Valve cartridge with low point of contact for installation

A technology of spool and shell, applied to multi-way valves, valve devices, valve details, etc., can solve the problems of less freedom and increased cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] While the general concepts of the invention are susceptible of embodiments in many different forms, specific embodiments thereof are shown in the drawings and will be described in detail herein, it being understood that this disclosure is to be considered in accordance with the principles of the general concepts of the invention. for example. Therefore, the general concepts of the invention are not to be limited by the specific embodiments described herein.

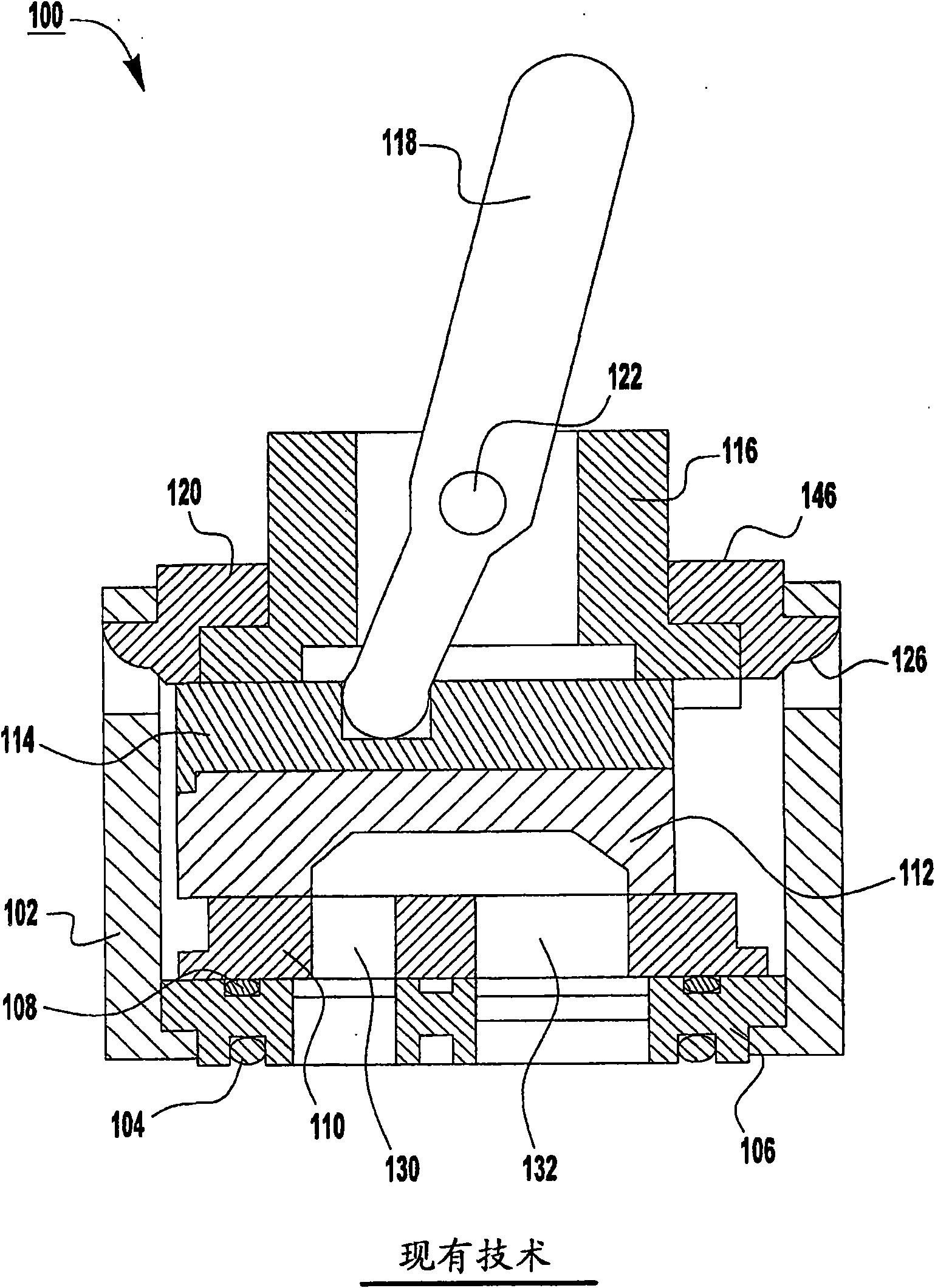

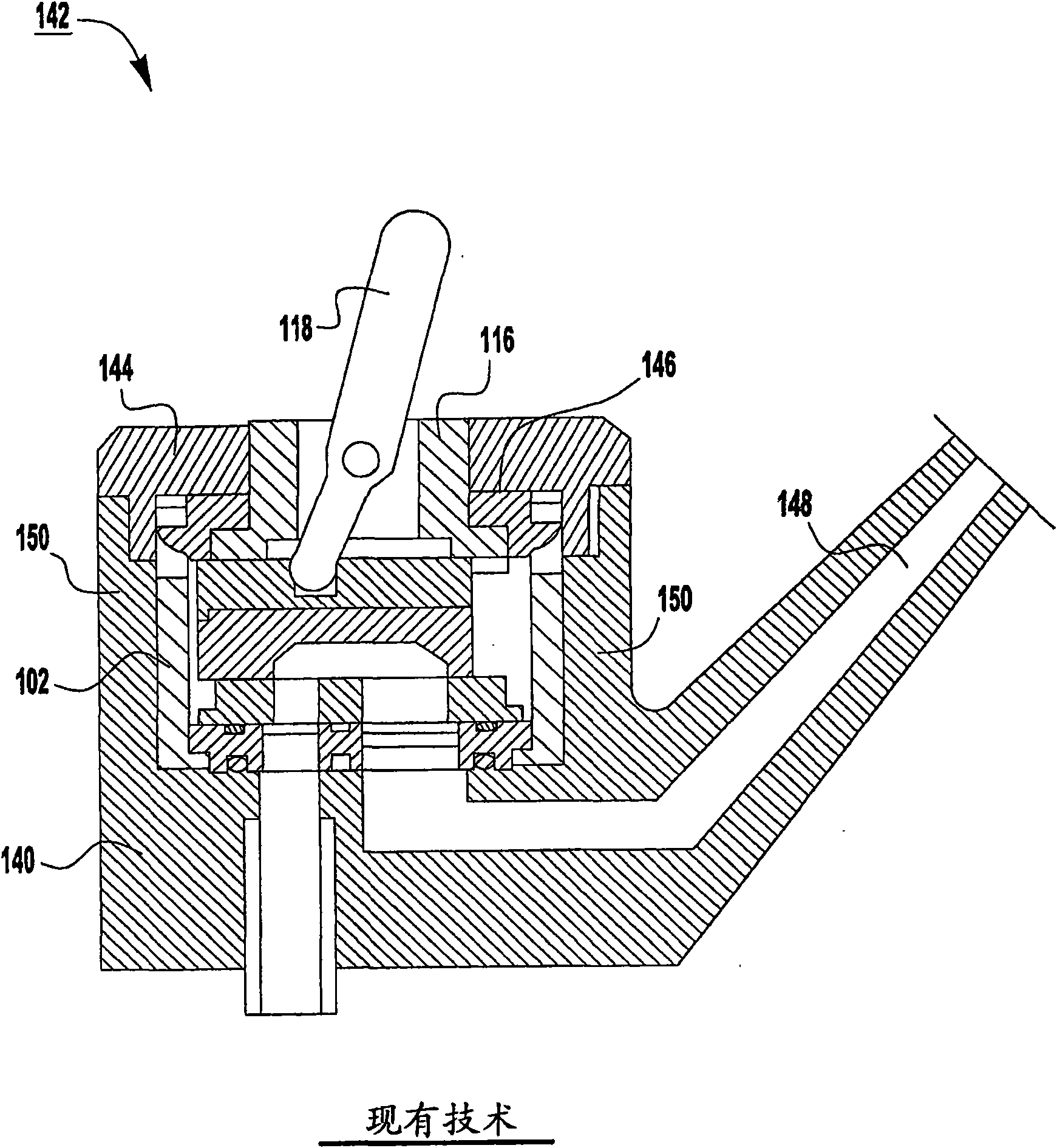

[0057] The single handle spool 200 according to the exemplary embodiment has a low contact point for securing the spool 200 in the valve body 240 . Therefore, the spool 200 can overcome the disadvantages of the conventional valve box with high contact points.

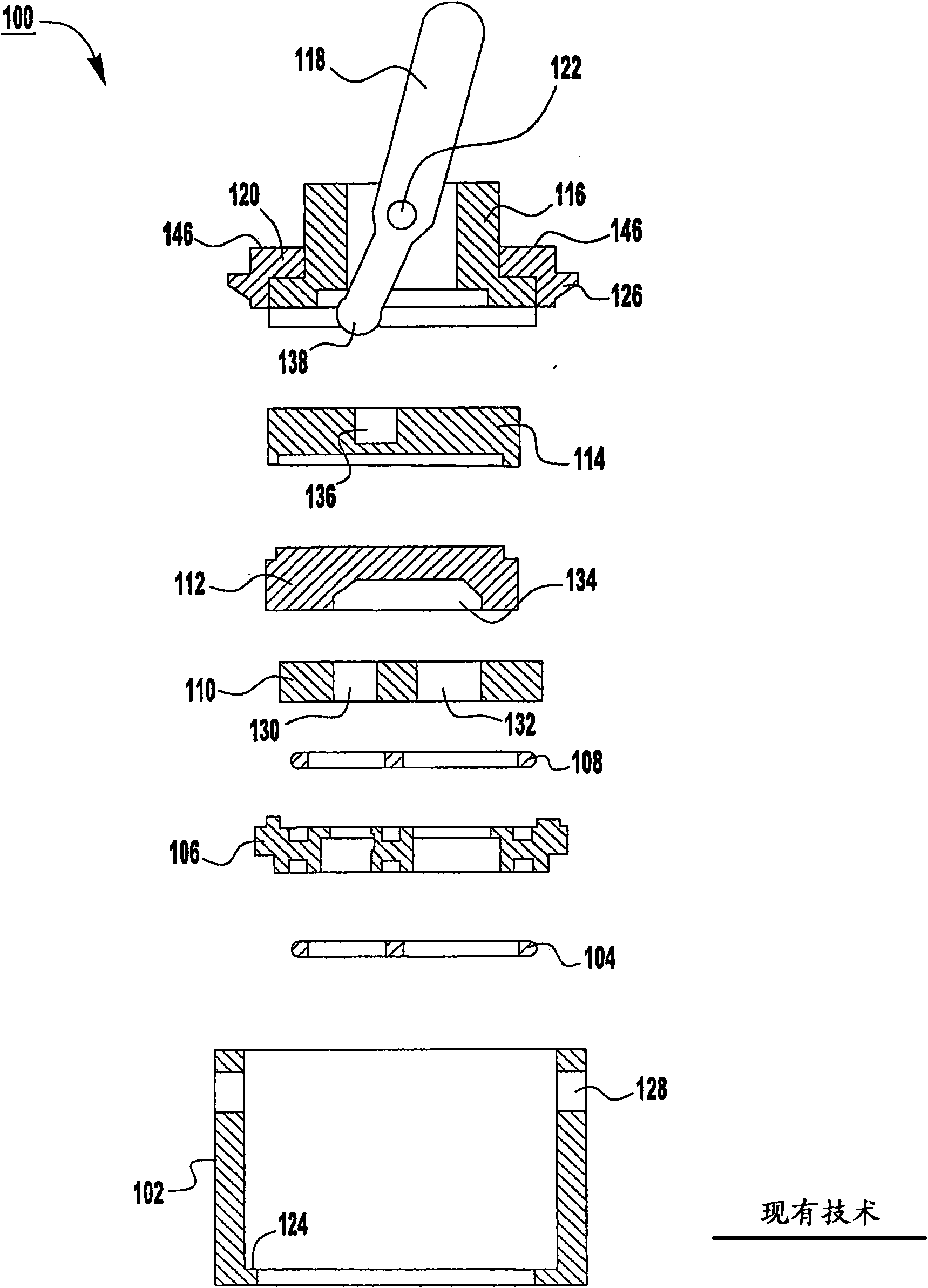

[0058] Such as figure 2 with 10A As shown in FIG. 10C , the exemplary cartridge 200 has several separate components including a housing 202 , a bulb 204 , a pin 206 , a spring 208 , a bushing 210 , a flow plate 212 , a manifold 214 , and a base seal 216 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com