Brush manufacturing machine for circular brush

A technology for making machines and circular brushes, applied in the direction of brushes, applications, brush bodies, etc., can solve the problem of expensive devices, and achieve the effects of shortening manufacturing time, simple and rapid processing, and avoiding time loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

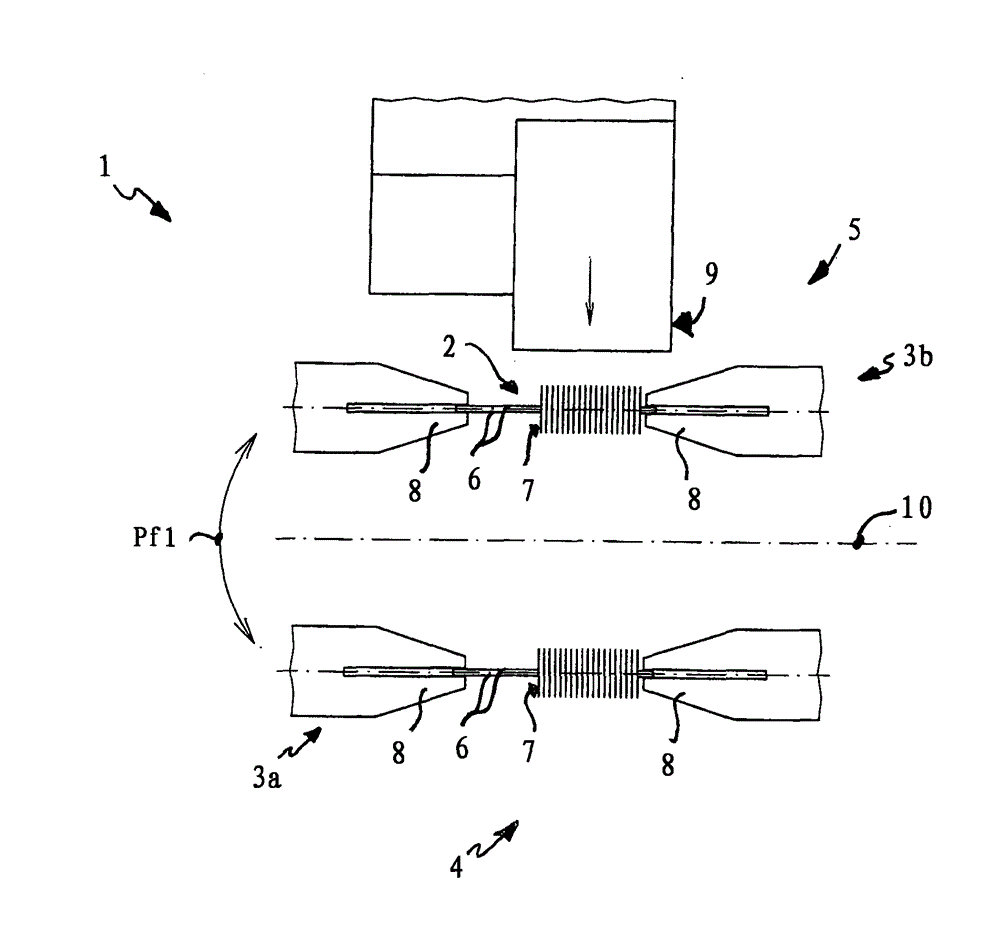

[0027] exist figure 1 The brush manufacturing machine 1 for round brushes 2 shown in a very simplified manner has two wire twisting devices 3a, 3b, which are mounted rotatably (arrow PF1) on Between an insertion position 4 and a processing position 5 .

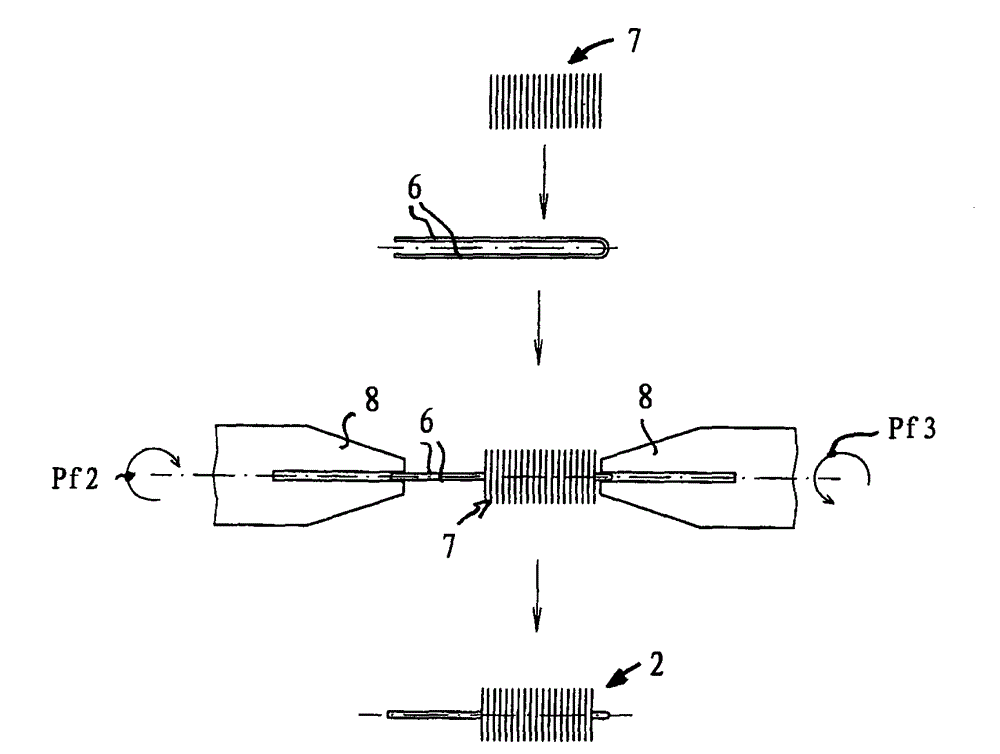

[0028] On the insertion position 4, the metal wire 6 and the bristle wire 7 ( figure 2 ) into the wire twisting device 3a located there ( figure 1 ). The two wire twisting devices 3a, 3b each have two grippers 8 spaced apart from each other, by means of which the wires are clamped. The grippers 8 are respectively driven by a servomotor not shown, wherein the two grippers 8 of the wire twisting devices 3a, 3b are positioned according to the arrows Pf2 and Pf3 figure 2 in the opposite rotational motion.

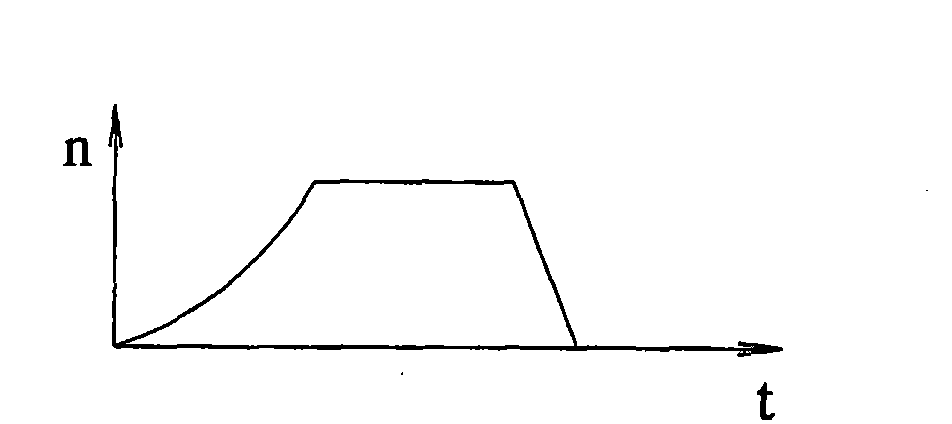

[0029] The servomotor is initially operated at a low rotational speed in order to prevent individual bristle filaments 7 from falling out. As soon as the bristle filaments 7 are securely clamped between the wires 6 , th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com