Printing floor and production method thereof

A printing flooring and production method technology, applied in coating, construction, manufacturing tools, etc., can solve the problems of decreased adhesion, poor interlayer adhesion, unstable pattern color, etc., and achieve the effect of color stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The printed floor and its production method of the present invention will be further described in detail below in conjunction with specific examples.

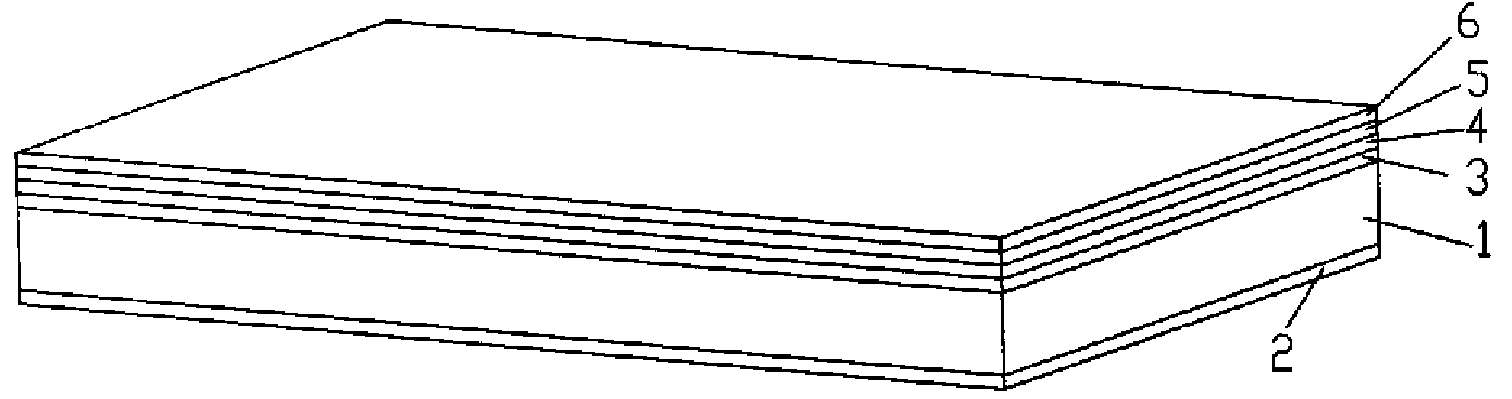

[0028] Such as figure 1 Shown is the printed floor of the present invention, comprising a floor substrate 1, the back of the floor substrate is coated with an anti-shrinkage primer layer 2 formed of a flexible polymer composition, and the surface of the floor substrate 1 is coated with a flexible polymer The anti-shrinkage primer layer 3 formed by the composition, the pattern layer 4 is printed on the anti-shrinkage primer layer 3, and the anti-shrinkage primer layer 5 formed by the flexible polymer composition is coated on the surface of the printed pattern layer 4, the anti-shrinkage primer layer A topcoat layer 6 is arranged on the paint layer 5, and the topcoat layer 6 is a transparent wear-resistant paint.

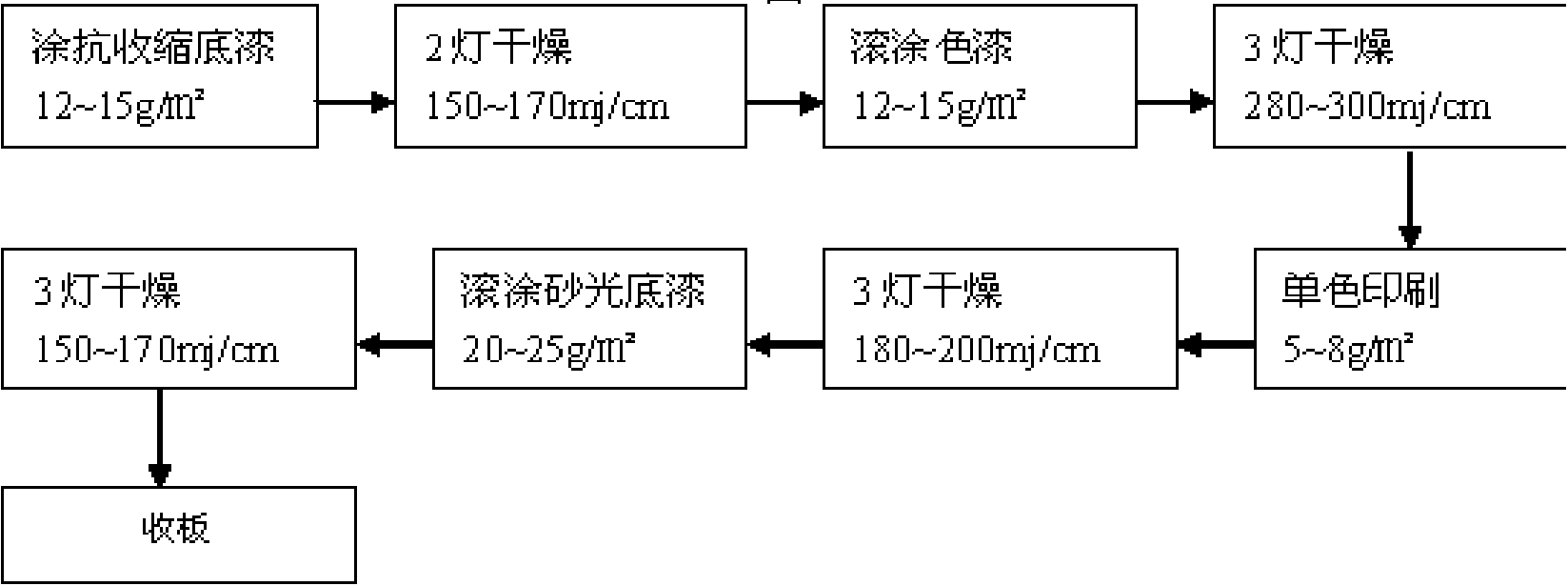

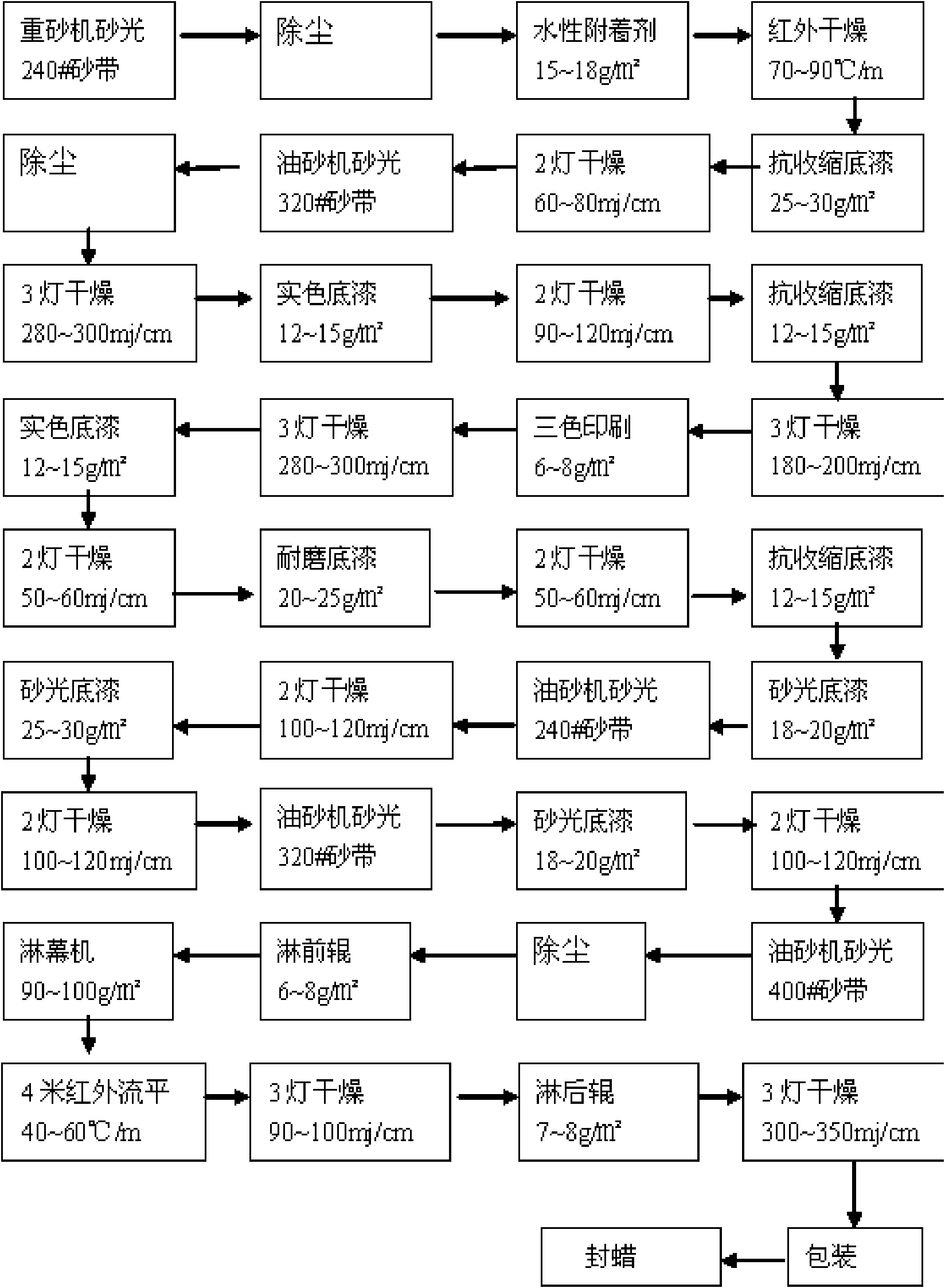

[0029] The production method of printed floor of the present invention is as follows:

[0030] 1. The proce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com