Spacer for insulated glazing

A technology for retaining parts and glass, applied in the direction of parallel glass structures, building components, windows/doors, etc., can solve the problems of increasing material costs and manufacturing costs, and achieve the effect of weight reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

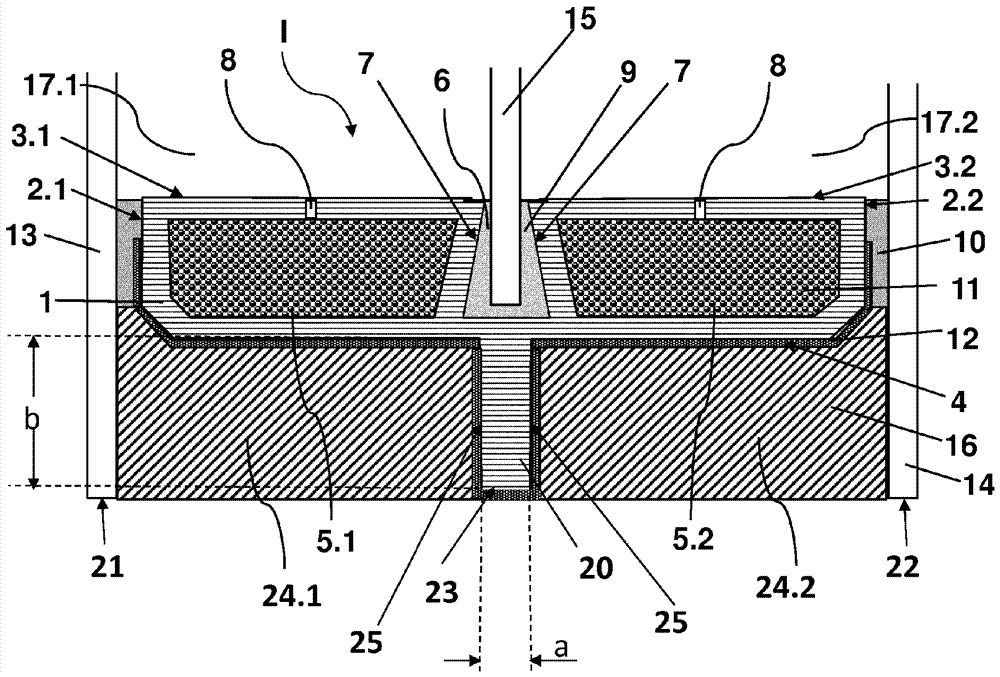

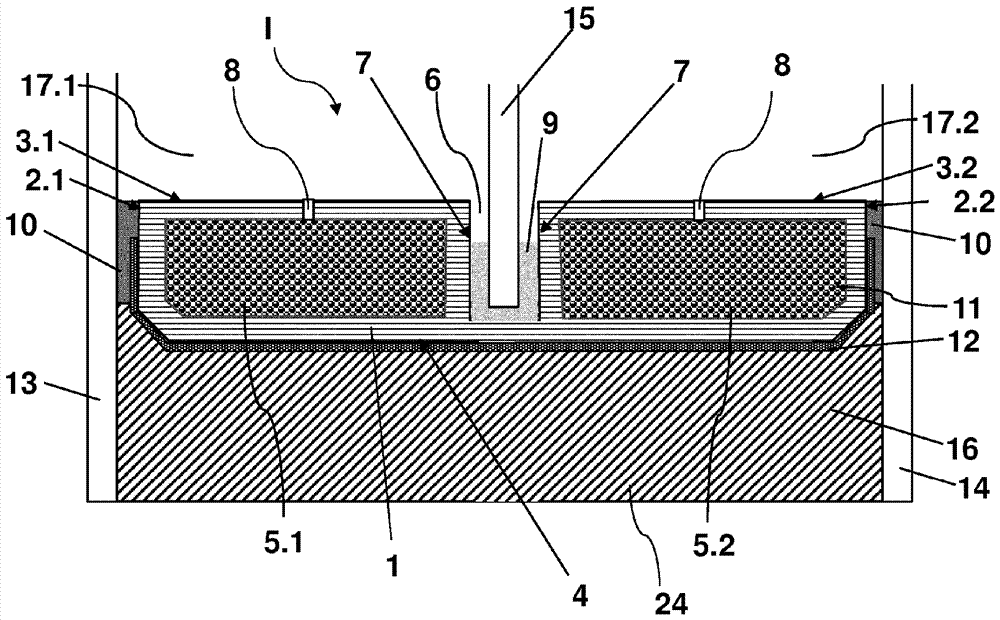

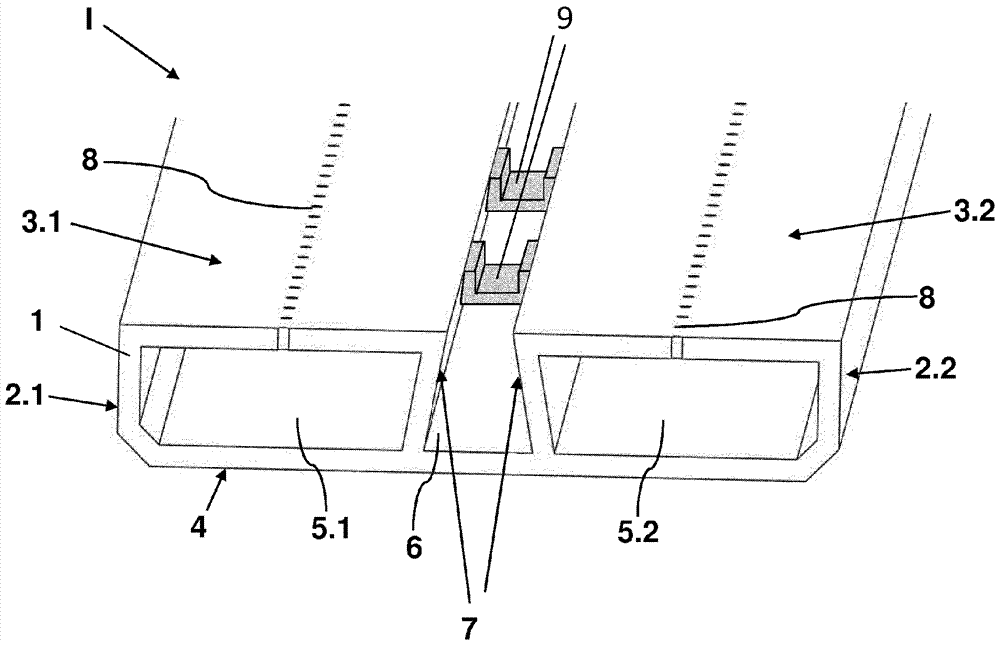

[0074] figure 1 A cross section of a spacer I according to the invention is shown. The glass fiber reinforced polymer matrix 1 comprises a first sheet contact surface 2.1, a second sheet contact surface 2.2 extending parallel to the first sheet contact surface 2.1, a first glass unit interior space surface 3.1, a second glass unit Inner space surface 3.2 and outer surface 4. Between the outer surface 4 and the first glazing unit interior surface 3.1 there is a first cavity 5.1, while a second cavity 5.2 is arranged between the outer surface 4 and the second glazing unit interior surface 3.2. Between the two cavities 5.1 and 5.2 there is a notch 6 which runs parallel to the sheet contact surfaces 2.1 and 2.2. In this case, the side wall 7 of the slot 6 is formed by the walls of the two cavities 5.1 and 5.2, while the bottom of the slot 6 adjoins the bridge. The side walls 7 of the slot 6 slope inwardly in the direction of the sheet to be accommodated in the slot 6 . A narro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com