Processing method for increasing stripping resistance of sealed periphery of diaper

A processing method and anti-peeling technology, applied in the field of personal hygiene products, can solve the problems of sticky diaper products, glue exudation, inability to lock the cotton core, etc., and achieve the effect of increasing the anti-peeling force and maintaining the comfort of use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

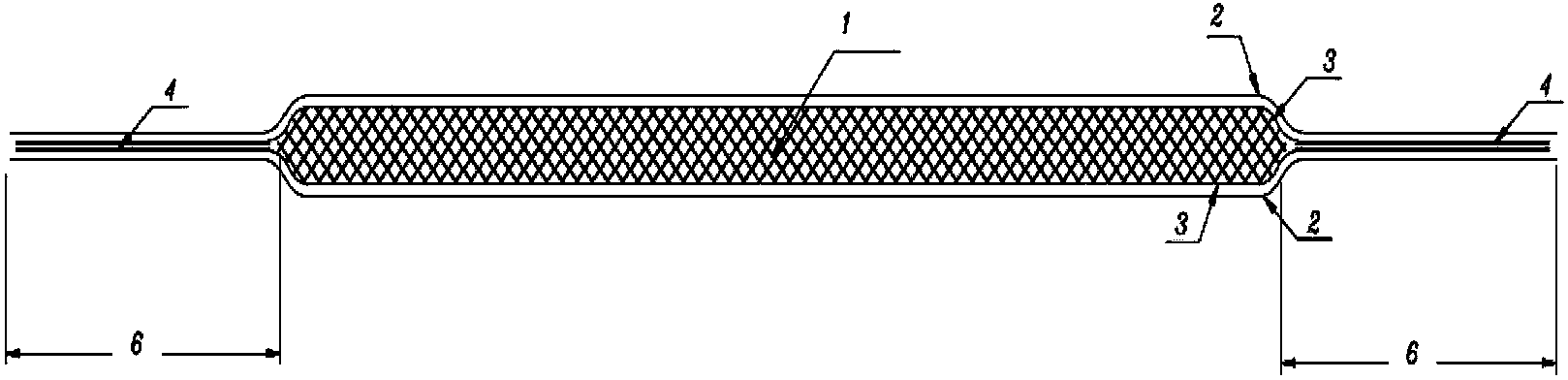

[0011] like figure 1 , the present invention is a processing method for increasing the anti-peeling force of the diaper peripheral seal, which includes making the diaper cotton core 1 by wrapping wood pulp fiber with ultra-thin non-woven fabric 3 and adding a high proportion of high-molecular water-absorbing material. The four sides of the non-woven fabric 3 are extended to the peripheral sealing area 6 of the diaper, and the ultra-thin non-woven fabric 3 in the peripheral sealing area 6 of the diaper is coated with hot melt adhesive for bonding; the cotton core of the diaper wrapped by the ultra-thin non-woven fabric 3 The body 1 is wrapped up and down by the bottom and surface layer non-woven fabric 2, and the bottom and surface layer non-woven fabric 2 are located in the diaper peripheral sealing area before wrapping. 6. Under the combined action of the heat sealing by the sealing roller and the bonding of the hot melt adhesive, the ultra-thin non-woven fabric 3 in the peri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com