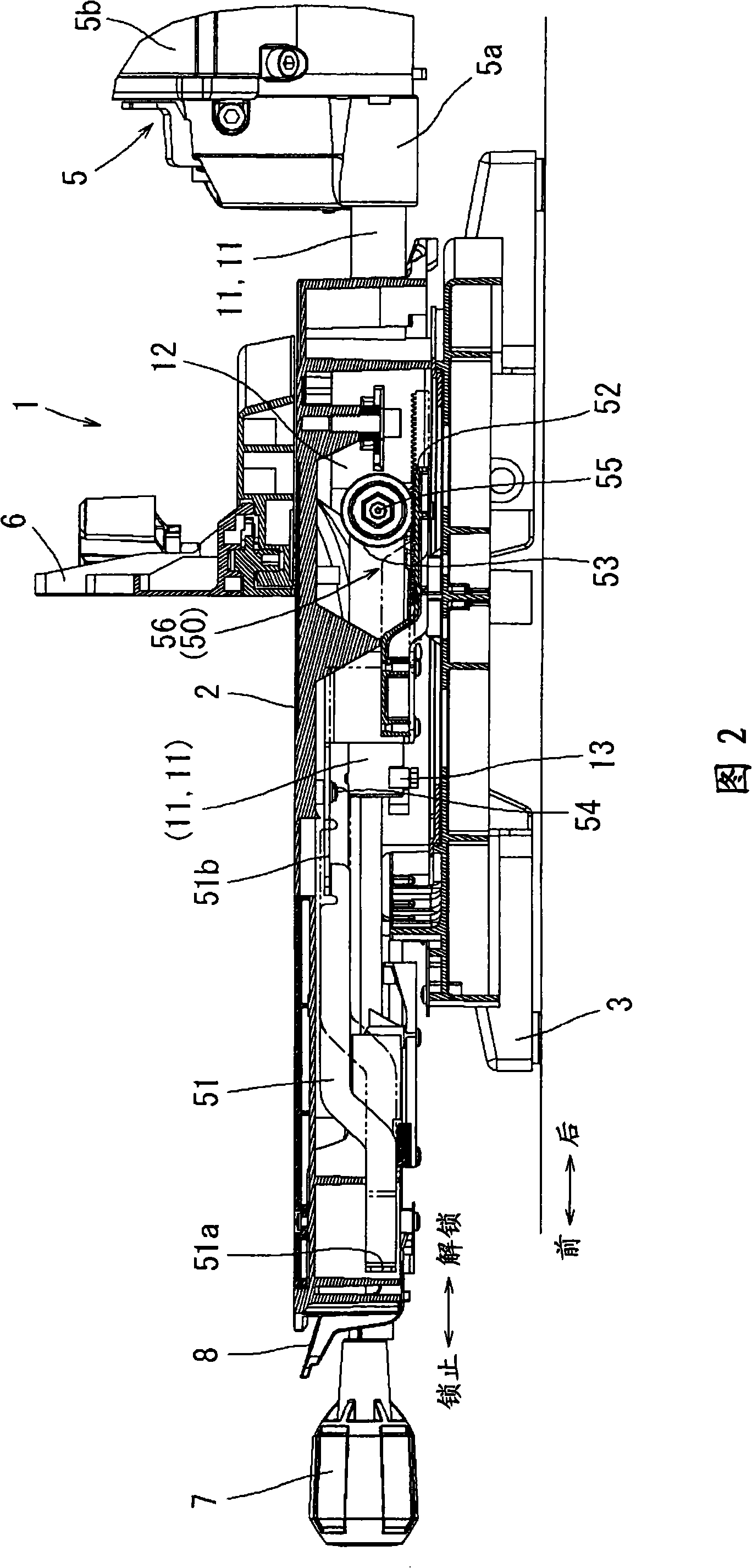

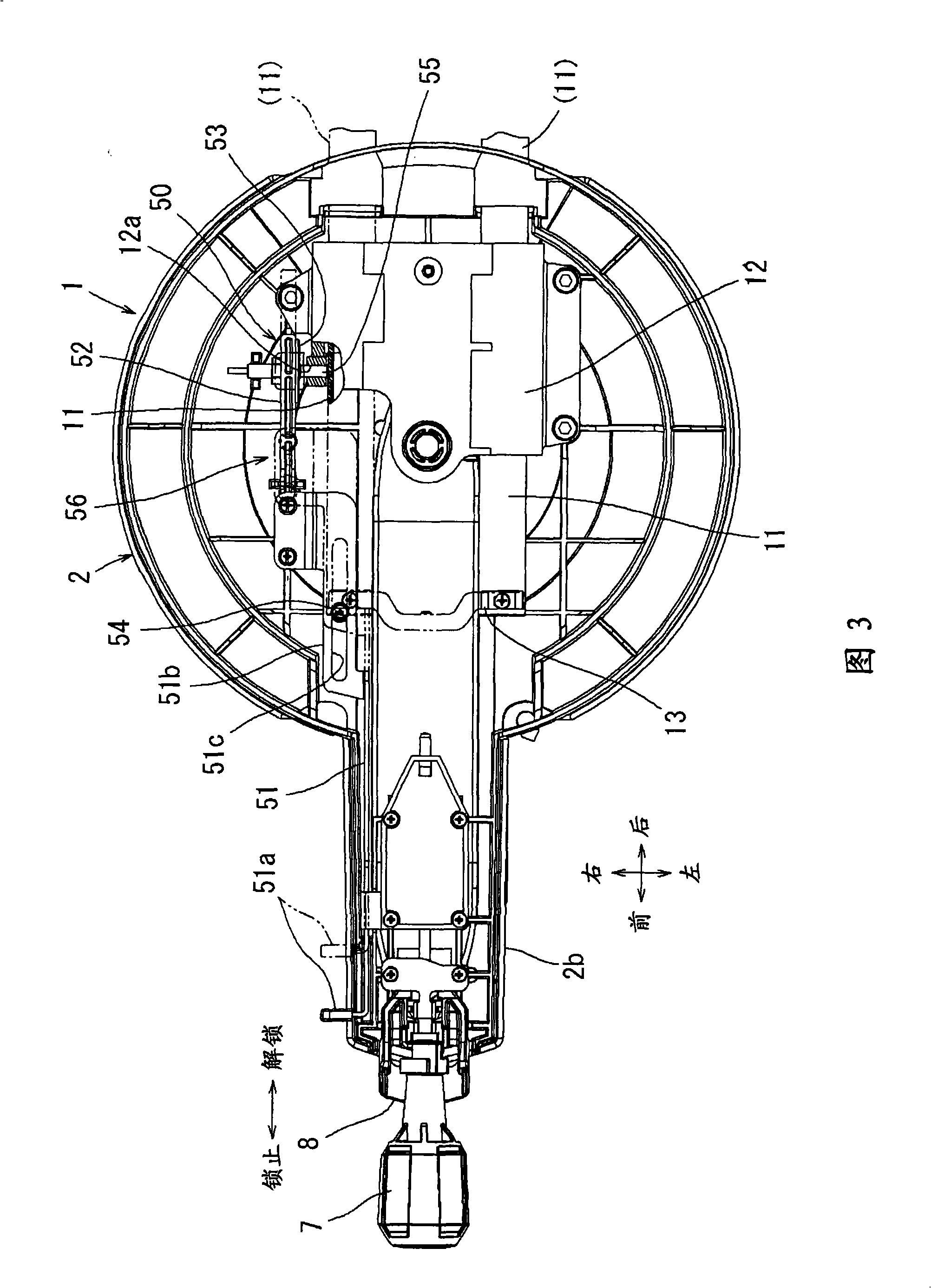

[0033] Next, specific embodiments of the present invention will be described with reference to FIGS. 1 to 8 . FIG. 1 shows the whole of a desktop cutting machine 1 in this embodiment. As shown in FIG. 1 , the user performs various operations on the desktop cutting machine 1 on the left side of the desktop cutting machine 1 . After the user moves the cutter body 30 downward, the user moves the cutter body 30 from the left side (closer side) to the right side in FIG. 1 to cut the workpiece W to be cut. Hereinafter, the direction in which dicing is performed is simply referred to as the direction in which dicing is performed. However, the front-back direction of components etc. is based on the user. Therefore, let the left side (the user's side) in FIG. 1 be the front side (close body side), and the right side in FIG. 1 be the rear side. In addition, the left-right direction of components etc. is based on the direction seen by a user.

[0034] The desktop cutting machine 1 ha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com